A2

|

Note

Note

|

|

| Possible deviation from specification | Possible causes of fault | Fault elimination | ||||||||||||||||||

|

|

| ||||||||||||||||||

|

| |||||||||||||||||||

|

|

Note

Note| t | If no fault is found for this problem, clean refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter). |

| t | Check the measured values of the evaporator output temperature sender -G263- and actuation of -N280-. If the measured value of the evaporator output temperature sender -G263- is not OK, the evaporator may ice up or the cooling output is not attained. |

| t | If, after renewing the expansion valve, operation of the air conditioning system is not OK when the test is repeated (re-fit old expansion valve), clean the refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter). Then renew the air conditioner compressor and receiver. |

| t | In this case, the evaporator may ice up although the correct quantity of refrigerant is present in the refrigerant circuit. |

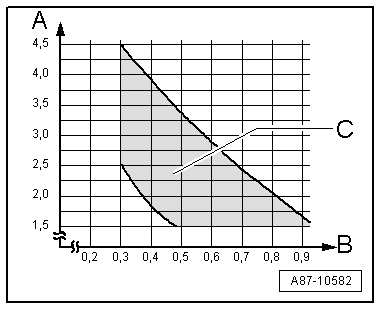

| t | If the expansion valve is defective (permanently closed or does not open sufficiently), -N280- is actuated to maximum output and the low pressure drops to the value in the graph or below (the air conditioner compressor draws off refrigerant from the low-pressure end). As however refrigerant cannot flow via the expansion valve, the cooling output is not attained and the high pressure may also not increase or only increase slightly due to the absence of energy conversion → Vehicle diagnostic tester („self-diagnosis“ or „Guided Fault Finding“ function for air conditioner) and → Heating, air conditioning; Rep. gr.87 or → Air conditioning; Rep. gr.87 (vehicle-specific workshop manual). |

| Possible deviation from specification | Possible causes of fault | Fault elimination | ||||||||||||

|

|

| ||||||||||||

|

| |||||||||||||

|

|

Note

Note

|

| Possible deviation from specification | Possible causes of fault | Fault elimination | ||||||||||||||||||||||||||||||||||||

|

|

|

Note

Note| t | If the function of the air conditioning system is not OK when the test is repeated, renew expansion valve and receiver. |

| t | With this fault, the evaporator may ice up although the quantity of refrigerant in the circuit is OK. |

| t | If the expansion valve is defective (permanently closed or does not open sufficiently), the air conditioner compressor regulating valve -N280- is actuated to maximum output and the low pressure drops to the value in the graph or below (the air conditioner compressor draws off refrigerant from the low-pressure end). As however refrigerant cannot flow via the expansion valve, the cooling output is not attained and the high pressure may also not increase or only increase slightly due to the absence of energy conversion → Vehicle diagnostic tester („self-diagnosis“ or „Guided Fault Finding“ function for air conditioner) and → Heating, air conditioning; Rep. gr.87 or → Air conditioning; Rep. gr.87 (vehicle-specific workshop manual). |

| t | If there is too much refrigerant oil in the circuit, drain the air conditioner compressor and renew the receiver. After cleaning the refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter), add the correct amount of refrigerant oil to the circuit → Chapter. |

| Possible deviation from specification | Possible causes of fault | Fault elimination | ||||||||||||||||

|

|

| ||||||||||||||||

|

|

Note

Note| t | It is not initially necessary to clean the refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter) when this problem occurs. Normally, there is only a small quantity of moisture in the system which can be removed by lengthy evacuation. |

| t | If a problem involving moisture in the refrigerant circuit only occurs after a lengthy operating period or only infrequently (low pressure drops below specification and evaporator ices up), it is sufficient to renew the dryer in the receiver (adjust quantity of refrigerant oil). Subsequently, evacuate refrigerant circuit for at least 3 hours. |

| t | In this case, the evaporator may ice up although the correct quantity of refrigerant is present in the refrigerant circuit. |

| t | A problem with evaporator output temperature sender -G263- can also cause icing-up of refrigerant circuit. If this problem is encountered, also pay attention to the measured value of the evaporator output temperature sender -G263- → Vehicle diagnostic tester („self-diagnosis“ or „Guided Fault Finding“ function for air conditioner) and → Heating, air conditioning; Rep. gr.87 or → Air conditioning; Rep. gr.87 (vehicle-specific workshop manual). |

| Possible deviation from specification | Possible causes of fault | Fault elimination | ||||||||||||||||||||||||||||

|

|

|

Note

Note| t | Observe the following regarding fault „High pressure normal, low pressure too low“: This fault may cause the evaporator to ice up although the amount of refrigerant in the circuit is OK. |

| t | If the problem is with -N280- (the regulating valve is not actuated but the air conditioner compressor operates nevertheless), the refrigerant circuit does not have to be cleaned (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter). It is sufficient in this case to renew the air conditioner compressor (heed quantity of refrigerant oil in air conditioner compressor). |

| t | If the expansion valve is defective (permanently closed or does not open sufficiently), -N280- is actuated to maximum output and the low pressure drops to the value in the graph or below (the air conditioner compressor draws off refrigerant from the low-pressure end). As refrigerant cannot however flow via the expansion valve, the cooling output is not attained and the high pressure may either not increase or only slightly due to the absence of energy conversion. |

| t | Check the measured values of the evaporator output temperature sender -G263- and actuation of -N280-. If the measured value of the evaporator output temperature sender -G263- is incorrect, the evaporator may ice up or the cooling output is not attained → Vehicle diagnostic tester („self-diagnosis“ or „Guided Fault Finding“ function for air conditioner) and → Heating, air conditioning; Rep. gr.87 or → Air conditioning; Rep. gr.87 (vehicle-specific workshop manual). |

| Possible deviation from specification | Possible causes of fault | Fault elimination | ||||||||||||||||||||||||||||||||||||

|

|

|

Note

Note| t | This fault may also be caused by too much refrigerant oil in the circuit. Overfilling with refrigerant oil may occur if, for example, the air conditioner compressor has been renewed without adjusting the quantity of refrigerant oil. |

| t | If the expansion valve is defective (permanently closed or does not open sufficiently), -N280- is actuated to maximum output and the low pressure drops to the value in the graph or below (the air conditioner compressor draws off refrigerant from the low-pressure end). As however refrigerant cannot flow via the expansion valve, the cooling output is not attained and the high pressure may also not increase or only increase slightly due to the absence of energy conversion → Vehicle diagnostic tester („self-diagnosis“ or „Guided Fault Finding“ function for air conditioner) and → Heating, air conditioning; Rep. gr.87 or → Air conditioning; Rep. gr.87 (vehicle-specific workshop manual). |

| Possible deviation from specification | Possible causes of fault | Fault elimination | ||||||||||||||||||

|

|

| ||||||||||||||||||

|

|

Note

Note| t | Overfilling with refrigerant oil may occur if, for example, the air conditioner compressor has been renewed without adjusting the quantity of refrigerant oil. |

| t | If the expansion valve is defective (permanently open), the evaporator temperature is no longer regulated such that only refrigerant in gas form exits from the evaporator. Under certain usage conditions, liquid droplets may then be drawn in by the air conditioner compressor and cause noise (liquid cannot be compressed). |

| t | If there is too much refrigerant oil in the circuit, drain the air conditioner compressor and renew the receiver. After cleaning the refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter), add the correct amount of refrigerant oil to the circuit → Chapter. |