A2

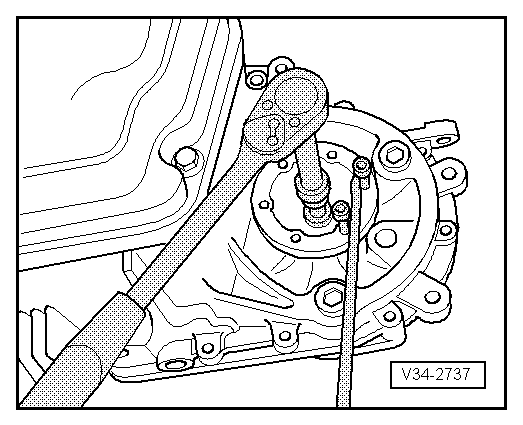

| Renewing flange shaft oil seal (right-side) - one-piece oil seal and sleeve |

| Special tools and workshop equipment required |

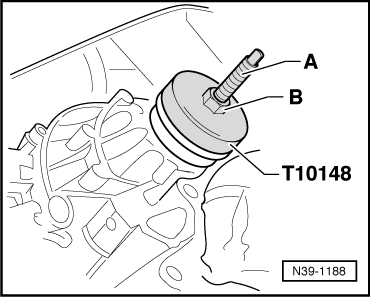

| t | Thrust piece -T10148- |

| t | Spindle from assembly device -3066- |

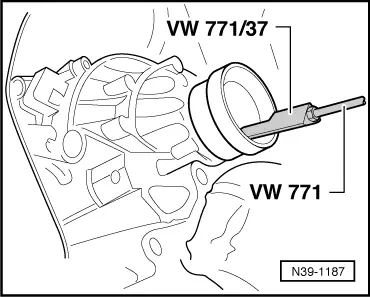

| t | Multi-purpose tool -VW 771- |

| t | Puller hook -VW 771/37- |

| t | Torque wrench -V.A.G 1331- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

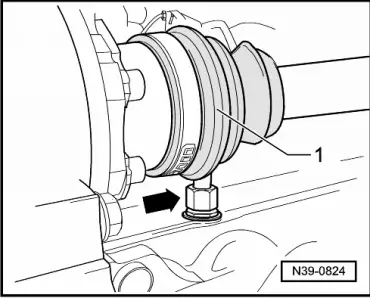

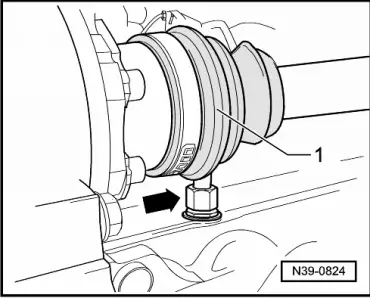

| Flange shaft to gearbox (countersunk bolt) | 25 Nm | |

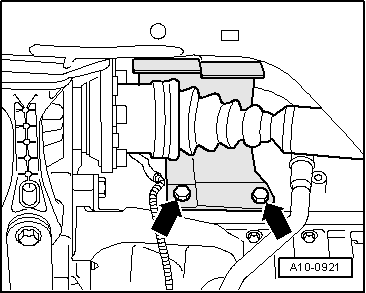

| Protective cover for right inner constant velocity joint to engine | M8 M10 | 20 Nm 35 Nm |