| –

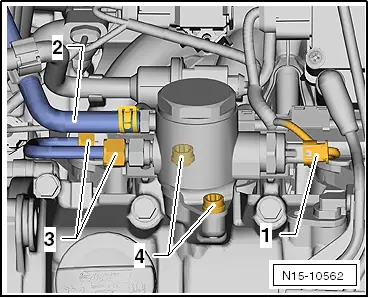

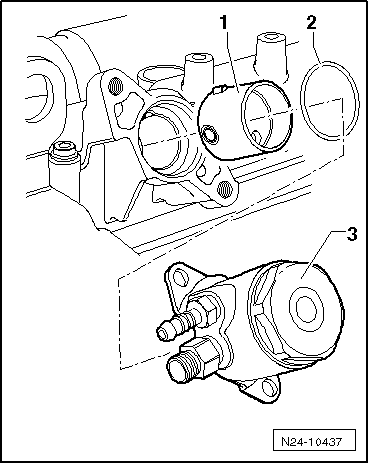

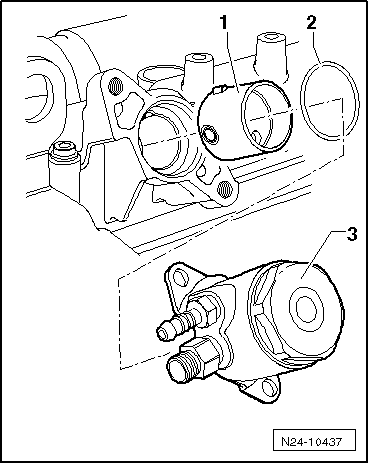

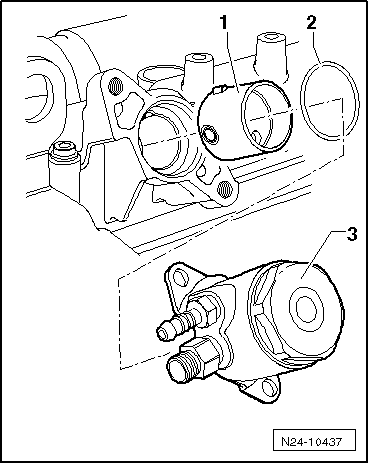

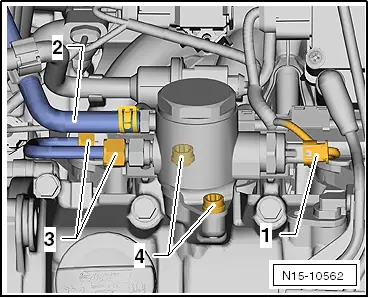

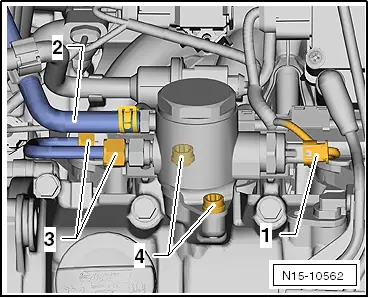

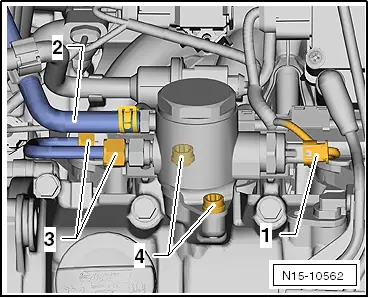

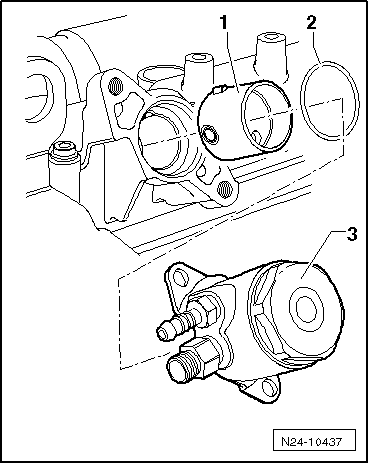

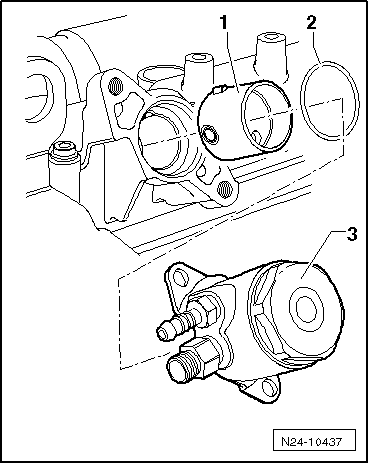

| Pull high-pressure pump -3- and roller tappet -1- out of camshaft housing. |

Caution | When removing or installing the high-pressure pump, take hold of it only by the housing. |

| If the piston spring assembly of the high-pressure pump comes loose, the high-pressure pump will leak and must be renewed. |

|

Note | Renew O-ring for high-pressure pump. |

| –

| Check roller tappet for damage and renew if necessary. |

| –

| Lubricate roller tappet -1- with clean engine oil. |

| –

| Insert lubricated roller tappet -1- into camshaft housing. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note