A3 Mk2

| Sump, oil pump - exploded view |

| 1 - | Oil level and oil temperature sender -G266- |

| q | Removing and installing → Chapter |

| 2 - | Seal |

| q | Renew |

| 3 - | Sump |

| q | Removing and installing → Chapter |

| q | Apply sealant when installing; refer to → Electronic parts catalogue |

| 4 - | Bolt |

| q | Renew |

| q | 14 Nm + 90° further |

| 5 - | Drive chain sprocket |

| q | For oil pump |

| q | Sprocket can only be fitted on oil pump shaft in one position. |

| q | Counterhold using counterhold tool -T10172- |

| 6 - | Bolt |

| q | Renew |

| q | 20 Nm + 90° further |

| 7 - | Cover |

| q | For chain sprocket |

| q | Clipped onto oil pump |

| 8 - | Drive chain |

| q | For oil pump |

| q | Before removing, mark running direction with paint |

| q | Check for wear |

| q | Removing and installing → Chapter |

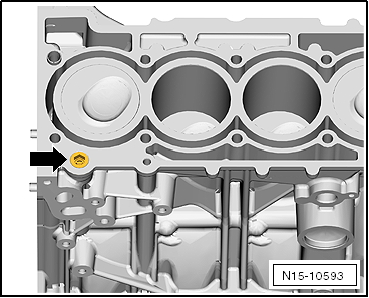

| 9 - | Dowel sleeves |

| 10 - | Chain sprocket |

| q | For drive chain for oil pump |

| q | On crankshaft |

| 11 - | Oil pump |

| q | With pressure relief valve |

| q | Removing and installing → Chapter |

| q | Before installing, check that the two dowel sleeves for centring oil pump/cylinder block are fitted |

| 12 - | O-ring |

| q | Renew |

| 13 - | Bolt |

| q | 8 Nm |

| 14 - | Suction pipe |

| q | Clean strainer if dirty |

| 15 - | Bolt |

| q | Renew |

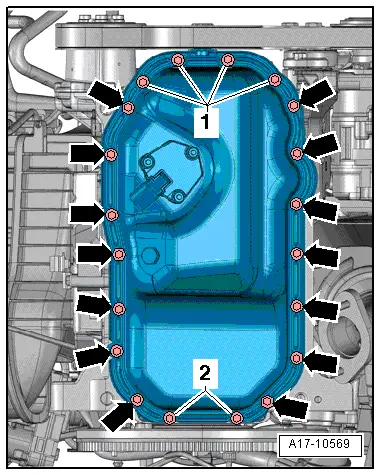

| q | Tightening torque and sequence → Fig. |

| q | When loosening and tightening the bolts on the gearbox end, use Allen key, long reach -T10058- |

| 16 - | Seal |

| q | Renew |

| 17 - | Oil drain plug |

| q | 30 Nm |

| 18 - | Nut |

| q | 9 Nm |

Note

Note

|

|

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -1, 2-, -arrows- | 8 Nm |

| 2. | -1, 2- | turn 45° further |

| 3. | -arrows- | turn 90° further |

|

|