| –

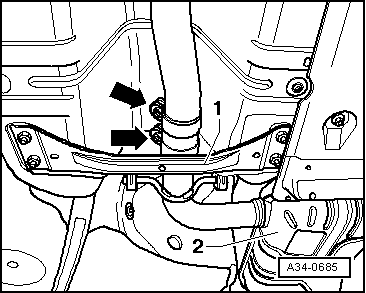

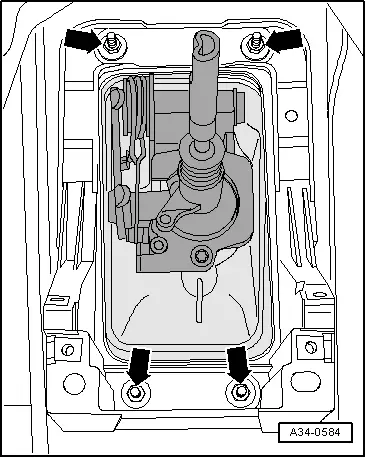

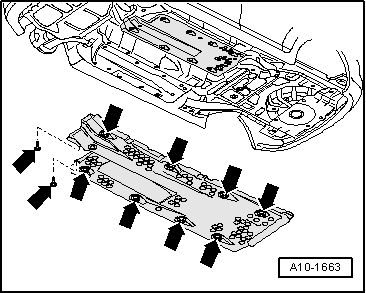

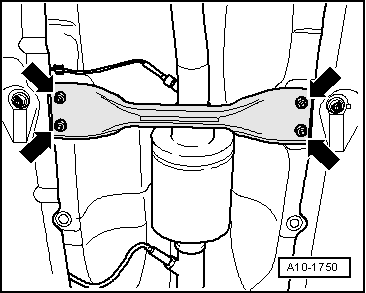

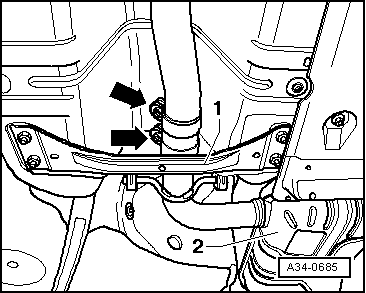

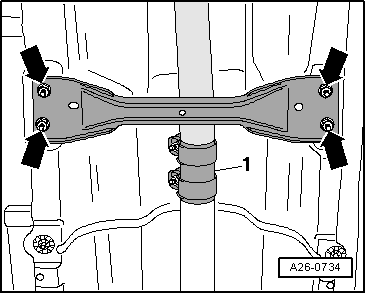

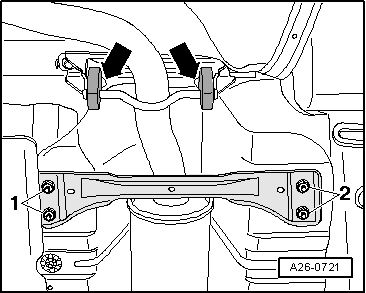

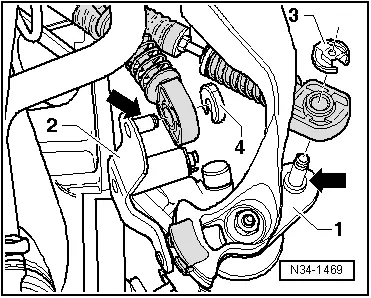

| Remove rear tunnel cross-piece -1-. |

| –

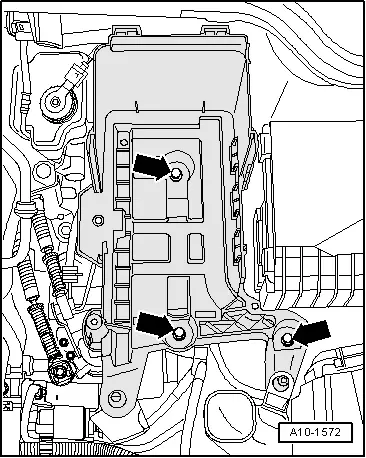

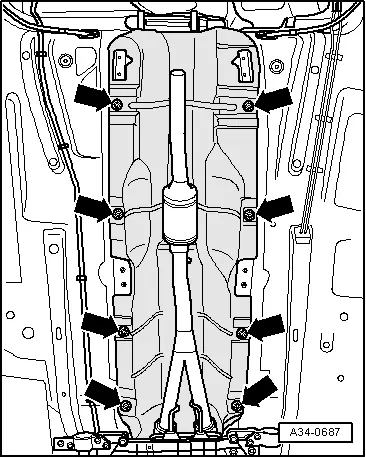

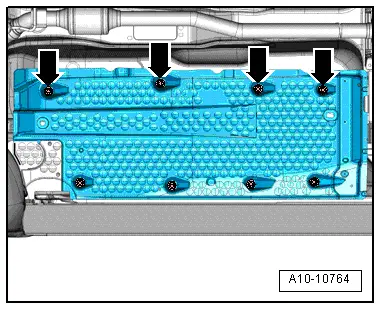

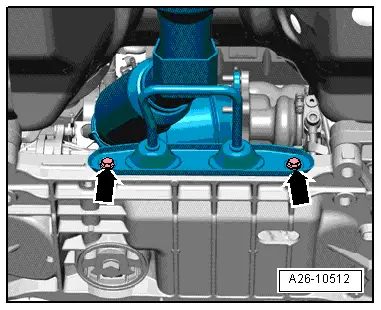

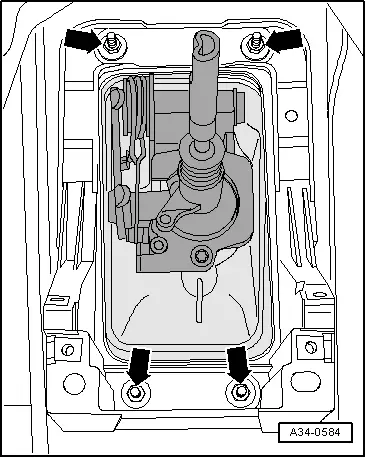

| Take up weight of front section of exhaust system at catalytic converter using engine/gearbox jack -V.A.G 1383 A-. |

