Note | t

| If a good seating pattern cannot be obtained by grinding the valve seats (lapping), they must be refaced (machined). |

| t

| When servicing engines with leaking valves, it is not sufficient to machine (reface) the valve seats and renew the valves. The valve guides must also be checked for wear. This is particularly important on high-mileage engines → Chapter. |

| t

| Valve seats should only be machined to the extent required to give a proper seating pattern. |

| t

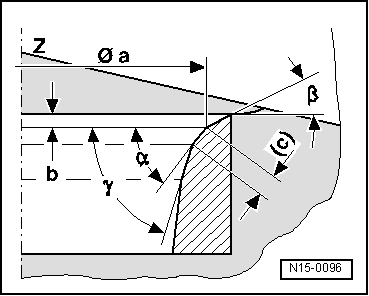

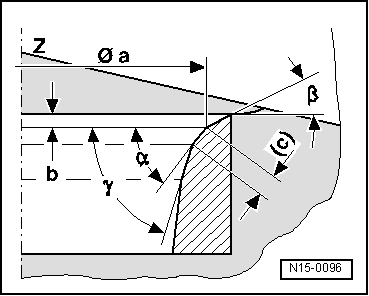

| The maximum permissible machining dimension must be calculated before starting work. |

| t

| If the machining dimension is exceeded, the function of the hydraulic valve play compensation can no longer be guaranteed and the cylinder head must be renewed. |

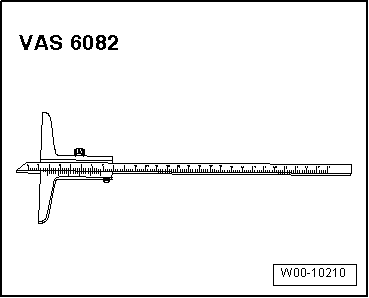

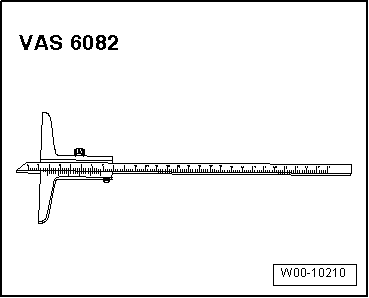

| Special tools and workshop equipment required |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note