| –

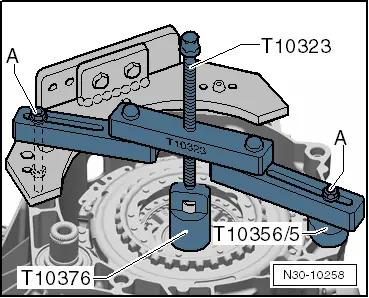

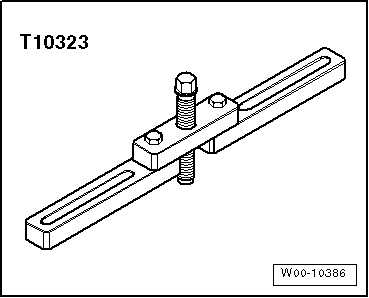

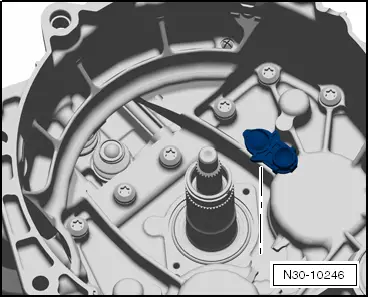

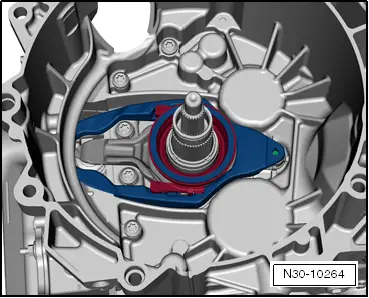

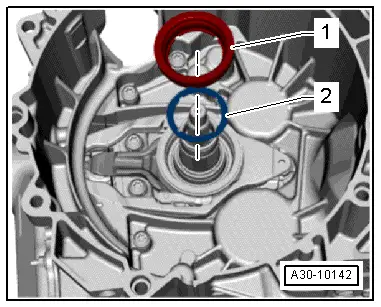

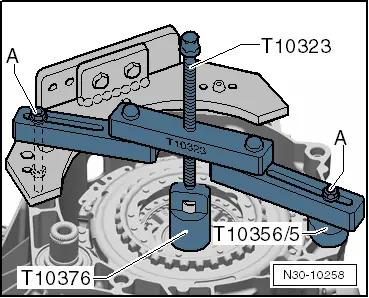

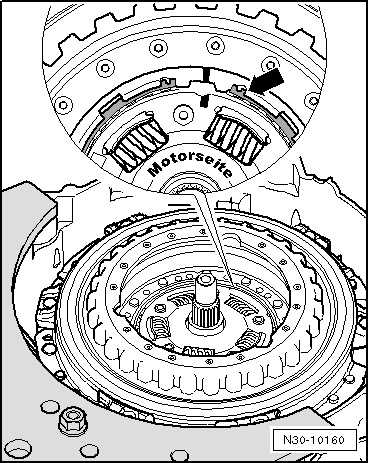

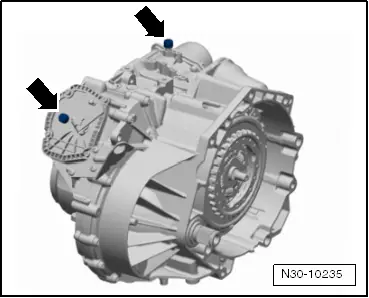

| Set up support bridge -T10323- so it is parallel to gearbox flange, as shown in illustration. |

| –

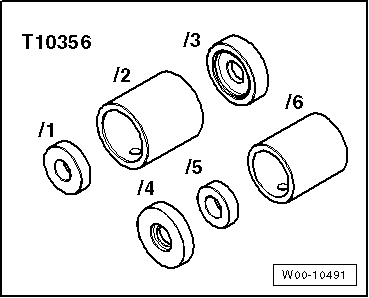

| If necessary, use e.g. -T10356/5- of assembly tool -T10356- as a spacer. |

| –

| Fit bolts -A- hand-tight. |

Note | Secure bolts -A- with nuts as required. |

| –

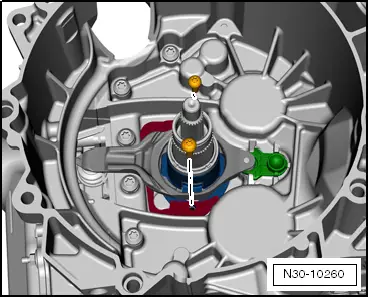

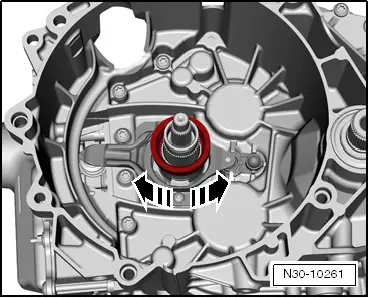

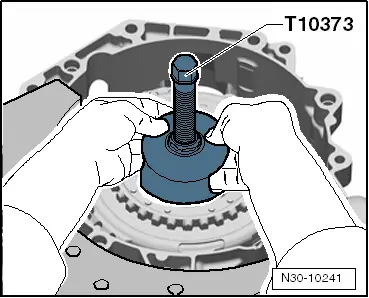

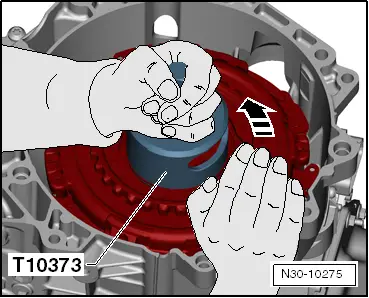

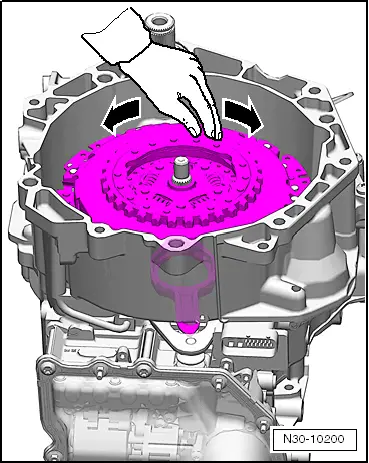

| Press on clutch as far as stop. |

Note | Place a hand on the clutch when pressing it on. You will be able to feel a slight grating or juddering movement. This indicates that the clutch is being pressed in to a press fit. You can also feel when the clutch reaches its stop and is fully seated. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

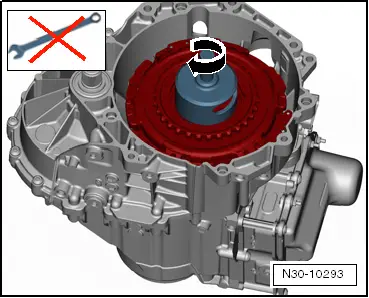

Caution

Caution