A3 Mk2

| Removing and installing camshafts |

| Special tools and workshop equipment required |

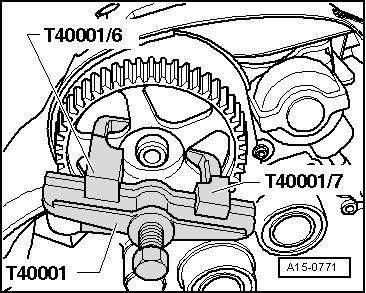

| t | Two-arm puller -T40001- |

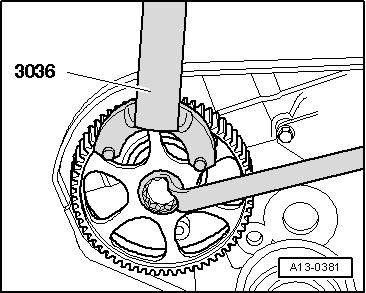

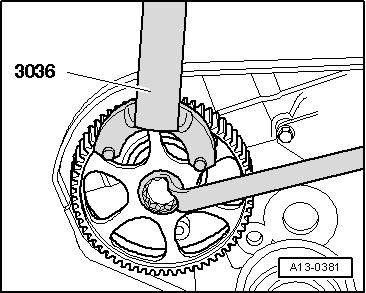

| t | Counterhold tool -3036- |

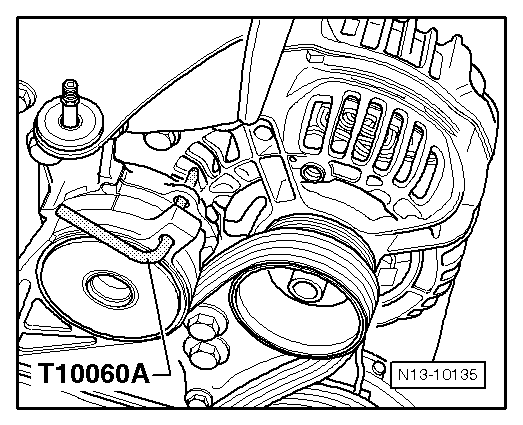

| t | Locking pin -T10060 A- |

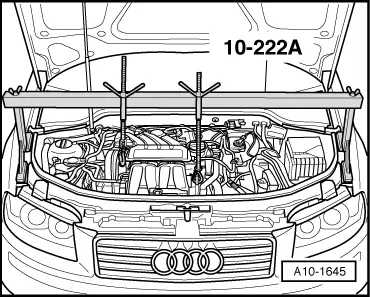

| t | Support bracket -10 - 222 A- |

| t | Thrust piece -3334- |

| t | Shackle -10 - 222 A /12- |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

WARNING

WARNING