| –

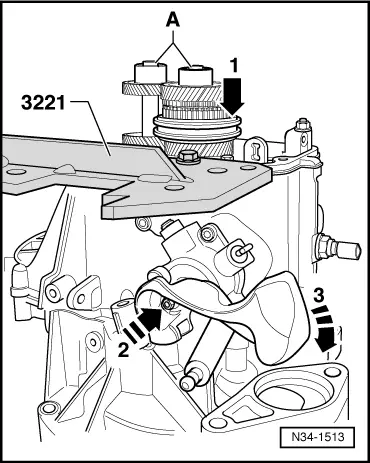

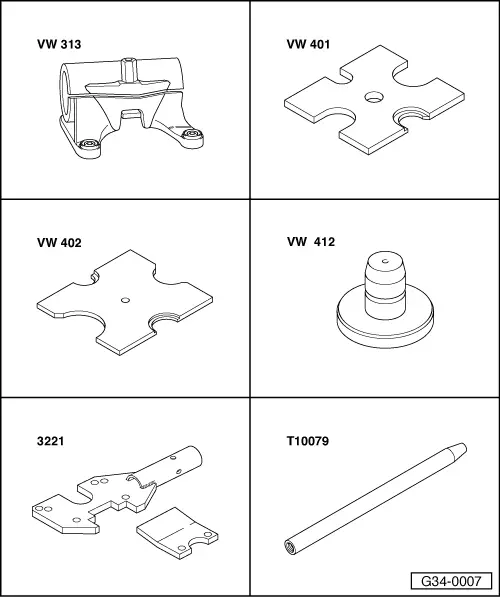

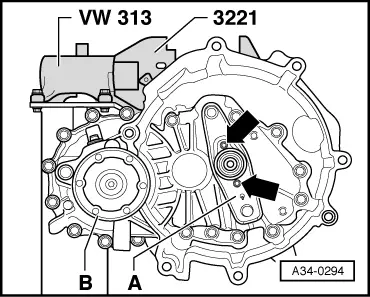

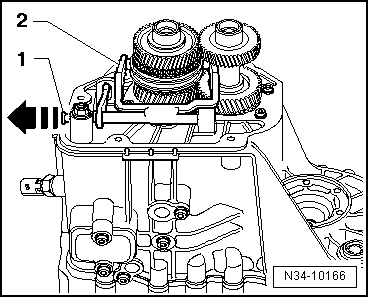

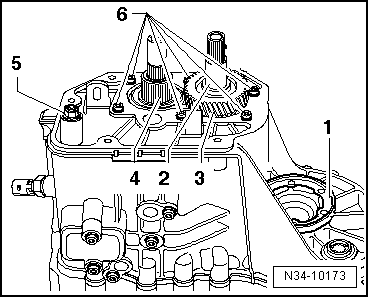

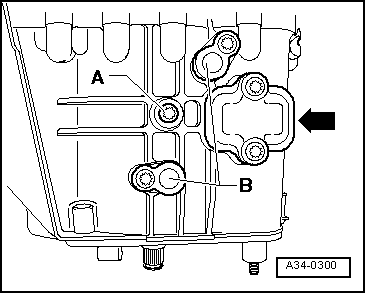

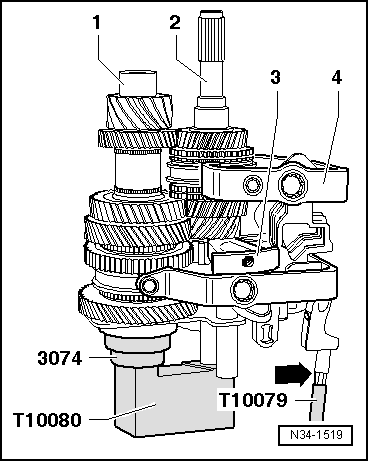

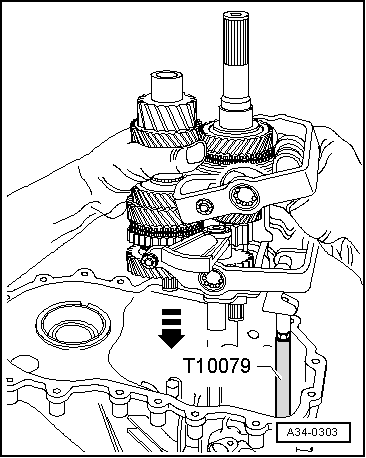

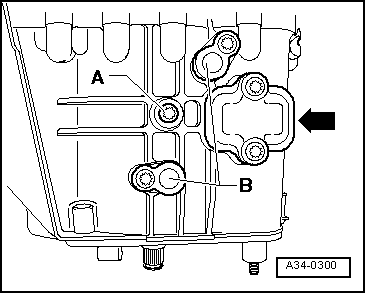

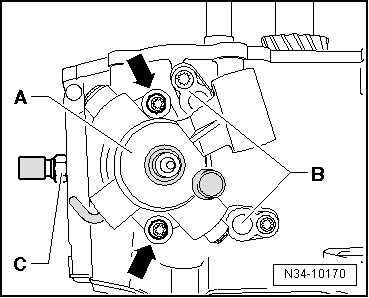

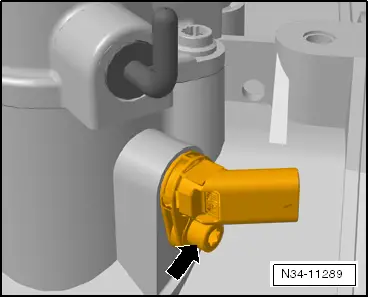

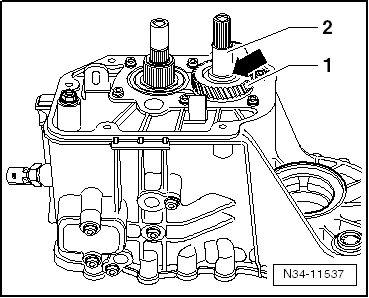

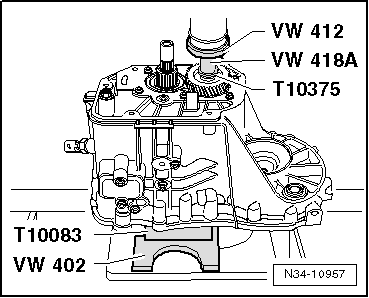

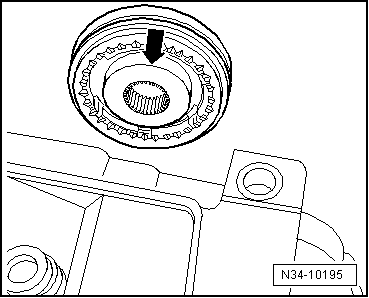

