| –

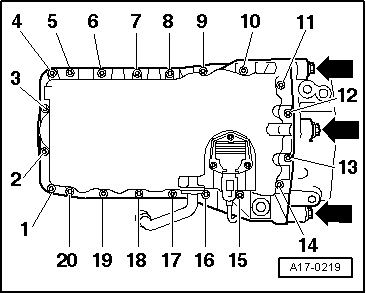

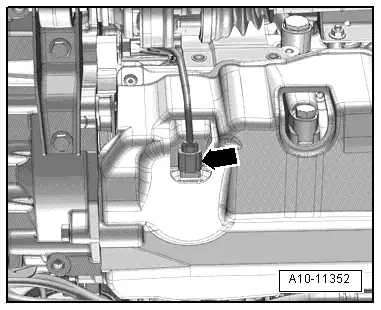

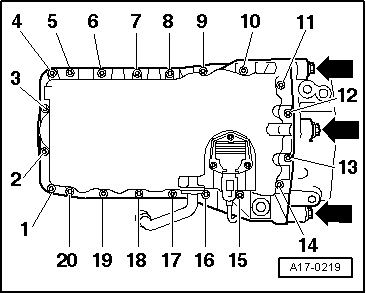

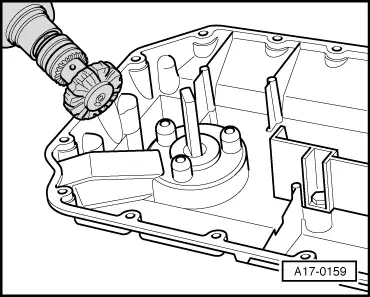

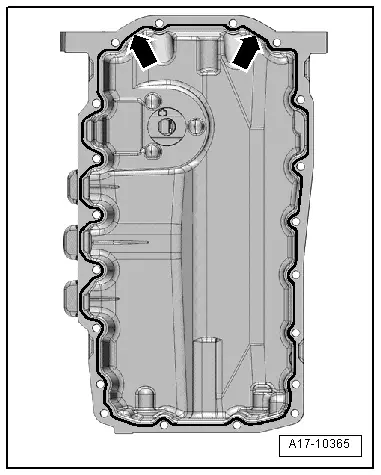

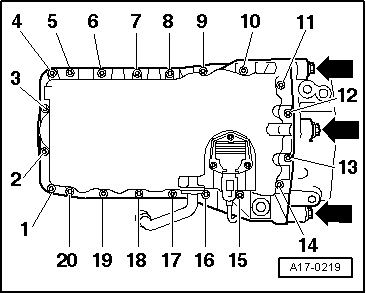

| Fit sump and tighten bolts → Fig.. |

| l

| The sump must make flush contact with intermediate plate/gearbox flange. |

Note | t

| When installing sump with engine removed from vehicle, ensure that sump is positioned flush with cylinder block at flywheel end. |

| t

| After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

| Remaining installation steps are carried out in reverse sequence; note the following: |

Note | –

| Install pump for exhaust gas recirculation cooler -V400- → Chapter. |

| –

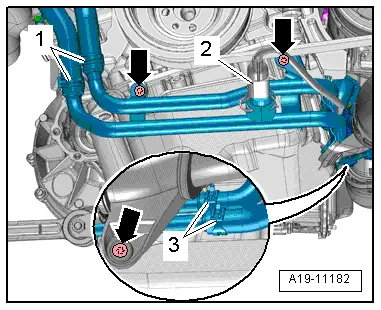

| Install coolant pipes (right-side) → Chapter. |

| –

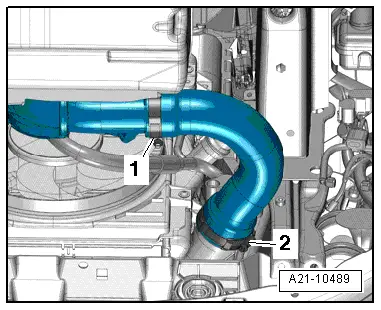

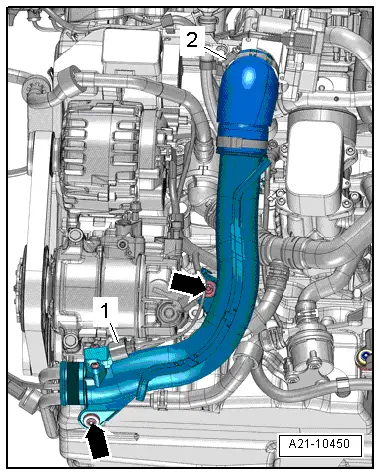

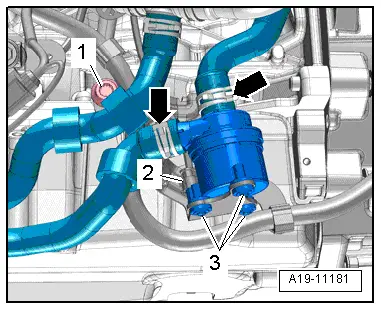

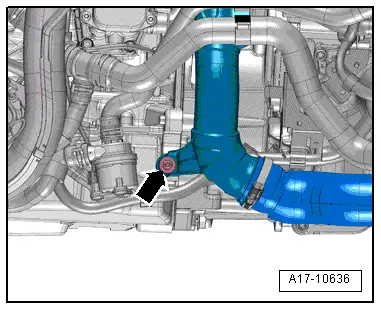

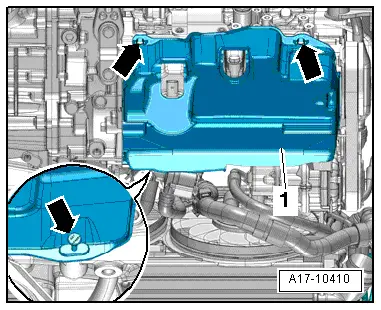

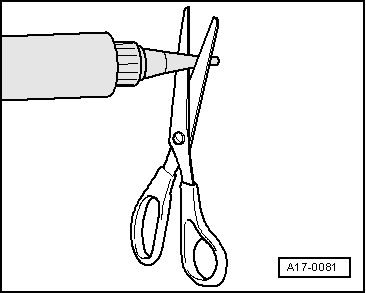

| Install air hoses with screw-type clips → Fig.. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution WARNING

WARNING