A2

Note

Note

|

Note

Note

|

|

|

|

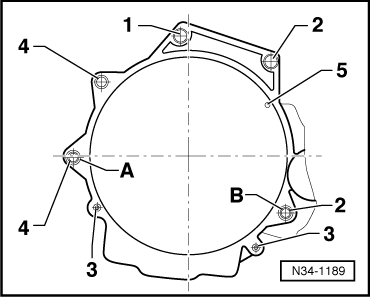

| Item | Bolt | Nm | ||||||

| 1 1), 2 | M12x55 | 80 | ||||||

| 3 | M10x50 | 40 | ||||||

| 4 1)2) | M12x150 | 80 | ||||||

| 5 3) | M6x12 | 10 | ||||||

| A, B | Dowel sleeves for centralising | |||||||

| ||||||||

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | ||

| Bolts/nuts | M6 | 9 | |

| M7 | 15 | ||

| M8 | 20 | ||

| M10 | 40 | ||

| M12 | 65 | ||

| Except for the following: | |||

| Battery plus (+) cable to starter | 16 | ||

| Earth wire to gearbox | 22 | ||

| Bracket for wiring harness to coolant hose/pipe connection | 10 | ||

| Drive shaft heat shield to cylinder block | 33 | ||

| Air pipe to: | Turbocharger | 8 | |

| Sump | 8 | ||

| Body | 8 | ||

| Engine cover panel to bracket | 5.5 | ||

Caution

Caution