| –

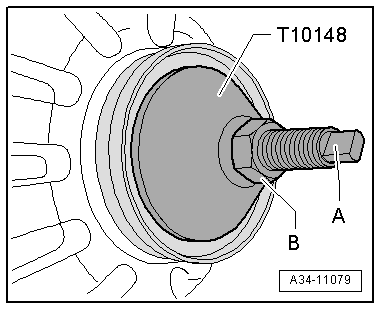

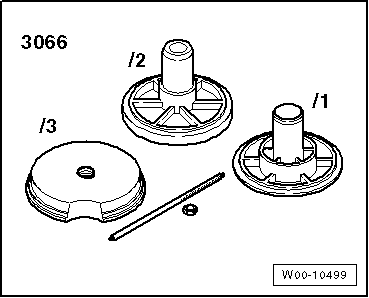

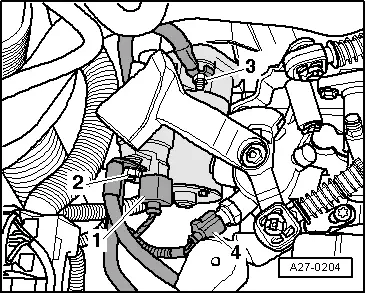

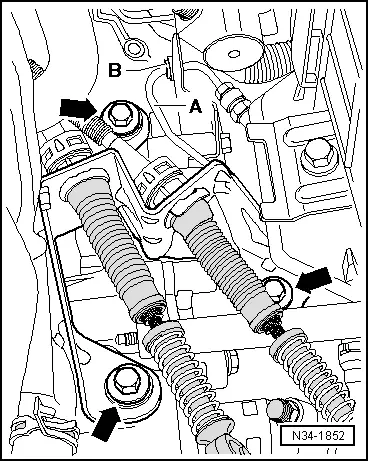

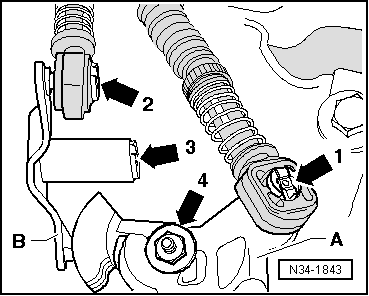

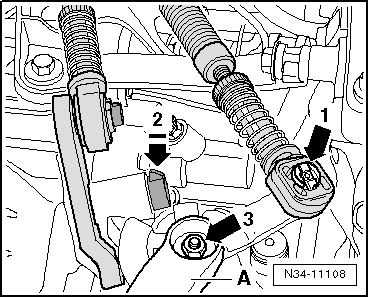

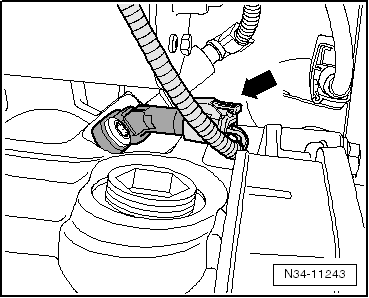

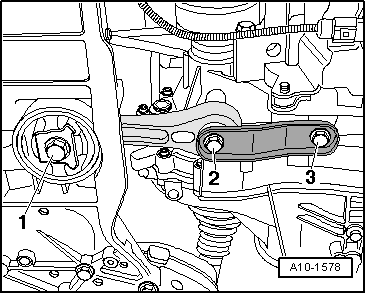

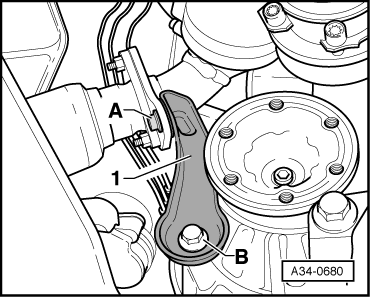

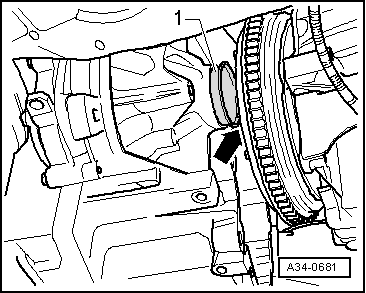

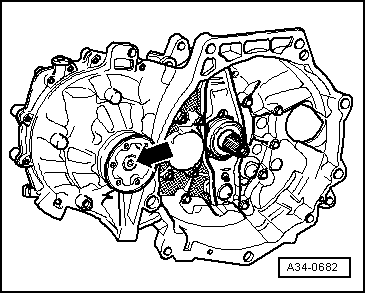

| Screw spindle -A- of assembly device -3066- into threaded piece in differential. |

