| –

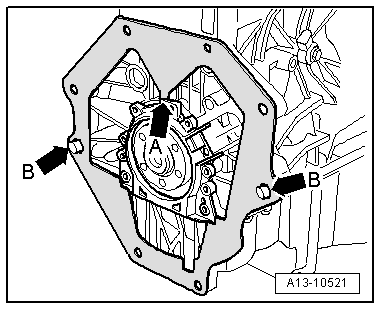

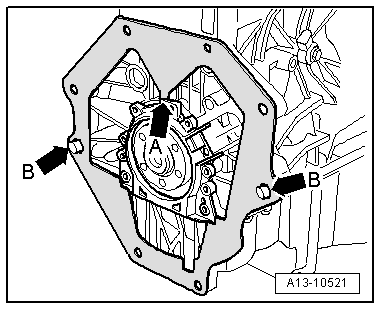

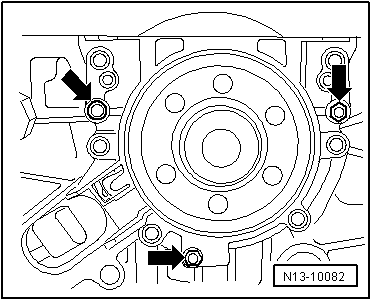

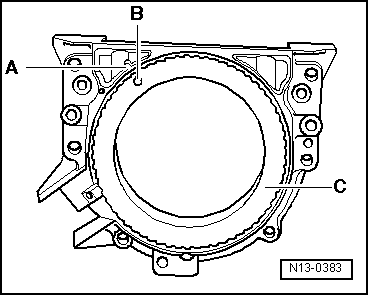

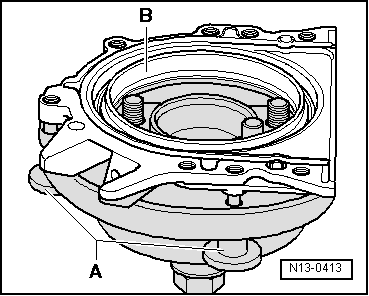

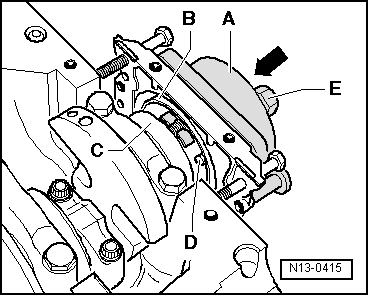

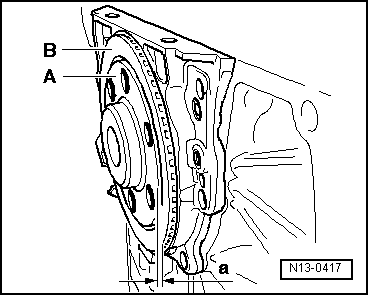

| Remove bolts for sealing flange. |

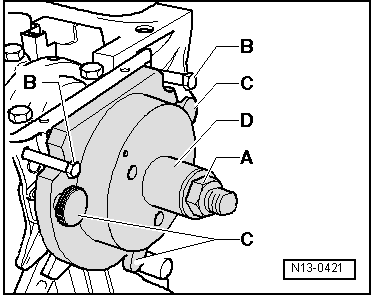

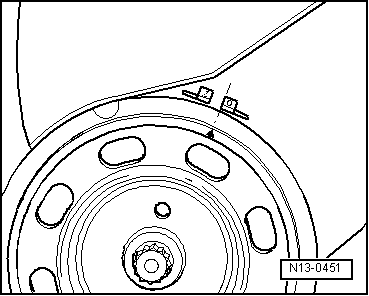

Note | The sealing flange is pressed off the crankshaft together with the sender wheel. |

| –

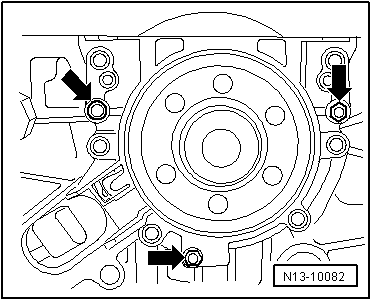

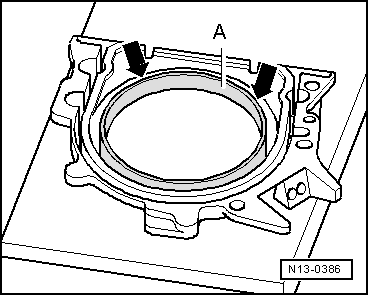

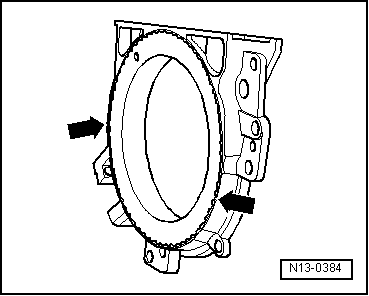

| To press off, screw 3 bolts M6x35 -arrows- alternately into sealing flange not more than 1/2 turn at a time. |

| –

| Take off sealing flange with sender wheel. |

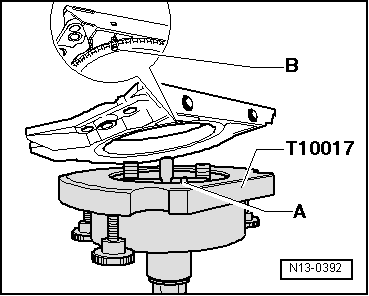

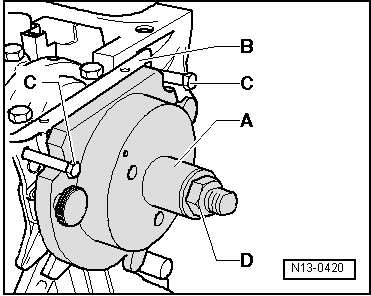

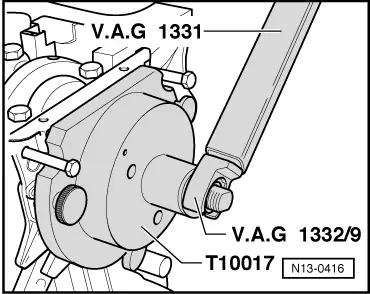

| Pressing in sealing flange with sender wheel |

Note | t

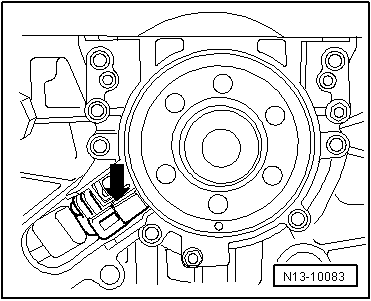

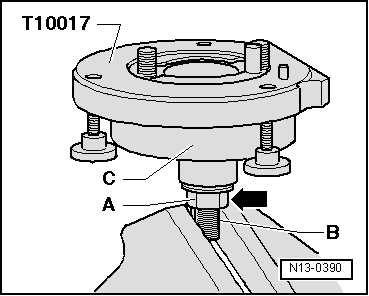

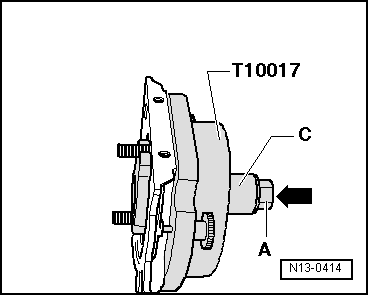

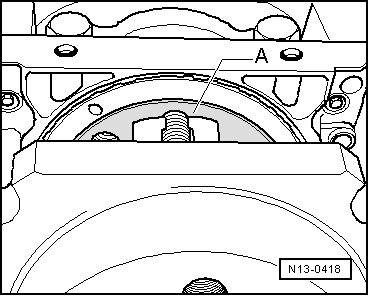

| The sealing flange with PTFE oil seal is fitted with a sealing lip support ring. This support ring acts as an assembly sleeve and must not be removed before installation. |

