A2

Note

Note

|

| Component | Nm | |

| Bolts/nuts | M6 | 10 |

| M7 | 15 | |

| M8 | 22 | |

| M10 | 40 | |

| M12 | 65 | |

|

|

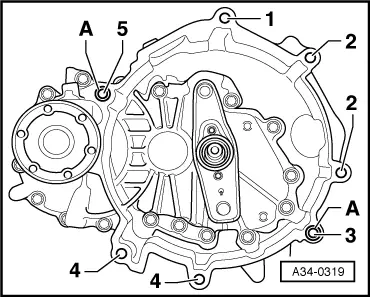

| Item | Bolt | Nm | ||

| 1, 3 | M12x65 | 80 | ||

| 2 1) | M12x135 | 80 | ||

| 4 | M10x50 | 40 | ||

| 5 | M12x80 | 80 | ||

| A | Dowel sleeves for centralising | |||

| ||||

Note

Note

|

Note

Note

|

|

Note

Note

|

| Component | Nm | |

| Bolts/nuts | M6 | 10 |

| M7 | 15 | |

| M8 | 22 | |

| M10 | 40 | |

| M12 | 65 | |

|

|

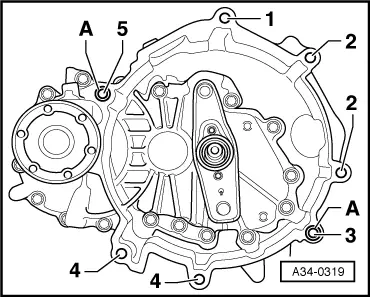

| Item | Bolt | Nm | ||

| 1, 3 | M12x65 | 80 | ||

| 2 1) | M12x135 | 80 | ||

| 4 | M10x50 | 40 | ||

| 5 | M12x80 | 80 | ||

| A | Dowel sleeves for centralising | |||

| ||||

Note

Note

|

Note

Note

|

|