A3 Mk2

| Removing and installing timing chain cover |

| Special tools and workshop equipment required |

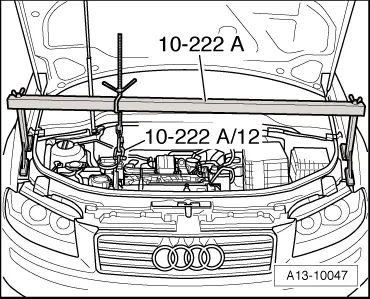

| t | Support bracket -10-222 A- |

| t | Allen key (long reach) -T10058- |

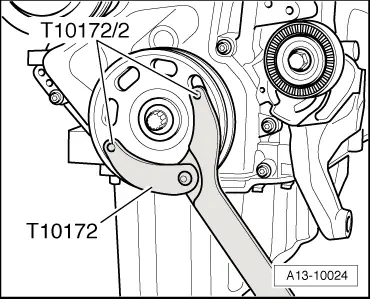

| t | Counterhold tool -T10172- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

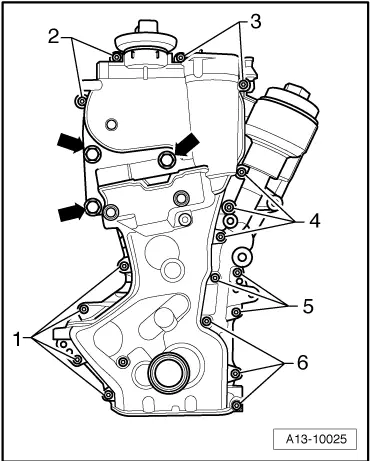

| Component | Nm | |||||

| Timing chain cover to | M6 | 10 | ||||

| cylinder block and cylinder head | M10 | 50 | ||||

| Engine lifting eye to timing chain cover | 20 | |||||

| Pressure control valve for crankcase breather system to timing chain cover | 10 | |||||

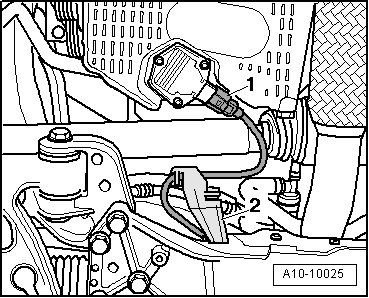

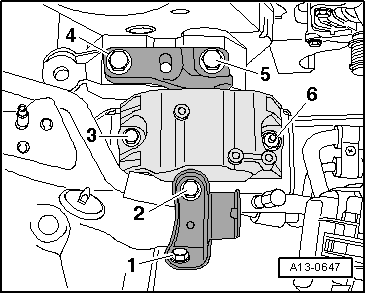

| Engine mounting to body | 50 | |||||

| Connecting bracket to engine mounting/body | 20 + 90° 1)2) | |||||

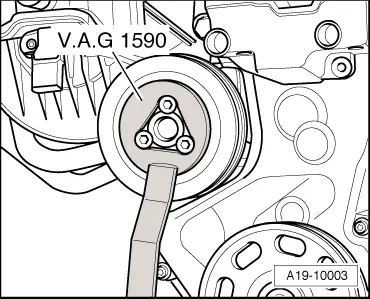

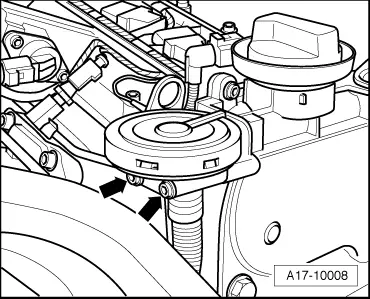

| Coolant pump pulley to coolant pump | 20 | |||||

| Idler roller to engine | 40 | |||||

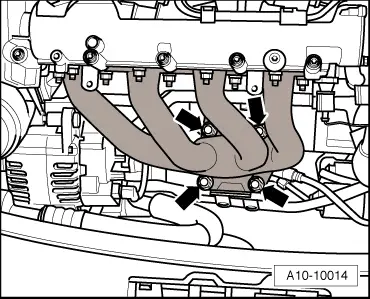

| Hot air collector plate to exhaust manifold | 10 | |||||

| ||||||

Caution

Caution WARNING

WARNING