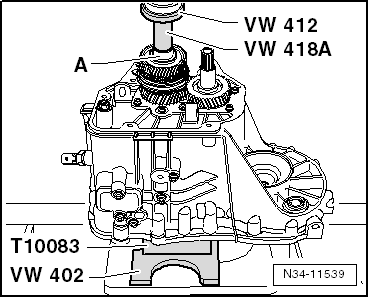

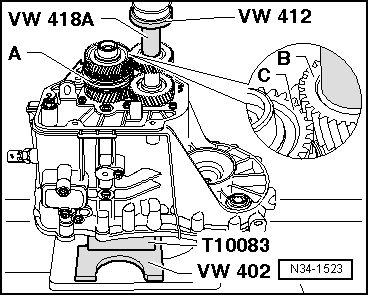

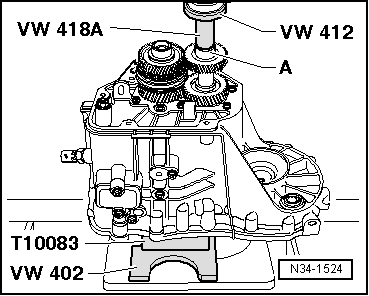

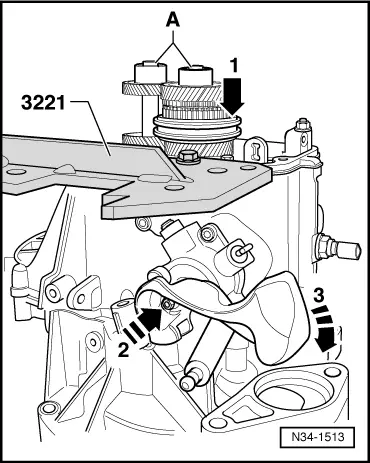

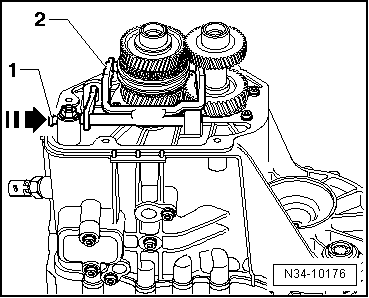

| Remove bolts -A- for inner bearing races on input and output shafts. To do this, engage 5th gear -arrow 1- and 1st gear -arrows 2- and -3-. |

| –

| The input and output shafts are both locked when these two gears are engaged. The two bolts can now be loosened. |

Note | t

| If the shafts are not being renewed, carefully clean residual locking compound out of tapped holes using a thread tap. |

| t

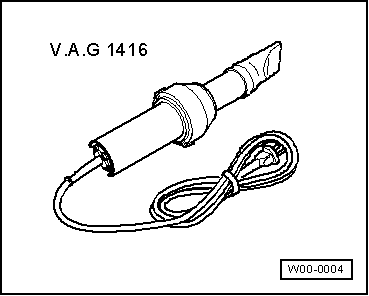

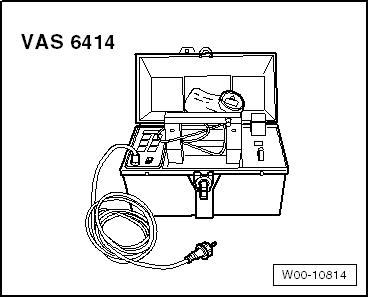

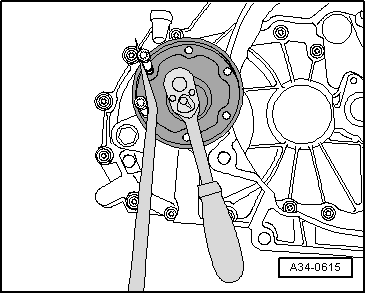

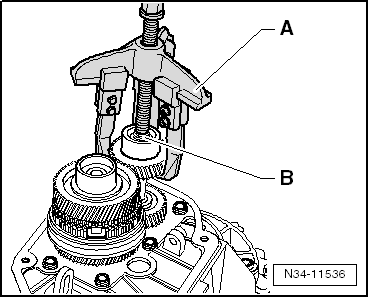

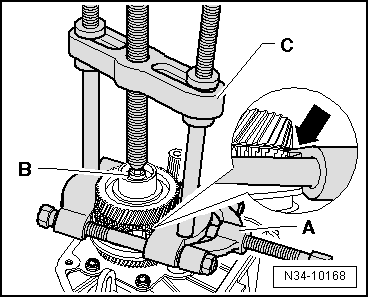

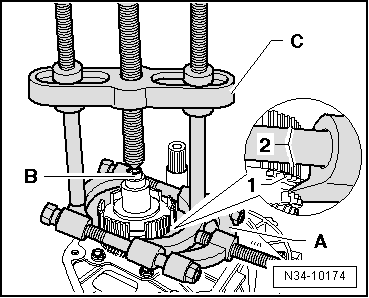

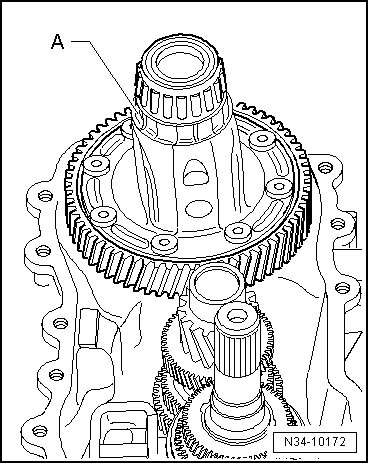

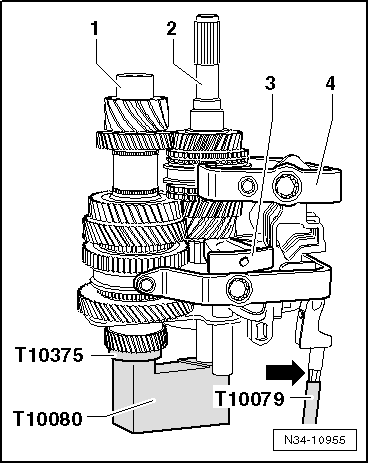

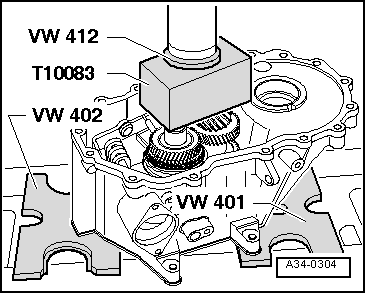

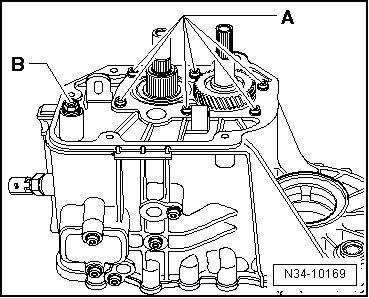

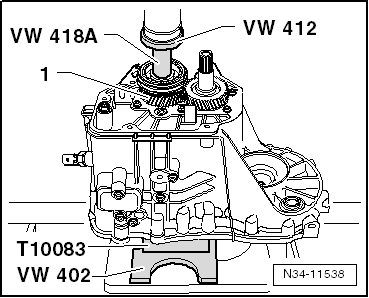

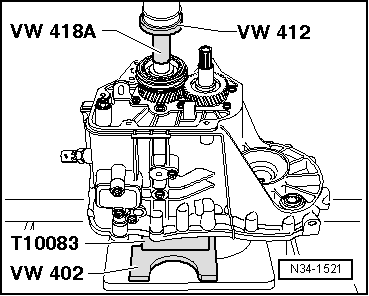

