| –

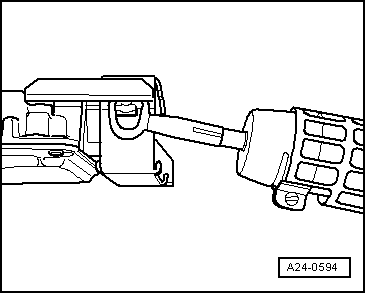

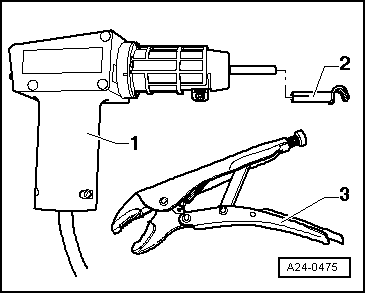

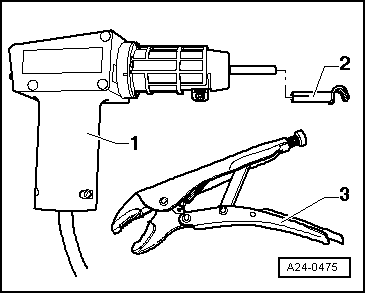

| Then grasp bolt head with vice-grip pliers and unscrew shear bolt. |

| –

| Repeat procedure for second shear bolt. |

| –

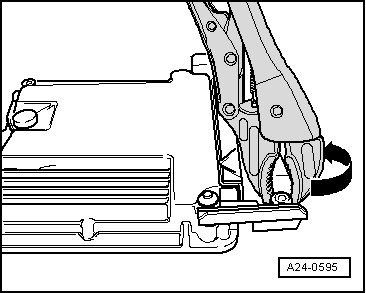

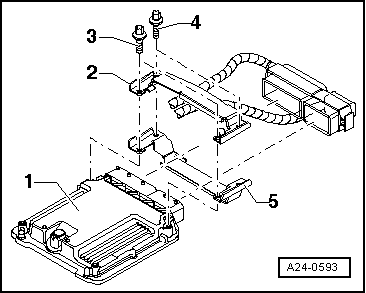

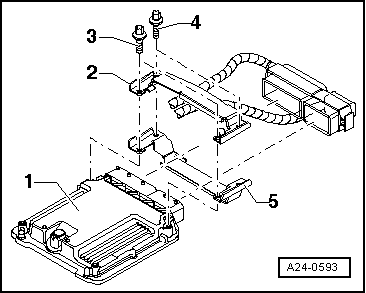

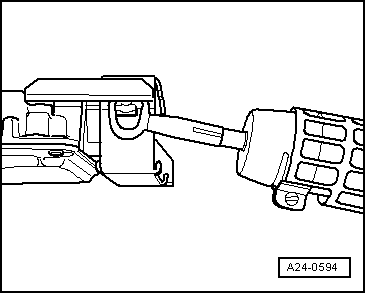

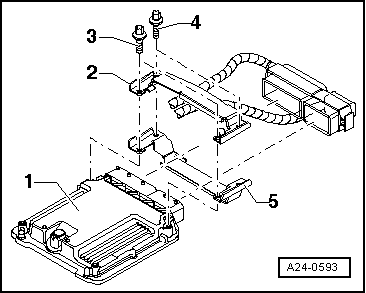

| Detach protective housing from multi-pin connectors. |

| –

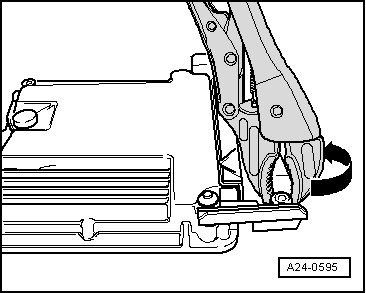

| Unscrew the two shear bolts screwed into the engine control unit (they do not need to be heated). |

| Installation is carried out in the reverse order; note the following: |

| –

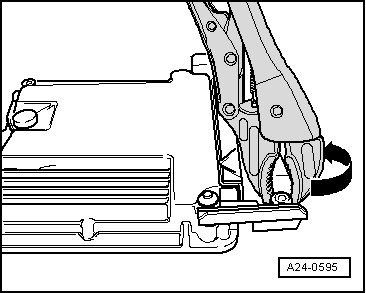

| After installation, the protective housing must be re-fitted on the engine control unit -J623-. |

| –

| Clean threaded holes for shear bolts to remove any residue from locking fluid. This can be done using a thread tap. |

| –

| Always use new shear bolts. |

| After installing a new engine control unit, the following operation must be performed: |

| –

| Activate engine control unit via a vehicle diagnostic tester in „Guided Functions“ mode, „Replace engine control unit“. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note