| –

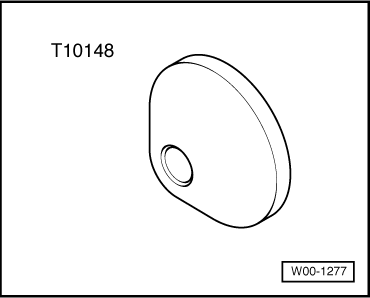

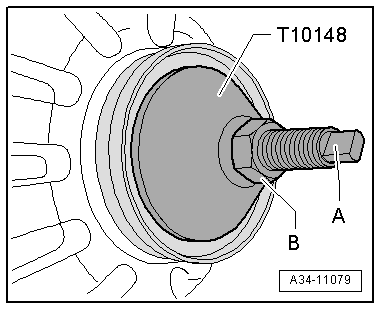

| Insert thrust piece -T10148- and secure with nut -B-. |

Note | t

| The thrust piece -T10148- serves to protect the oil seal (right-side) and the gearbox from dirt. |

| t

| Instead of using the spindle -A-, an M8 x 105 mm bolt can also be screwed hand-tight into the threaded piece in the differential. |

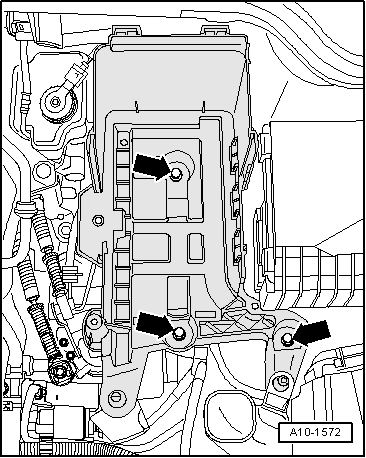

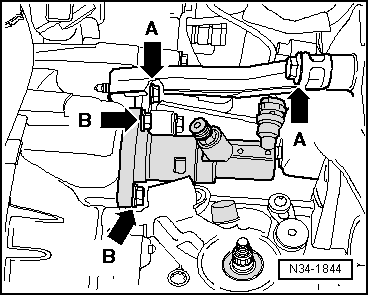

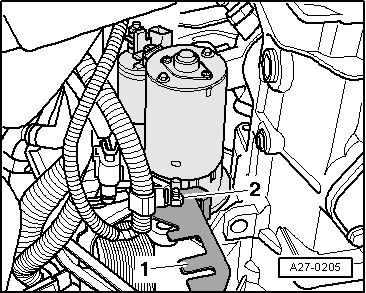

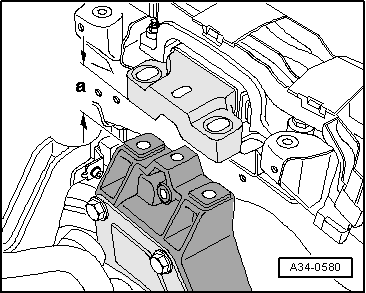

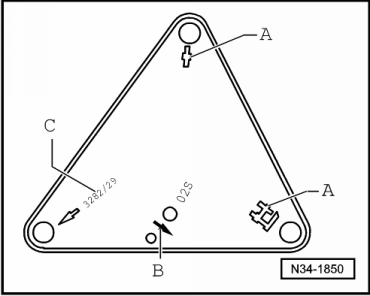

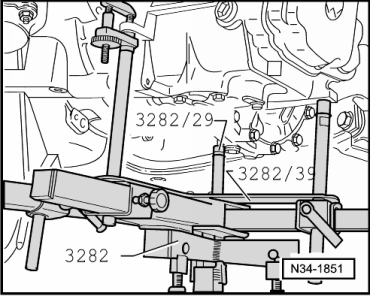

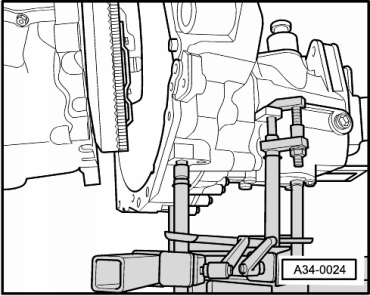

| To remove gearbox „02S“, set up gearbox support -3282- with adjustment plate -3282/39-. |

| –

| Insert gearbox support -3282- in engine and gearbox jack -V.A.G 1383 A-. |

| –

| Align arms of gearbox support according to holes in adjustment plate. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING