| –

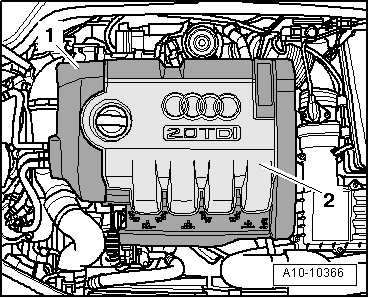

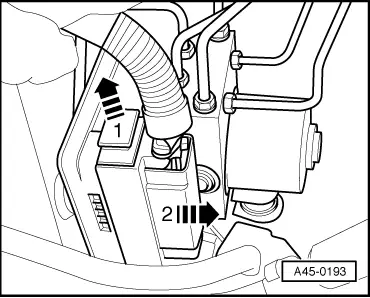

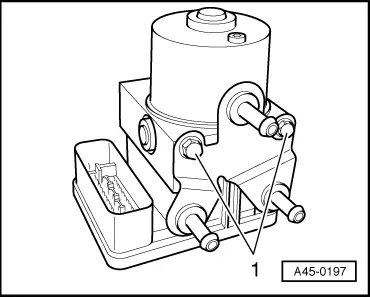

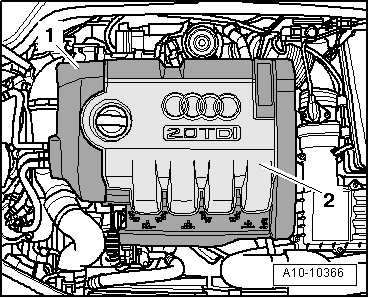

| Install engine cover panel -1 and 2-. |

| –

| If a new control unit has been fitted, it must be encoded. |

| To do so, use the vehicle diagnosis, testing and information system -VAS 5051 x - or -VAS 5052-. |

| –

| Connect vehicle diagnosis, testing and information system and select „function/component“ for function test → Chapter. |

| –

| „01 - Self-diagnosis compatible systems“ |

| –

| „J104 - Control unit for ABS/TCS/ESP Mark 60“ |

| –

| „J104 - Control unit for ABS/TCS/ESP, Functions“ |

| –

| „J104 - Encoding control unit“ |

| –

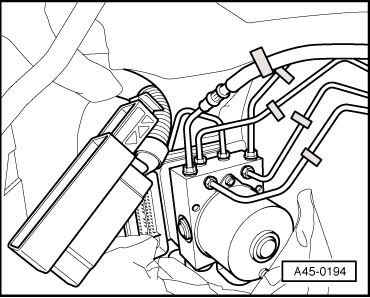

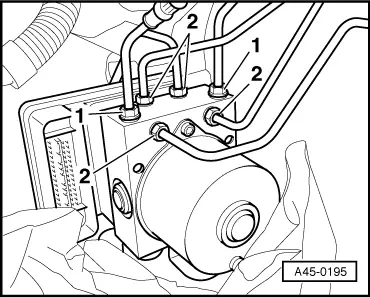

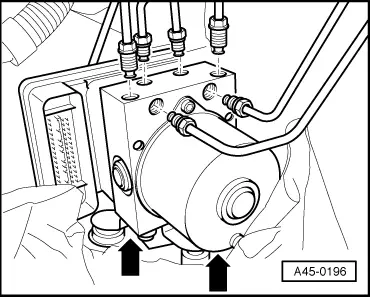

| Perform final control diagnosis after attaching brake lines to hydraulic unit. Vehicle diagnosis, testing and information system -VAS 5051 x - or -VAS 5052- |

Note | t

| If the ABS control unit (with ESP) -J104- is renewed, the following senders must be calibrated: |

| t

| Steering angle sender -G85- |

| t

| Lateral acceleration sender -G200- |

| t

| Brake pressure sender 1 -G201- |

| t

| Longitudinal acceleration sender -G251- (only four-wheel drive vehicles) |

| t

| From model year 2009 onwards, steering angle and brake pressure are also measured by the ABS control unit (with ESP) -J104-; these values must then be calibrated. |

| t

| ESP road test and system test must then be carried out. |

| To do so, use the vehicle diagnosis, testing and information system -VAS 5051 x - or -VAS 5052-. |

| –

| Connect -VAS 5051 x - or -VAS 5052- and select „function/component“ for function test → Chapter. |

| –

| „01 - Self-diagnosis compatible systems“ |

| –

| „J104 - Control unit for ABS/TCS/ESP Mark 60“ |

| –

| „J104 - Control unit for ABS/TCS/ESP, Functions“ |

| On vehicles with Mark 60EC system |

| If the ABS control unit -J104- is renewed on vehicles with Mark 60EC system, an additional basic setting must be performed for the inlet valves and separating valves → Chapter. |

| To do so, use the vehicle diagnosis, testing and information system -VAS 5051 x - or -VAS 5052-. |

Note | Final control diagnosis can be used to establish whether line connections have been interchanged. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

WARNING

WARNING