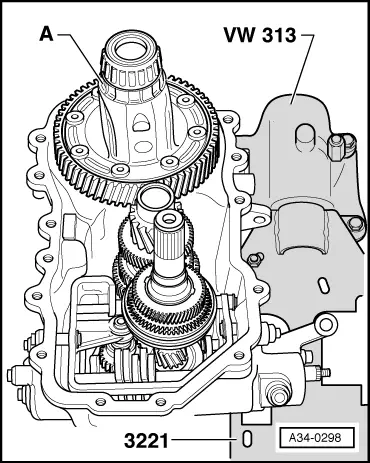

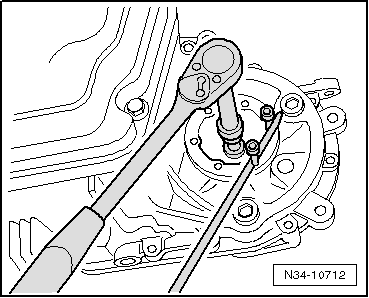

| Pull off 6th gear wheel using three-arm puller -Kukko 30/1-. While doing so, heat gear wheel using hot air blower -V.A.G 1416-. |

| t

| If necessary, 6th gear wheel can be pulled off part of the way using two-arm puller -Kukko 204/2- until spindle of puller reaches stop. Then remove completely using three-arm puller -Kukko 30/1-. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING