Caution | Make sure excess sealant does not contaminate camshaft bearings. |

| The beads of sealant must not be thicker than specified. |

|

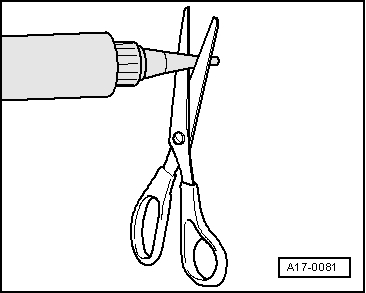

| –

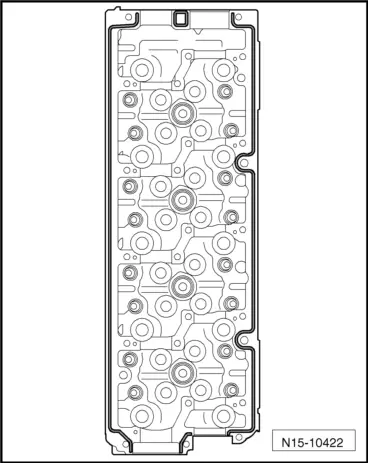

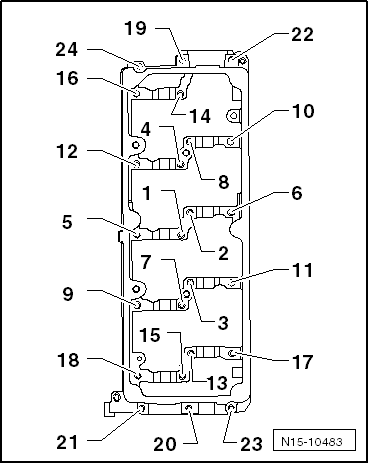

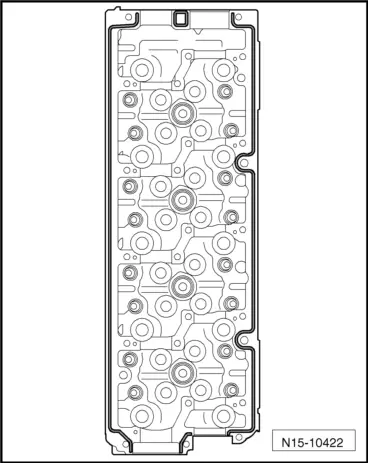

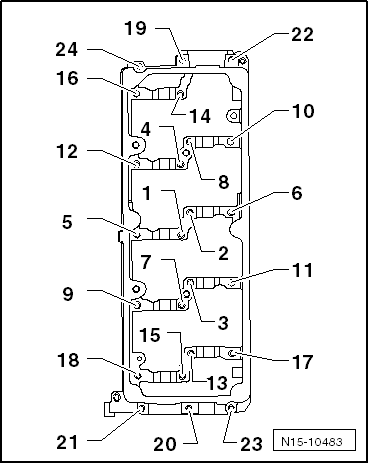

| Apply beads of sealant onto clean sealing surfaces of cylinder head as shown in illustration. |

| l

| Thickness of sealant beads: 2 ... 3 mm. |

Note | t

| The retaining frame should be fitted and secured without delay, as the sealant starts hardening immediately. |

| t

| After installing the retaining frame, wait about 30 minutes for the sealant to dry. |

| –

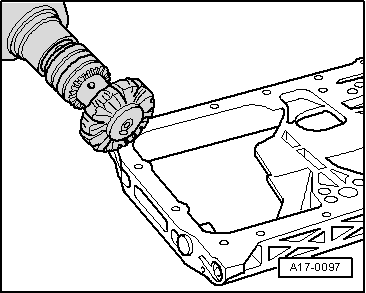

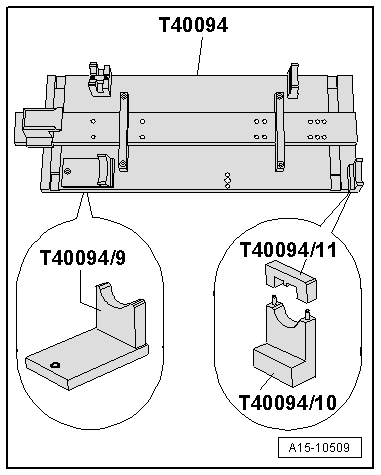

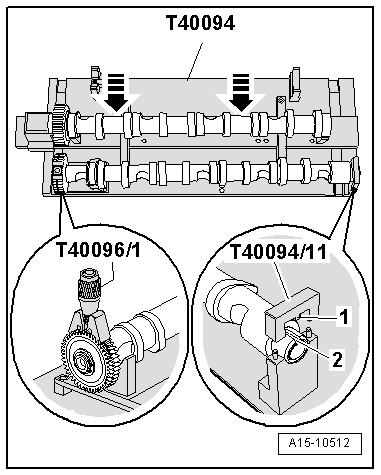

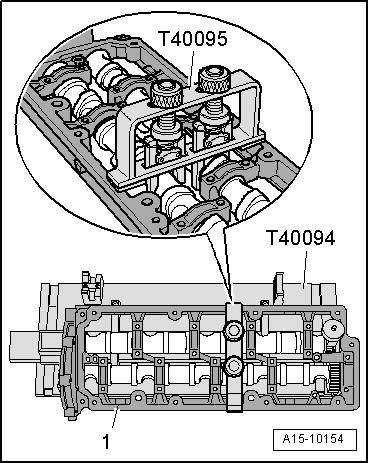

| Take camshafts together with retaining frame, camshaft fitting tool -T40095- and, if necessary, clamping tool -T40096/1- out of camshaft fitting tool -T40094- and insert components carefully into cylinder head. |

|

|

|

Note

Note

Note

Note

Caution

Caution WARNING

WARNING