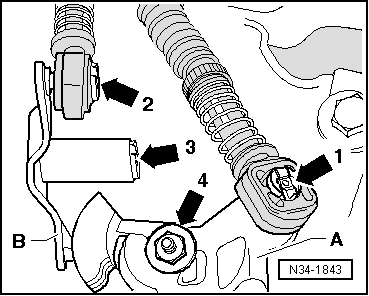

Note | To prevent damage, the flexible couplings in the front exhaust pipe must not be bent further than 10°. |

| –

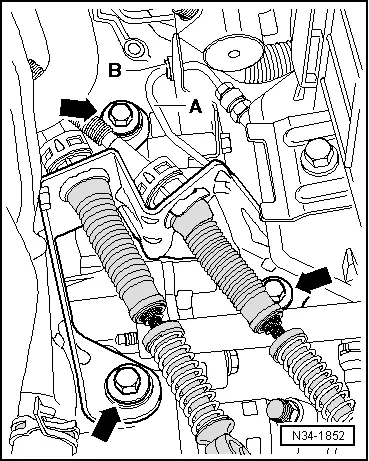

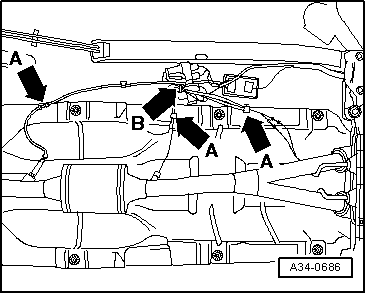

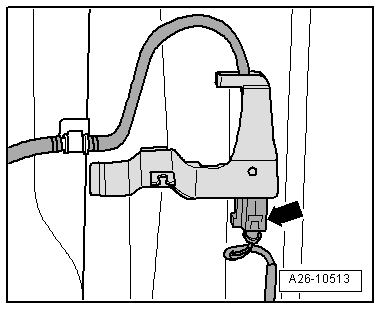

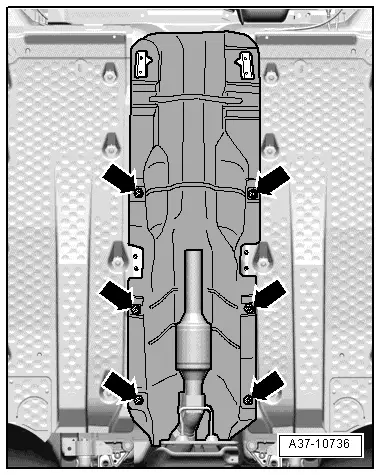

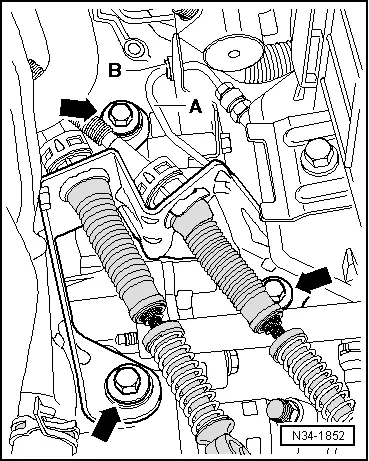

| Disconnect exhaust system at clamp -arrows-. |

Note | A second mechanic is required for removing the rear section of the exhaust system. |

| –

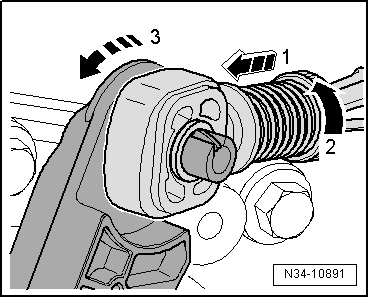

| Detach rear silencer -2- at rubber mountings and remove rear section of exhaust system. |

| –

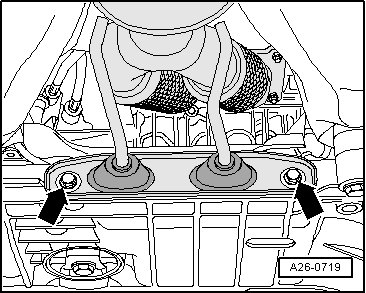

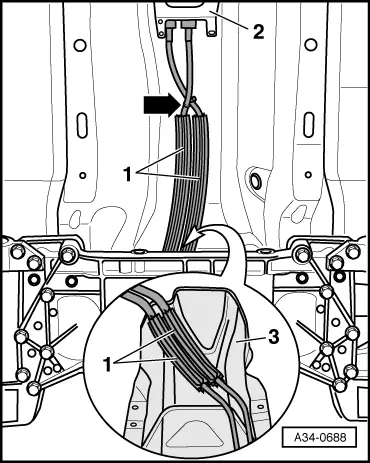

| Lower front section of exhaust system slightly using engine and gearbox jack -V.A.G 1383 A- (not more than 10°). Make sure there is sufficient clearance for Lambda probe wiring. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING