A2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

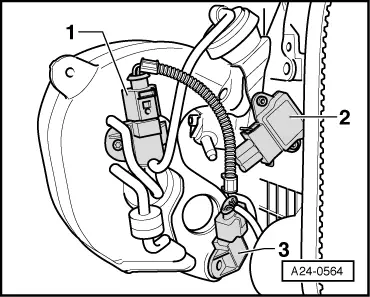

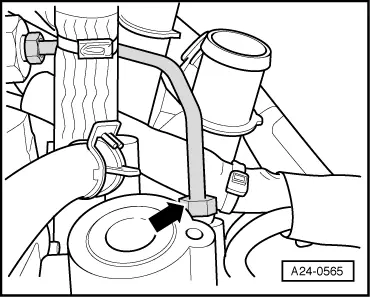

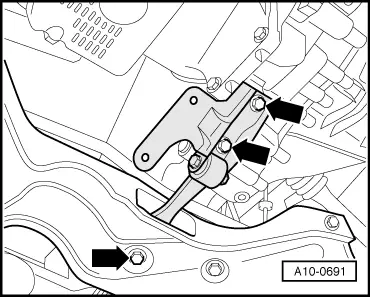

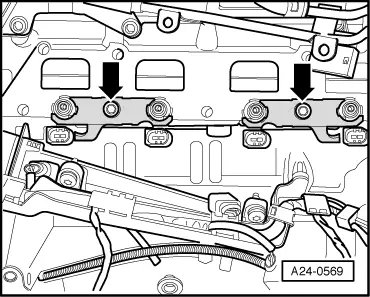

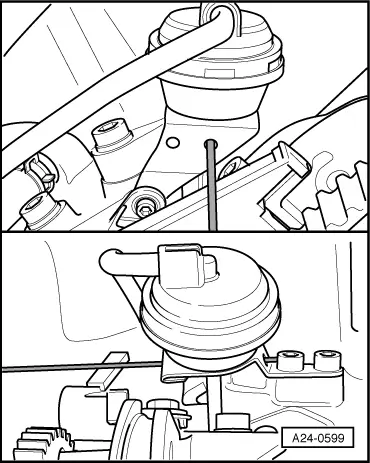

Note: The central bolt -3- must not be slackened.

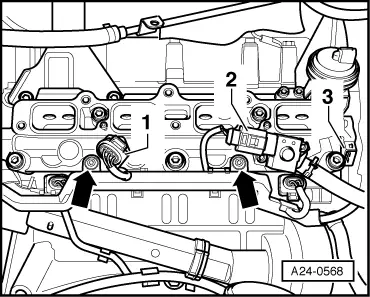

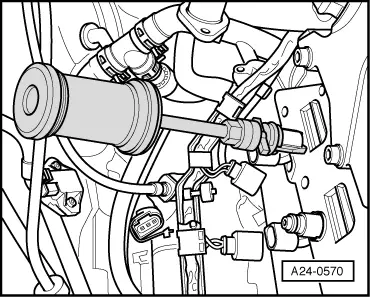

Removing and installing high-pressure injectors Notes: |

|

|

|

|

|

|

|

|

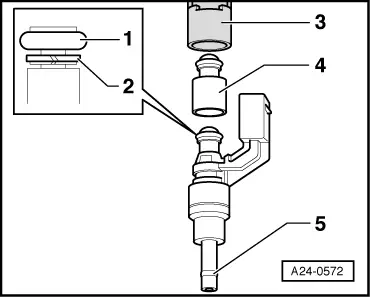

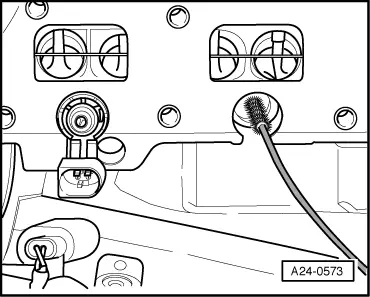

Replacing O-ring and Teflon ring on high-pressure injector |

|

|

Replacing O-rings The O-rings from the spacer sleeves and from the high-pressure injector must always be replaced.

Replacing support ring The support ring only has to be replaced if it has been damaged.

Note: Pay attention to correct installation position. The flat side without shoulder must face the O-ring. Replacing Teflon ring The Teflon ring used as a combustion chamber seal must always be replaced if the high-pressure injector is reused.

Note: The groove must not be damaged, otherwise the high-pressure injector must be replaced. |

|

|

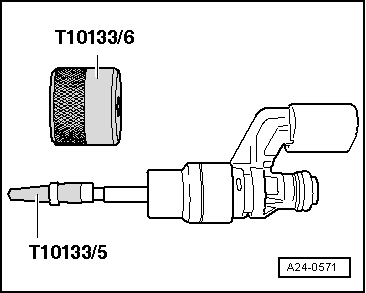

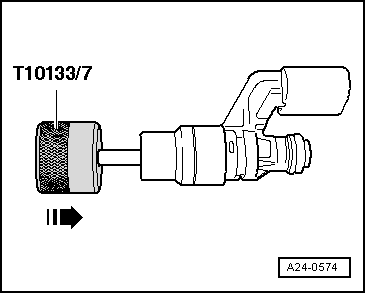

Step 1 of Teflon ring calibration (adaption) is performed using the special tool T 10133/7. |

|

|

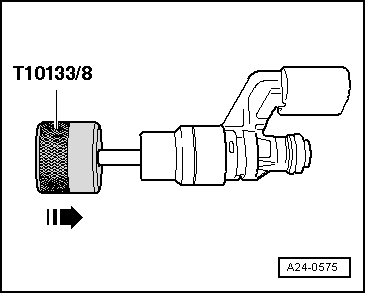

Step 2 of Teflon ring calibration (adaption) is performed using the special tool T 10133/8. |

|

|

|

|

|

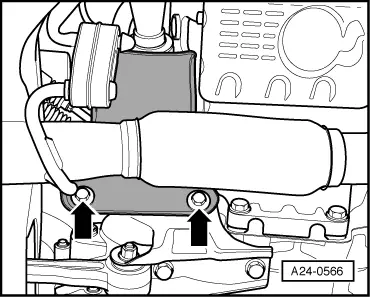

Installing high-pressure injection units and lower part of intake manifold / upper part of intake manifold Install in reverse order Important: The following points must always be observed. |

|

|

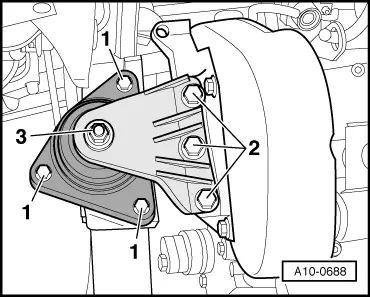

Torques, see exploded views: |