| t

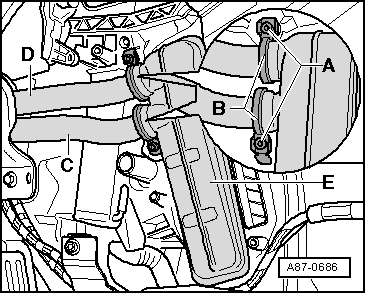

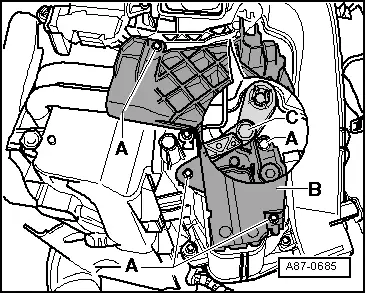

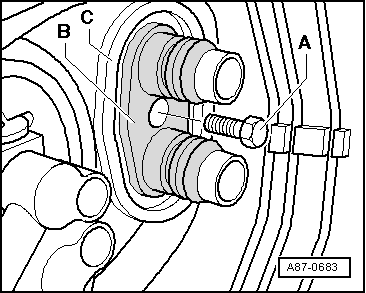

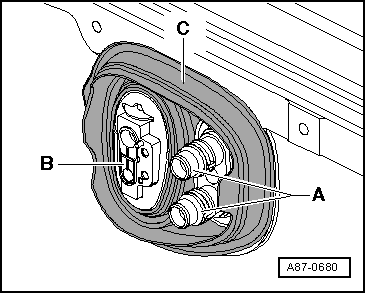

| There are different versions of the cover -B- (for vehicles without or with electric supplementary heater). |

| t

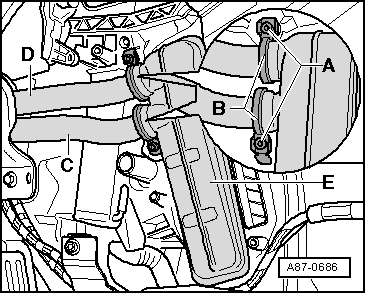

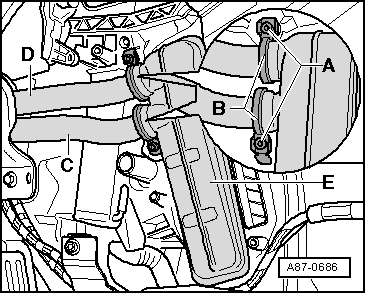

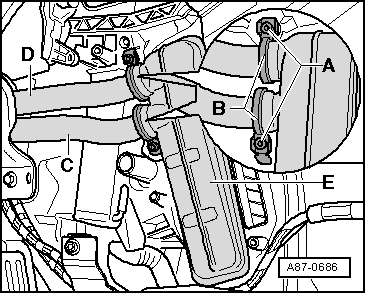

| If the lever -C- (to the left temperature flap) is positioned such that the upper bolt -A- is not accessible, switch on the ignition and select a different temperature setting (e.g. on the operating and display unit, Climatronic control unit -J255- the setting „Hi“ for the left side / on the air conditioner controls, air conditioning system control unit -J301-, the setting „Rotary temperature switch on warm stop“). |

| –

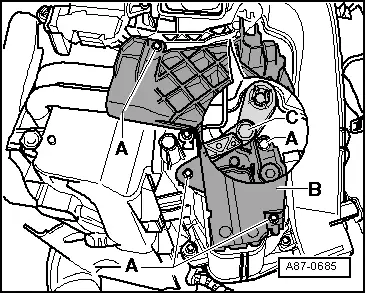

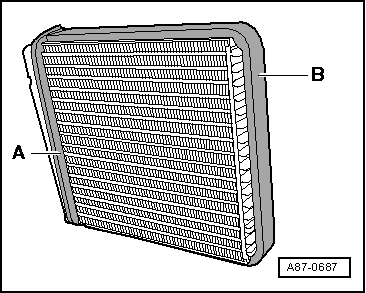

| Protect the floor covering in the area beneath the heat exchanger with impermeable sheeting and absorbent paper. |

|

|

|

Note

Note

Note

Note

Note

Note