| t

| Loosen the nuts and bolts in reverse sequence to the specified tightening sequence. |

| t

| Nuts and bolts which secure covers and housings should be loosened and tightened in diagonal sequence and in stages if no tightening sequence is specified. |

| t

| Loosen and tighten particularly sensitive parts in diagonal sequence and in stages, taking care to keep them straight. |

| t

| Always renew self-locking nuts and bolts. |

| t

| The tightening torques stated apply to non-oiled nuts and bolts. |

| t

| Use a wire brush to clean the threads of bolts which are secured with locking fluid. Then apply locking fluid -AMV 185 101 A1- to bolt threads before installing. |

| t

| Threaded holes which take self-locking bolts or bolts coated with locking fluid must be cleaned (using a thread tap or similar). Otherwise there is a danger of the bolts shearing off the next time they are removed. |

| t

| For all threaded connections, ensure that (where applicable) the contact surfaces and the nuts and bolts are not coated with wax until after assembly is completed. |

| t

| Lubricate all bearings in gearbox housing with gear oil before installing. |

| t

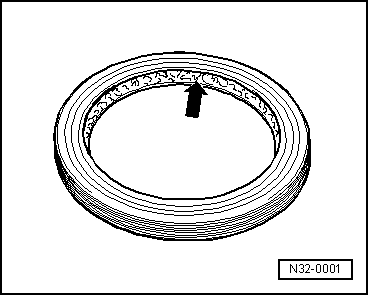

| Use inductive heater -VAS 6414- to heat inner races of tapered roller bearings to approx. 100°C before installing. Press home onto stop when installing so there is no axial clearance. |

| t

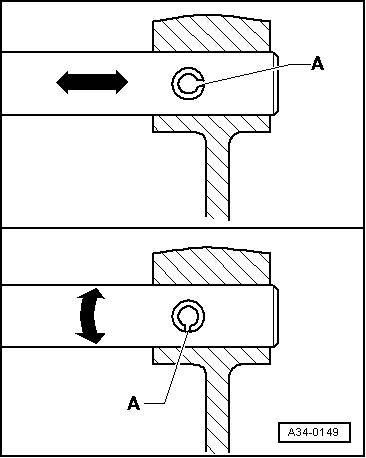

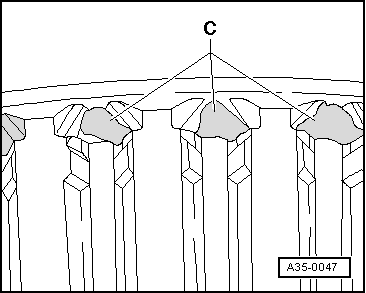

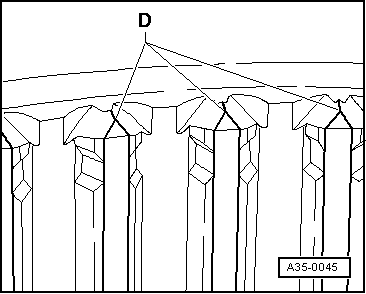

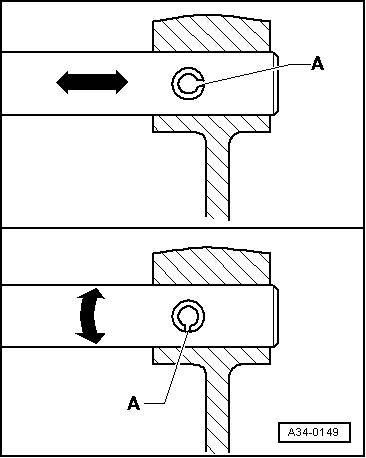

| Do not interchange the outer or inner races of bearings of the same size (the bearings are paired). |

| t

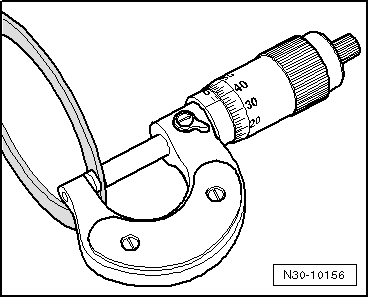

| If required, renew the tapered roller bearings on one shaft together and use new bearings from a single manufacturer. |

| t

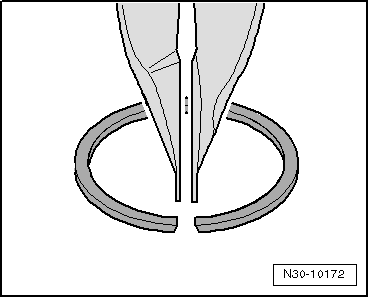

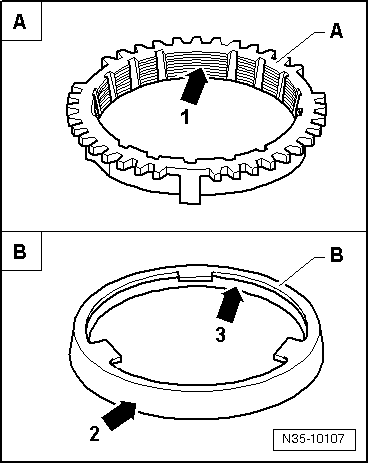

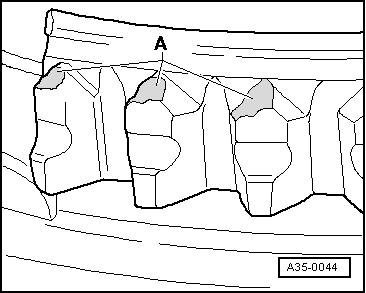

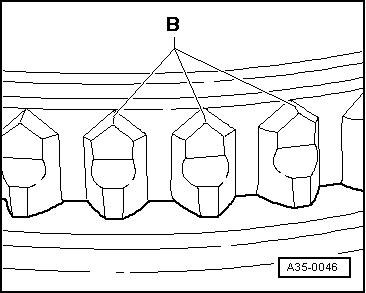

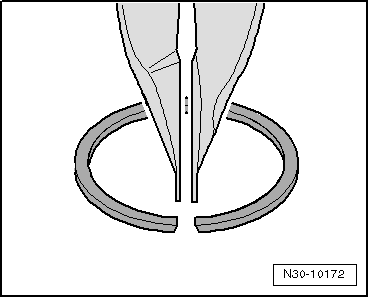

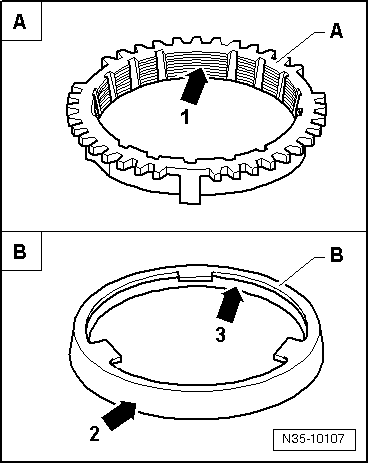

| Install needle bearings, ball sleeves and roller bearings so the lettering (side with thicker metal) faces towards the installing tool. |

|

|

|