| Installation is carried out in reverse sequence; note the following: |

Note | t

| Renew seals, gaskets and self-locking bolts and nuts. |

| t

| Renew bolts which are tightened by turning through a specified angle. |

| t

| All cable ties which are released or cut open during removal must be fitted in the same position when installing. |

| t

| Clean input shaft splines and (in the case of used clutch plates) the hub splines. Remove corrosion and apply only a very thin coating of grease -G 000 100- to the splines. Then move clutch plate backwards and forwards on input shaft until hub moves freely on shaft. It is important to remove excess grease. |

| t

| It should be possible to push the clutch plate back and forth slightly on the input shaft. |

| t

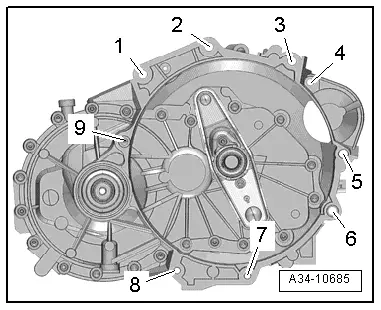

| If the dowel sleeves are not fitted, this will lead to gear-change problems, clutch malfunction and in some cases gearbox noise (gears will make rattling noises). |

|

|

|

Note

Note

Note

Note