| t

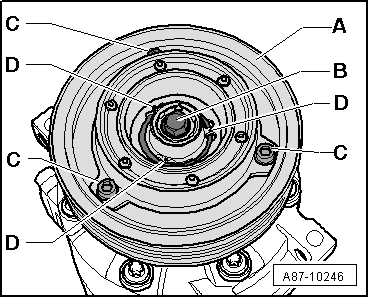

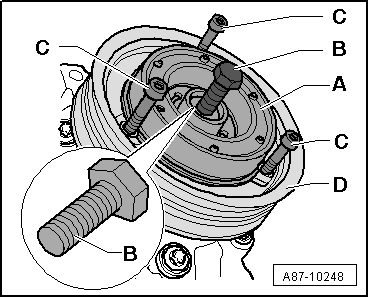

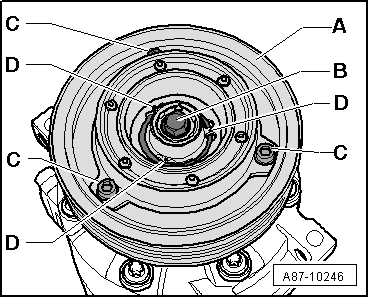

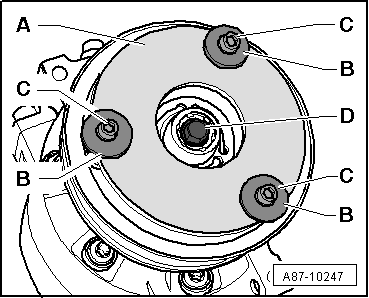

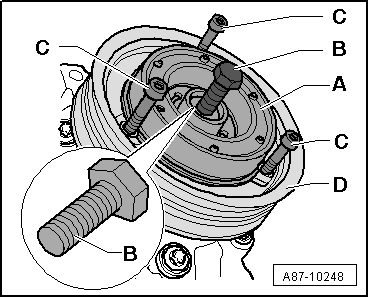

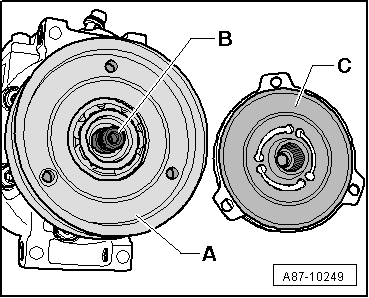

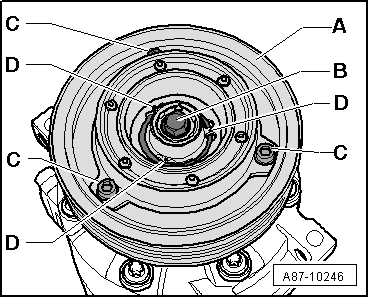

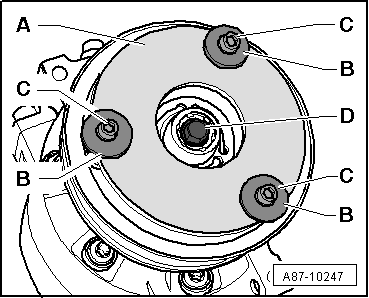

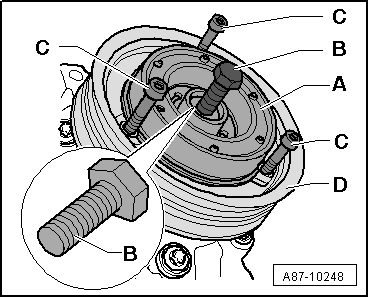

| If the drive plate -A- is bonded to the air conditioner compressor shaft, insert three long bolts -C- through the holes of the drive plate -A- into the pulley -D- and then use a commercially available bolt -B- (bolt with M8 thread, flat at front, strength class at least 10.9) to press off the drive plate -A-. When doing so, hold the pulley -D- in position using a commercially available strap wrench (with fabric strap). |

| t

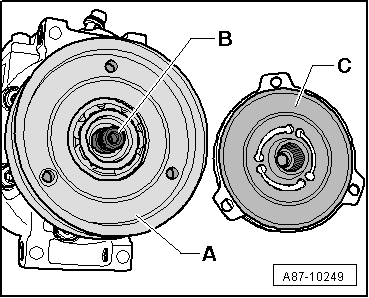

| If the drive plate -A- has already been replaced as part of service work and bonded on using the sealant D 154 102 A1, it may be so firmly attached to the air conditioner compressor shaft that it can no longer be pressed off. In this case the entire compressor must be replaced. |

| –

| If the pulley is to be replaced, remove the circlip and detach the pulley → Chapter. |

| –

| Clean and check the splines of the air conditioner compressor shaft. Replace the air conditioner compressor if the splines show signs of wear. |

Caution | Do not use compressed air when cleaning. Blowing out could cause dirt particles to settle on and damage the air conditioner compressor shaft seal. |

|

Caution | Do not use compressed air when cleaning. Blowing out could cause dirt particles to settle on and damage the air conditioner compressor shaft seal. |

|

|

|

|

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note