A1

|

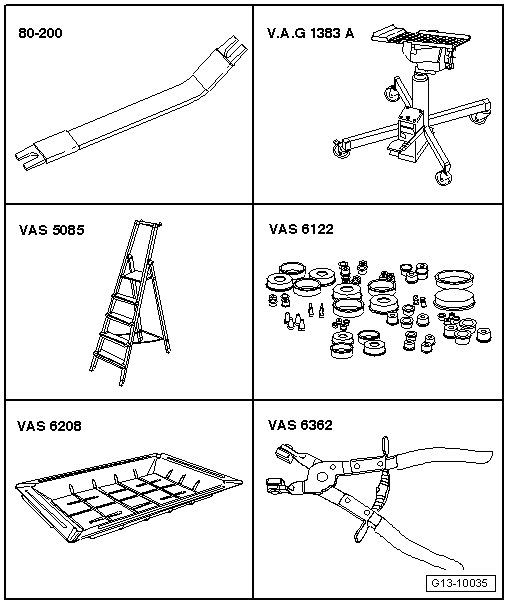

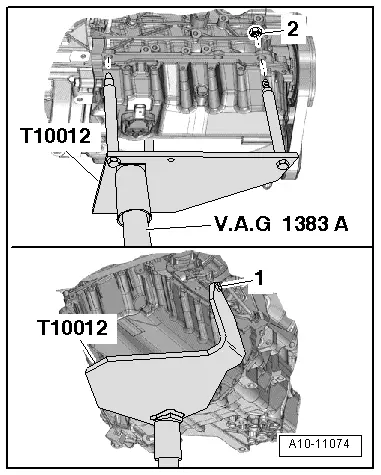

| Special tools and workshop equipment required |

| t | Removal lever -80 - 200- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Stepladder -VAS 5085- |

| t | Engine bung set -VAS 6122- |

| t | Drip tray for workshop hoist -VAS 6208- |

| t | Hose clip pliers -VAS 6362- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Caution

Caution WARNING

WARNING