| –

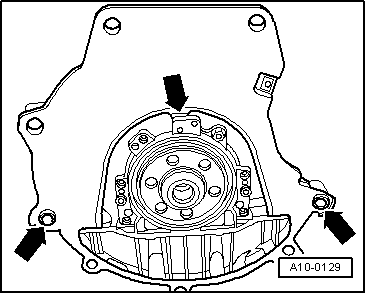

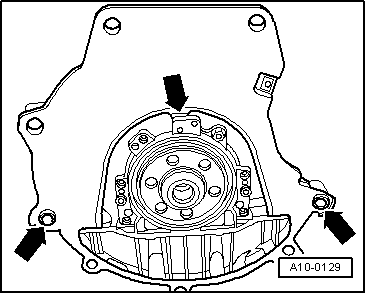

| Fit intermediate plate onto dowel sleeves -arrows-. |

| –

| When swivelling engine/gearbox assembly in place, ensure sufficient clearance from gear actuator and starter catalytic converter. |

| –

| Install support arm with engine mounting → Chapter. |

| –

| Install starter catalytic converter together with main catalytic converter → Chapter. |

| –

| Observe notes on procedures required after connecting battery → Rep. Gr.27. |

Caution | Do not use a battery charger to boost starting. There is danger of damaging the vehicle's control units. |

|

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine oil or gearbox oil may be used, but do not use lubricant containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15 %. |

|

|

|

Note

Note Note

Note

Caution

Caution