A1

| Component | Nm | |

| Bolts/nuts | M6 | 9 |

| M7 | 15 | |

| M8 | 22 | |

| M10 | 40 | |

| M12 | 65 | |

|

|

|

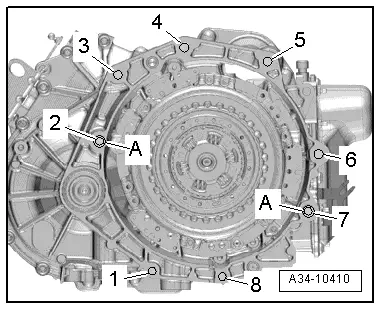

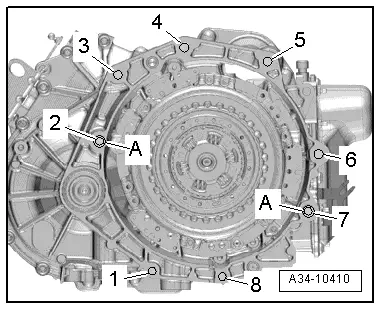

| Item | Bolt | Nm |

| 1, 8 | M10x50 | 40 |

| 2, 6, 7 | M12x65 | 80 |

| 3, 4, 5 | M12x55 | 80 |

| A | Dowel sleeves for centralising | |

Note

Note

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

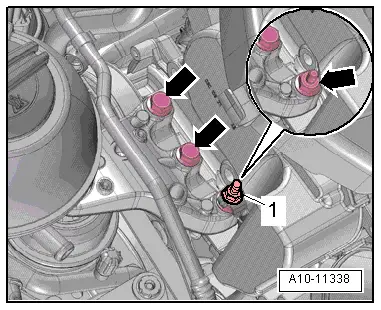

Caution

Caution