A3 Mk2

Note

Note

|

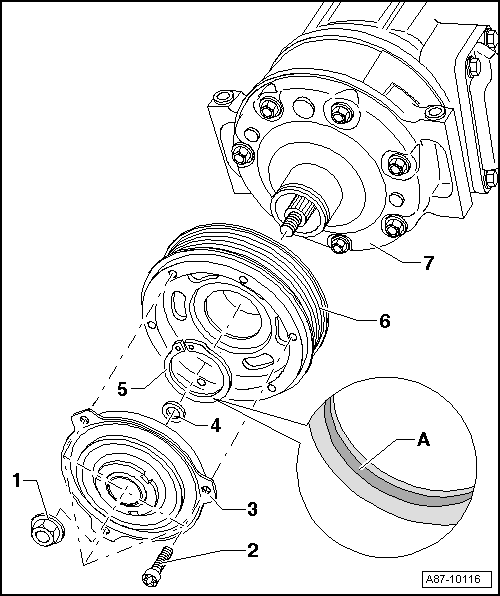

| 1 - | Hexagon nut |

| q | To unfasten and tighten the hexagon nut, hold the pulley in position with a commercially available strap wrench (with fabric strap). |

| q | Before screwing on, remove the old locking fluid from the hexagon nut thread and the thread of the air conditioner compressor shaft. |

| q | Apply locking fluid when fitting the hexagon nut (e.g. D 000 600 A2) → Electronic parts catalogue. |

| q | Tightening torque 25 Nm |

| 2 - | Bolt |

| q | To slacken off and tighten the bolts, hold the pulley in position with a commercially available strap wrench (with fabric strap). |

| q | Before screwing in, remove the old locking fluid from the bolt threads and the threads of the pulley. |

| q | Apply locking fluid when fitting the bolts (e.g. D 000 600 A2) → Electronic parts catalogue. |

| q | Tightening torque 4.5 Nm |

| 3 - | Drive plate |

| q | With overload safeguard; tripped in the event of excessive torque (e.g. stiff air conditioner compressor) and the pulley just free-wheels without driving the air conditioner compressor. |

| q | With rubber element for decoupling the pulley from the air conditioner compressor drive shaft and for damping vibration and noise. |

| 4 - | Washer |

| 5 - | Circlip |

| q | Replace |

| q | Fit in correct position with the bevelled side -A- facing away from the air conditioner compressor (flat side towards compressor). |

| q | On fitting the circlip, take care not to bend it open more than necessary. |

| 6 - | Pulley |

| q | Clean the air conditioner compressor flange before fitting the pulley. |

| 7 - | Air conditioner compressor |

| q | Different models may be fitted depending on the engine version and country version of the vehicle → Electronic parts catalogue. |

| q | Clean the air conditioner compressor flange before fitting the pulley. |

Note

Note

|

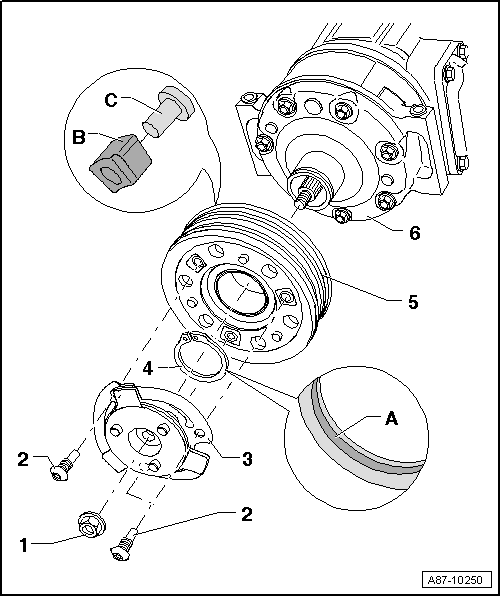

| 1 - | Hexagon nut |

Note

Note| A plastic cap is additionally fitted to protect the thread of the compressor shaft (this cap is not shown in the illustration). |

| q | To unfasten and tighten the hexagon nut, hold the pulley in position with a commercially available strap wrench (with fabric strap). |

| q | Before screwing on, remove the old locking fluid from the hexagon nut thread and the thread of the air conditioner compressor shaft. |

| q | Apply locking fluid when fitting the hexagon nut / bolt (e.g. D 000 600 A2) → Electronic parts catalogue. |

| q | Tightening torque for hexagon nut 25 Nm |

| 2 - | Bolt |

| q | To slacken off and tighten the bolts, hold the pulley in position with a commercially available strap wrench (with fabric strap). |

