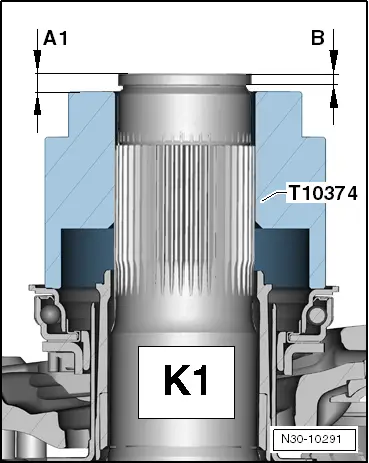

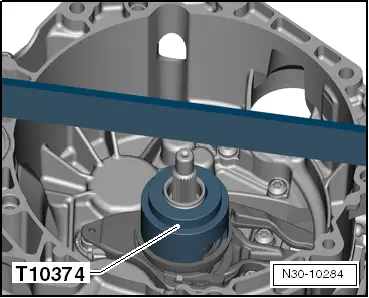

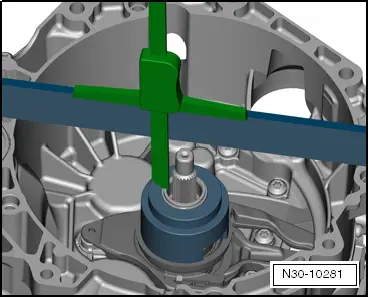

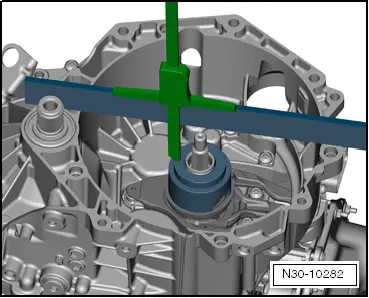

| Adjusting position of engagement bearings „K 1 and K 2“ |

| The position of the engagement bearings must be adjusted in the following cases: |

| t

| Clutch has been renewed. |

| t

| Engaging levers have been renewed. |

| t

| Retainer for engaging levers has been renewed. |

| t

| Engagement bearings have been renewed. |

Note | No adjustment is necessary if all aforementioned components have merely been removed and installed again. |

| t

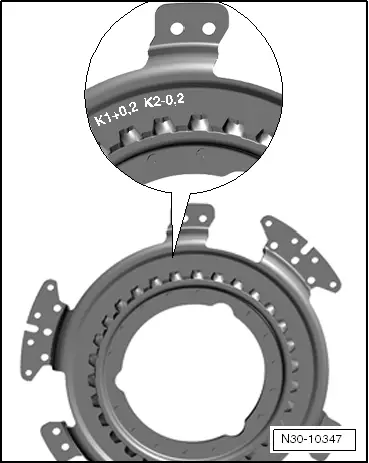

| The position of the engagement bearings can be compared to the clutch play of a mechanical manual gearbox. On the 7-speed dual clutch gearbox 0AM, there are tolerances for the engagement system of the gearbox, for the gearbox itself and for the dual clutch. The tolerances must be considered separately during the adjustment procedure. |

| t

| In the following the procedure for determining all necessary dimensions (on the gearbox) is described in order to select the required shim. In addition, the tolerances determined by the manufacturer for the clutch are given; the tolerances for the gearbox and for the clutch together determine the thickness of the shim. |

| Special tools and workshop equipment required |

| t

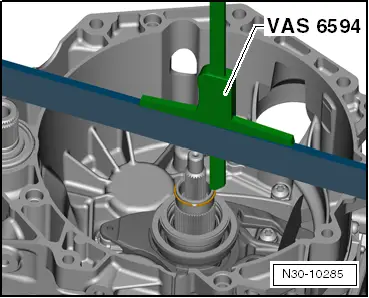

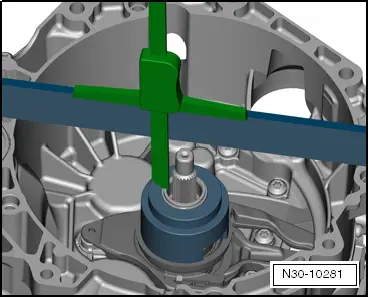

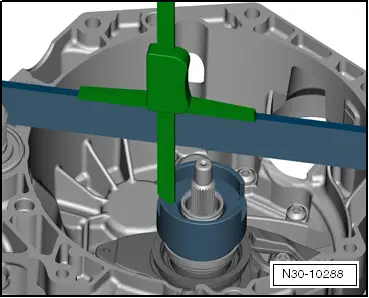

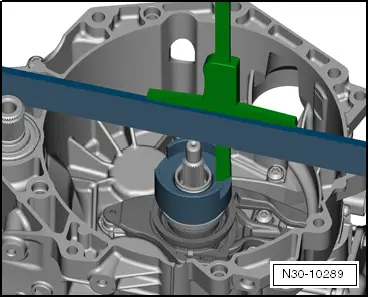

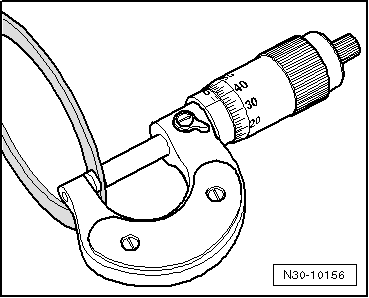

| Depth gauge, digital (300 mm) -VAS 6594- |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution