| –

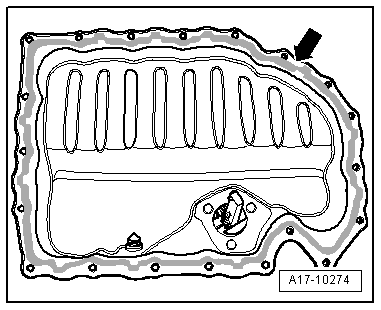

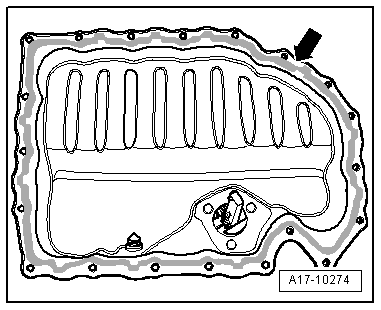

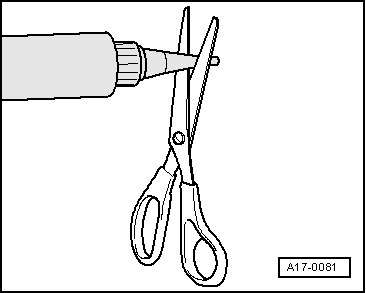

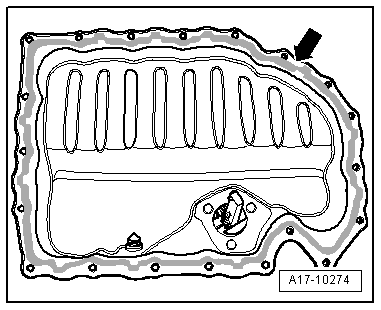

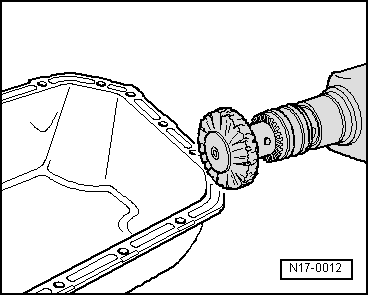

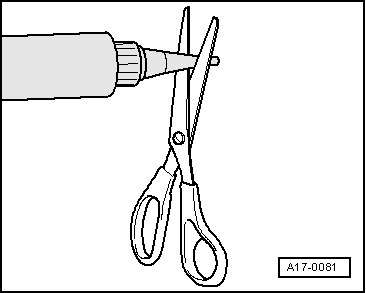

| Apply bead of silicone sealant onto clean sealing surface of sump (bottom section), as illustrated. |

Caution | Make sure lubrication system is not clogged by excess sealant. |

| The bead of sealant must not be thicker than specified. |

|

| t

| Thickness of sealant bead: 2 ... 3 mm |

Note | t

| The sump must be installed within 5 minutes after applying the silicone sealant. |

| t

| The bead of sealant must not be thicker than specified, otherwise excess sealant can enter the sump and obstruct the strainer in the oil intake pipe. |

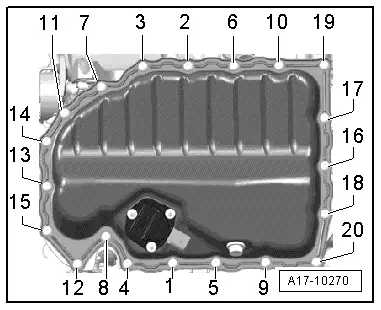

| –

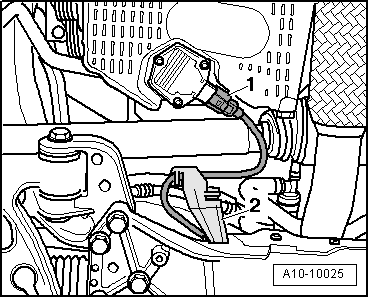

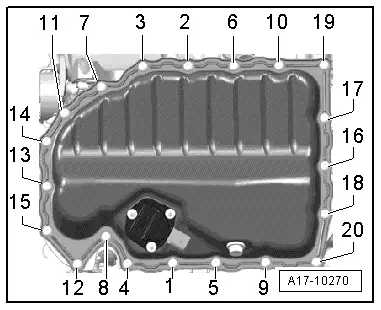

| Immediately fit sump (bottom section) and tighten bolts; tightening sequence → Fig.. |

Note | After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

| Further assembly is basically carried out in reverse order of dismantling. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note