| –

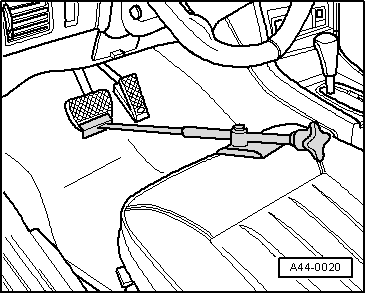

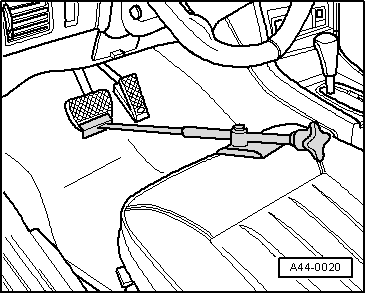

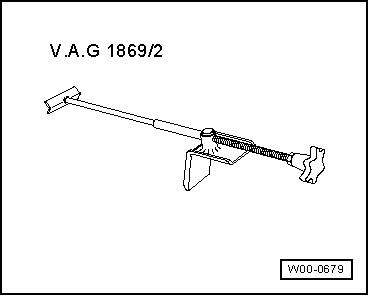

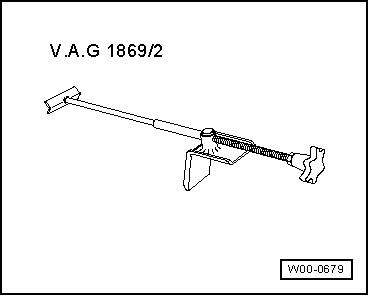

| Insert brake pedal actuator -V.A.G 1869/2- between brake pedal and driver's seat. Depress brake pedal by at least 60 mm. |

| –

| Connect hose of bleeder bottle to bleeder screws of front left and rear left brake calipers. |

Note | This will release the pressure in the hydraulic unit. |

| –

| Close bleeder screws (front left and rear left). |

| –

| Do not remove brake pedal actuator -V.A.G 1869/2-. |

| –

| As protection against escaping brake fluid, place a sufficient number of lint-free cloths in area beneath control unit and hydraulic unit. |

| –

| Unclip brake lines from bracket on plenum chamber partition panel. |

| –

| Unscrew all brake lines from hydraulic unit. |

WARNING | Do not bend the brake lines in the vicinity of the hydraulic unit. |

|

| –

| Seal brake lines and threaded holes using sealing plugs from repair kit. |

| –

| Release electrical connector and unplug connector from control unit. |

Note | t

| Make sure brake fluid does not get into connector housing of control unit. This can result in corrosion of the contacts and failure of the system. |

| t

| Use compressed air to carefully clean connector housing if necessary. |

| –

| Slacken nuts on rubber buffers on bracket for hydraulic unit. |

| –

| Detach hydraulic unit together with control unit from bracket and rubber buffers and remove from vehicle. |

| Installation is performed in reverse sequence; note the following: |

Note | t

| Do not remove sealing plugs from new hydraulic unit until corresponding brake line is ready to be fitted. |

| t

| If sealing plugs are removed from hydraulic unit sooner, brake fluid may escape and it may no longer be possible to fill and bleed the unit properly. |

| –

| Attach bracket to hydraulic unit. |

| –

| Insert hydraulic unit together with control unit in rubber buffers on bracket in vehicle. |

Note | To facilitate installation, moisten the rubber mountings in the bracket slightly with water. |

| –

| Tighten nuts on rubber buffers on bracket for hydraulic unit. |

| –

| Remove sealing plugs from new hydraulic unit. |

Note | To facilitate installation, first insert all the brake lines in the hydraulic unit and then tighten the brake line connections. |

| –

| Insert all brake lines. |

| –

| Secure all brake line connections. |

Note | Final control diagnosis can be used to establish whether line connections have been interchanged. |

| –

| Clip brake lines into bracket on plenum chamber partition panel. |

| –

| Remove brake pedal actuator -V.A.G 1869/2-. |

| –

| If the control unit is being renewed, the corresponding routine must be started on the vehicle diagnostic, testing and information system -VAS 505 x- in the Guided Functions. |

| –

| After attaching brake lines to hydraulic unit, perform final control diagnosis with Vehicle diagnostic, testing and information system -VAS 505 x-, Guided Functions. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note