A3 Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

| Component | Nm | |

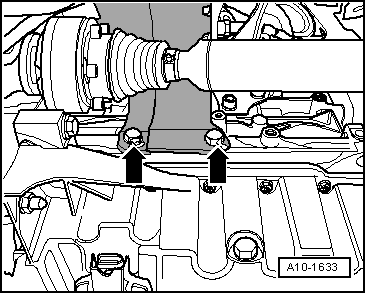

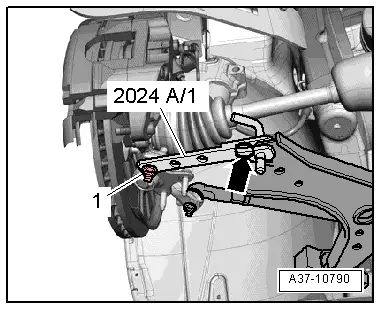

| Heat shield for drive shaft to cylinder block | 25 | |

WARNING

WARNING