| q | Tightening torque 12 Nm |

| q | Before screwing in, remove the old locking fluid from the bolt threads and the threads of the pulley. |

| q | Apply locking fluid when fitting the bolts (e.g. D 000 600 A2) → Electronic parts catalogue. |

| 3 - | Drive plate |

| q | With overload safeguard (attachment of spring elements); this is tripped in the event of excessive torque (e.g. stiff air conditioner compressor) and the pulley just free-wheels without driving the air conditioner compressor. |

| q | The spring elements of the drive plate dampen vibrations and reduce noise. |

| 4 - | Circlip |

| q | Replace |

| q | Fit in correct position with the bevelled side -A- facing away from the air conditioner compressor (flat side towards compressor). |

| q | On fitting the circlip, take care not to bend it open more than necessary. |

| 5 - | Pulley |

| q | Clean the air conditioner compressor flange before fitting the pulley. |

| q | With rubber elements -B- and threaded plates -C- for isolating the pulley from the air conditioner compressor drive shaft (the rubber elements dampen vibrations and reduce noise). |

Note

Note| Depending on the version, the threaded plates -C- may also be linked by way of a ring. |

| 6 - | Air conditioner compressor |

| q | Different models may be fitted depending on the engine version and country version of the vehicle → Electronic parts catalogue. |

| q | Clean the air conditioner compressor flange before fitting the pulley. |

|

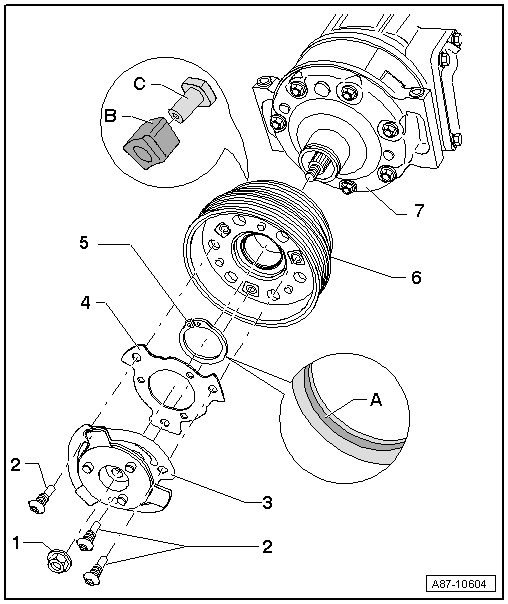

| 1 - | Hexagon nut |

Note

Note| A plastic cap may additionally be fitted to protect the thread of the compressor shaft (this cap is not shown in the illustration). |

| q | To unfasten and tighten the hexagon nut, hold the pulley in position with a commercially available strap wrench (with fabric strap). |

| q | Before screwing on, remove the old locking fluid from the hexagon nut thread and the thread of the air conditioner compressor shaft. |

| q | Apply locking fluid when fitting the hexagon nut (e.g. D 000 600 A2) → Electronic parts catalogue. |

| q | Tightening torque for hexagon nut 25 Nm |

| 2 - | Bolt |

| q | To slacken off and tighten the bolts, hold the pulley in position with a commercially available strap wrench (with fabric strap). |

| q | Tightening torque 12 Nm |

| q | Before screwing in, remove the old locking fluid from the bolt threads and the threads of the pulley. |

| q | Apply locking fluid when fitting the bolts (e.g. D 000 600 A2) → Electronic parts catalogue. |

| 3 - | Drive plate |

| q | With overload safeguard (attachment of spring elements); this is tripped in the event of excessive torque (e.g. stiff air conditioner compressor) and the pulley just free-wheels without driving the air conditioner compressor. |

| q | The spring elements of the drive plate dampen vibrations and reduce noise. |

| 4 - | Spacer |

| 5 - | Circlip |

| q | Replace |

| q | Fit in correct position with the bevelled side -A- facing away from the air conditioner compressor (flat side towards compressor) |

| q | On fitting the circlip, take care not to bend it open more than necessary. |

| 6 - | Double-belt pulley |

| q | Clean the air conditioner compressor flange before fitting the pulley. |

| q | With rubber elements -B- and threaded plates -C- for isolating the pulley from the air conditioner compressor drive shaft (the rubber elements dampen vibrations and reduce noise). |

Note

Note| t | Depending on the version, the threaded plates -C- may also be linked by way of a ring. |

| t | On vehicles with a 5-cyl. engine 2 belts are routed over the pulley. |

| 7 - | Air conditioner compressor |

| q | Different models may be fitted depending on the engine version and country version of the vehicle → Electronic parts catalogue. |

| q | Clean the air conditioner compressor flange before fitting the pulley. |