| –

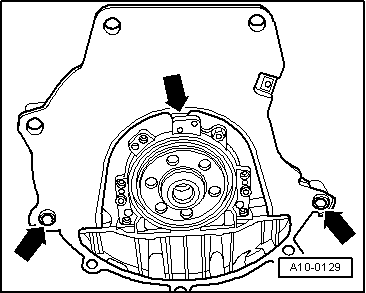

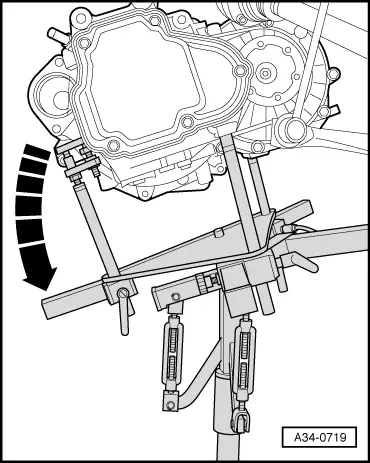

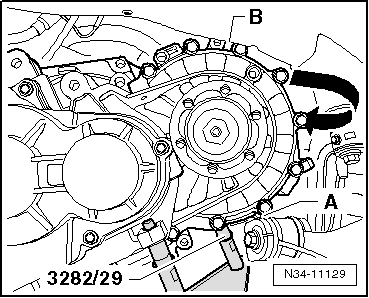

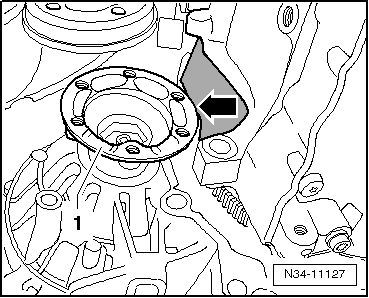

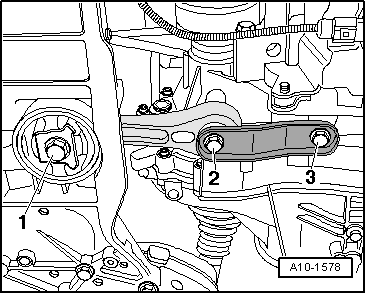

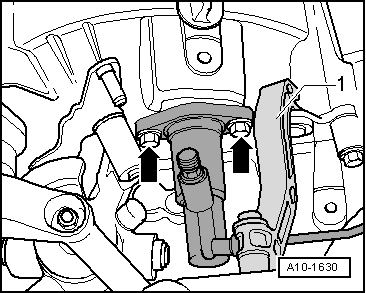

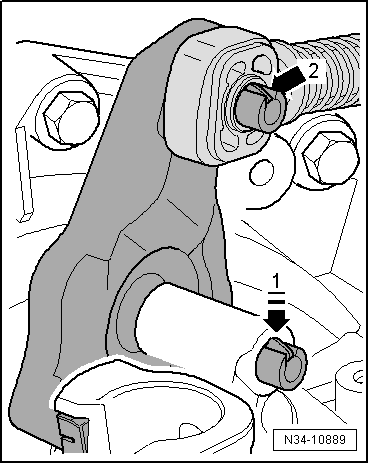

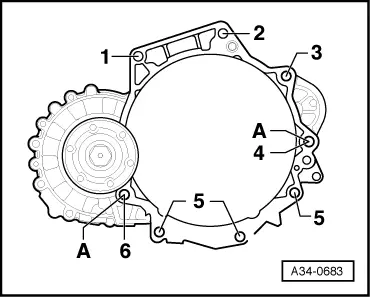

| Align engine/gearbox in installation position. To do so, raise engine/gearbox until gearbox bracket makes full contact with gearbox mounting. |

Caution | The threads in the gearbox bracket can be damaged if the bolts are not inserted straight. |

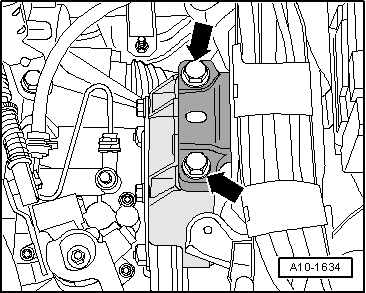

| Before fitting the bolts -arrows-, the gearbox bracket and the support arm of the gearbox mounting must be aligned absolutely parallel. If necessary, press rear part of gearbox up with engine and gearbox jack. |

|

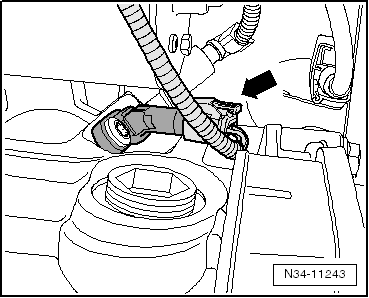

| –

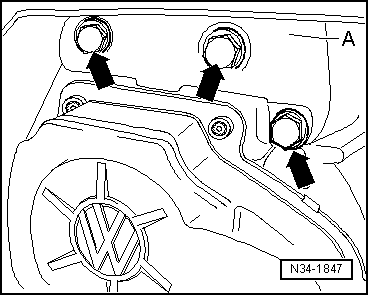

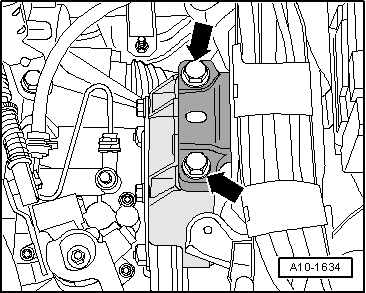

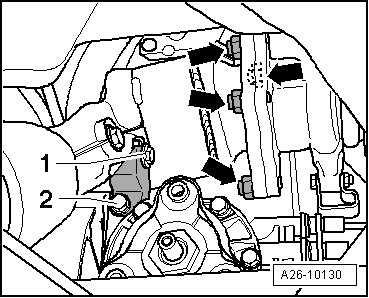

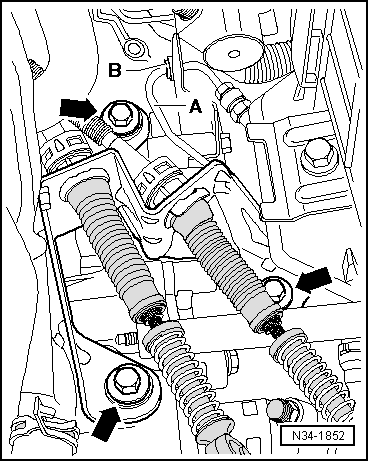

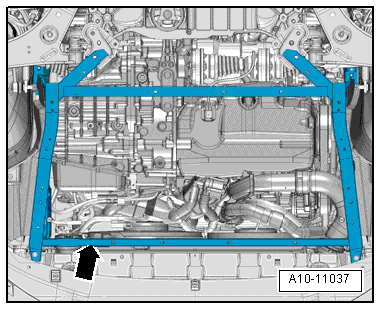

| Use new bolts -arrows- to secure gearbox mounting to gearbox bracket. Tightening torque → Item |

WARNING | Do not remove support bracket -10 - 222 A- until all bolts securing the left-hand engine/gearbox mounting have been tightened to the specified torque. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING