A3 Mk1

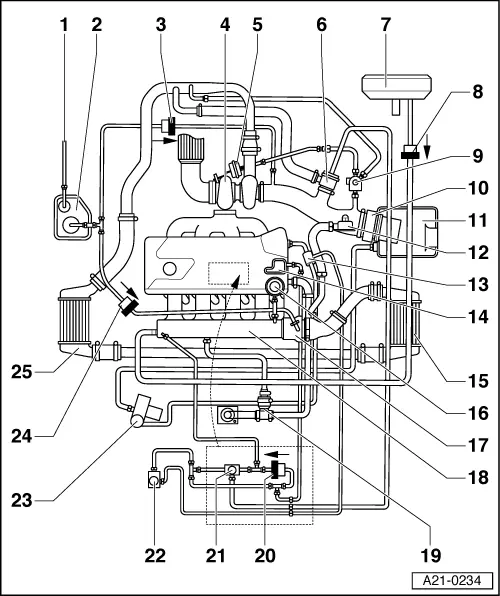

| Diagram of connections for charge pressure control system and vacuum system |

| Vehicles with engine codes APY, AUL |

| 1 - | From fuel tank |

| 2 - | Activated charcoal filter |

| q | With activated charcoal filter system solenoid valve 1 -N80- |

| 3 - | Non-return valve |

| q | Between activated charcoal filter and intake pipe upstream of turbocharger |

| q | Installation position: arrow points direction of flow |

| 4 - | Turbocharger |

| q | Checking charge pressure → Chapter |

| 5 - | Vacuum unit for charge pressure control |

| 6 - | Mechanical air recirculation valve |

| q | Checking → Chapter |

| 7 - | Brake servo |

| 8 - | Non-return valve |

| q | Between brake servo and intake manifold |

| q | Installation position: arrow points direction of flow |

| 9 - | Charge pressure control solenoid valve -N75- |

| q | Checking → Chapter |

| 10 - | Air mass meter -G70- |

| 11 - | Air cleaner |

| 12 - | Pressure control valve for crankcase breather system |

| 13 - | Combination valve for secondary air system |

| 14 - | Vacuum reservoir |

| q | Bolted to cylinder head cover |

| 15 - | Charge air cooler |

| q | With charge pressure sender -G31- |

| q | Checking charge pressure sender -G31- → Chapter |

| 16 - | Fuel pressure regulator |

| 17 - | Throttle valve module -J338- |

| 18 - | Intake manifold |

| q | With intake air temperature sender -G42- |

| 19 - | Crankcase breather |

| 20 - | Non-return valve |

| q | Installation position: arrow points direction of flow |

| 21 - | Turbocharger air recirculation valve -N249- |

| q | Fitting location → Fig. |

| q | Checking → Chapter |

| 22 - | Secondary air inlet valve -N112- |

| q | Checking → Chapter |

| 23 - | Secondary air pump motor -V101- |

| 24 - | Non-return valve |

| q | Between activated charcoal filter and intake manifold |

| q | Installation position: arrow points direction of flow |

| 25 - | Charge air cooler |

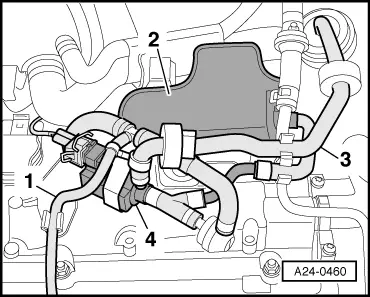

| Vehicles with engine code AMK, BAM |

| 1 - | From fuel tank |

| 2 - | Activated charcoal filter |

| q | With activated charcoal filter system solenoid valve 1 -N80- |

| 3 - | Non-return valve |

| q | Between activated charcoal filter and intake pipe upstream of turbocharger |

| q | Installation position: arrow points direction of flow |

| 4 - | Turbocharger |

| q | Checking charge pressure → Chapter |

| 5 - | Vacuum unit for charge pressure control |

| 6 - | Mechanical air recirculation valve |

| q | Checking → Chapter |

| 7 - | Brake servo |

| 8 - | Non-return valve |

| q | Between brake servo and intake manifold |

| q | Installation position: arrow points direction of flow |

| 9 - | Charge pressure control solenoid valve -N75- |

| q | Checking → Chapter |

| 10 - | Air mass meter -G70- |

| 11 - | Air cleaner |

| 12 - | Pressure control valve for crankcase breather system |

| 13 - | Vacuum reservoir |

| q | Bolted to cylinder head cover |

| 14 - | Charge air cooler |

| q | With charge pressure sender -G31- |

| q | Checking charge pressure sender -G31- → Chapter |

| 15 - | Fuel pressure regulator |

| 16 - | Throttle valve module -J338- |

| 17 - | Intake manifold |

| q | With intake air temperature sender -G42- |

| 18 - | Crankcase breather |

| 19 - | Non-return valve |

| q | Installation position: arrow points direction of flow |

| 20 - | Turbocharger air recirculation valve -N249- |

| q | Fitting location → Fig. |

| q | Checking → Chapter |

| 21 - | Non-return valve |

| q | Between activated charcoal filter and intake manifold |

| q | Installation position: arrow points direction of flow |

| 22 - | Charge air cooler |