| t

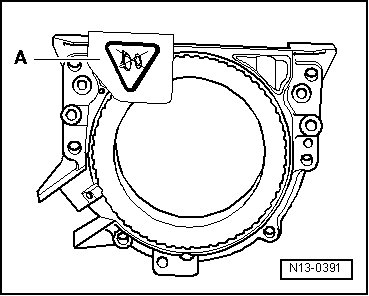

| Sealing flange and sender wheel must not be separated or rotated out of position after removal from packaging. |

| t

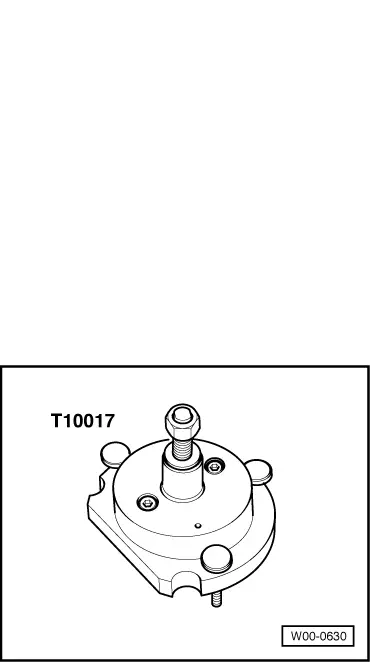

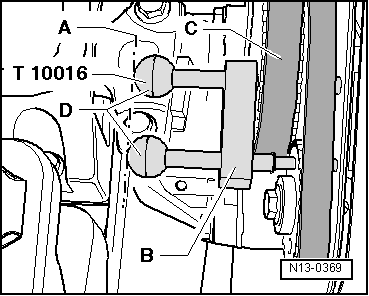

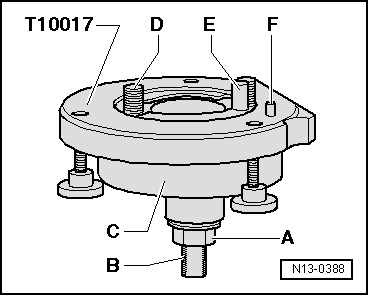

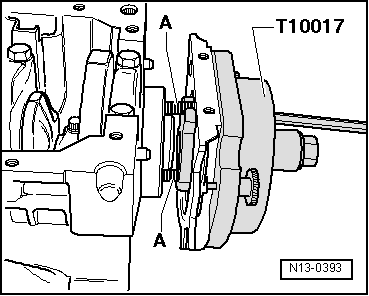

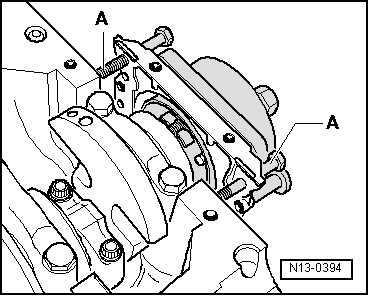

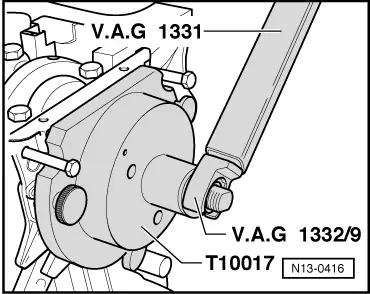

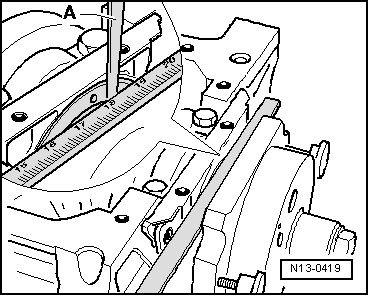

| The sender wheel is held in its installation position by a locating pin on the assembly tool -T10017-. |

| t

| The sealing flange and oil seal are one unit and can only be replaced together with the sender wheel. |

| t

| The assembly tool -T10017- is held in the correct position relative to the crankshaft by a guide pin which is inserted into a hole in the crankshaft. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note