| –

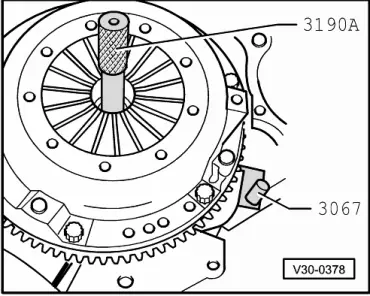

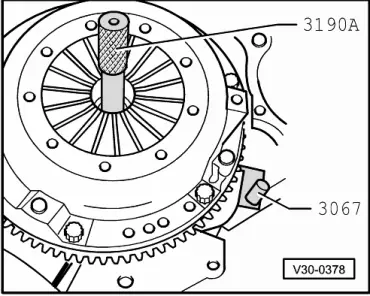

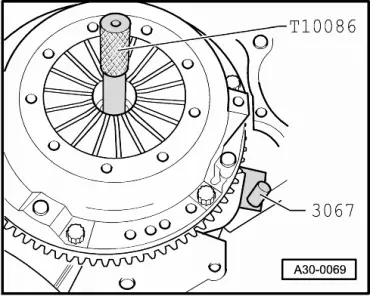

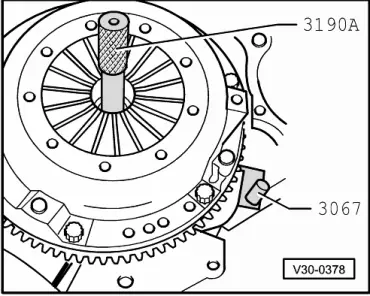

| Apply counter-hold tool -3067- in order to loosen bolts. |

| –

| Loosen bolts in small steps and in diagonal sequence. |

Note | Centring mandrel -3190 A- can be disregarded. |

| –

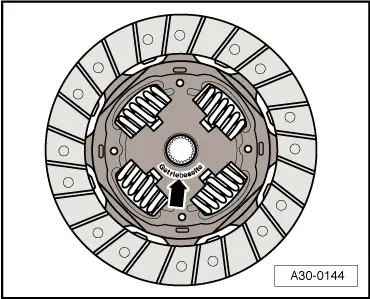

| Take off pressure plate and clutch plate. |

| Installation is carried out in reverse sequence; note the following: |

Note | t

| Renew clutch plate and pressure plate if riveted joints are damaged or loose. |

| t

| If the clutch has burnt out, thoroughly clean the clutch housing, flywheel and parts of the engine facing the gearbox in order to reduce the smell of burnt linings. |

| t

| Clean input shaft splines and (in the case of a used clutch plate) the hub splines. Remove corrosion and apply only a very thin coating of grease -G 000 100- to the splines. Then move clutch plate backwards and forwards on input shaft until hub moves freely on shaft. It is important to remove excess grease. |

| t

| Pressure plates have an anti-corrosion coating and are greased. Only the contact surface may be cleaned, otherwise the service life of the clutch will be considerably reduced. |

| t

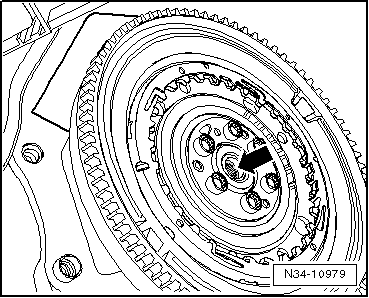

| Pressure plate contact surface and clutch plate lining must make full contact with flywheel. Only then insert bolts. |

| t

| Check that dowel sleeves for centralising engine/gearbox are in the cylinder block; install if necessary. |

| t

| If the dowel sleeves are not fitted, this will lead to gear-change problems, clutch malfunction and in some cases gearbox noise (gears will make rattling noises). |

|

|

|

Note

Note Note

Note