| –

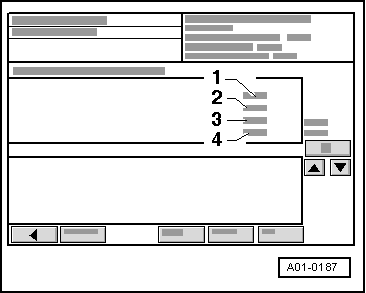

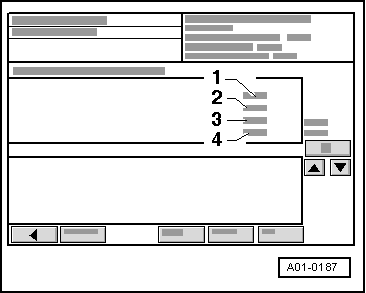

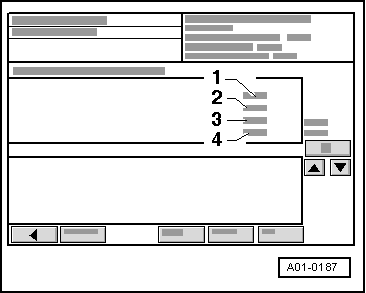

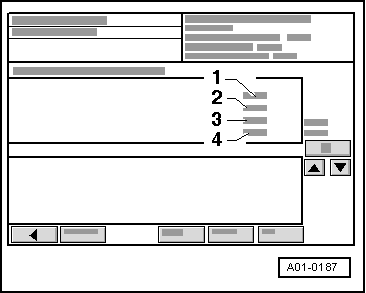

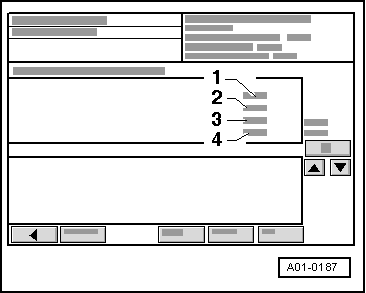

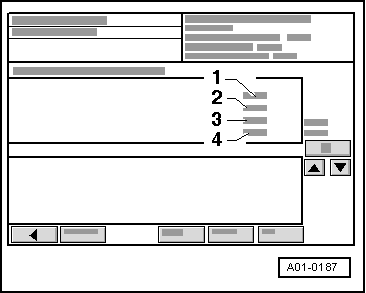

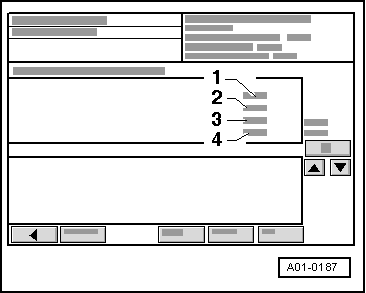

| By pressing the ↑ key twice, switch to measured value block 004 → Anchor. |

| –

| Check the last digit (on the far right) of the display in display zone -2-. |

| l

| Specified value: Display “XXXXXXX1” = brake pedal operated. |

| –

| Release the brake pedal. |

| l

| Specified value: Display “XXXXXXX0” = brake pedal not operated. |

Note | Ignore the digits represented by “X”. |

| If readout is not as described: |

| –

| Interrogate fault memory of engine control unit. |

| –

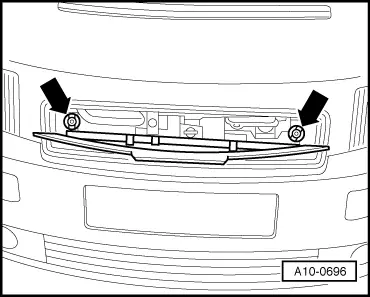

| Check the brake pressure switch -F270- in the electrical test, test step 9 → Anchor. |

| If the vehicle still does not start: |

| If the vehicle still does not start: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note