| –

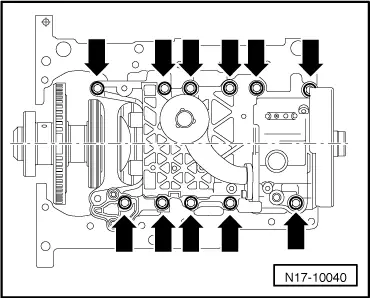

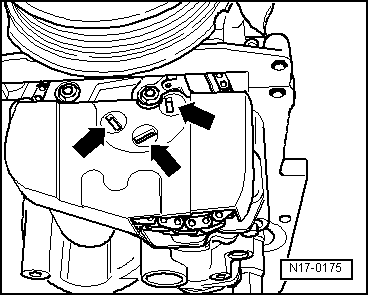

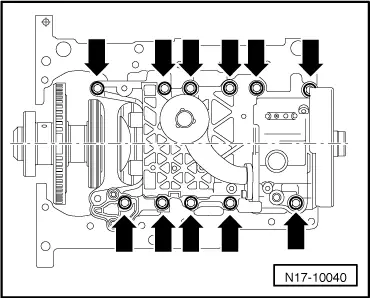

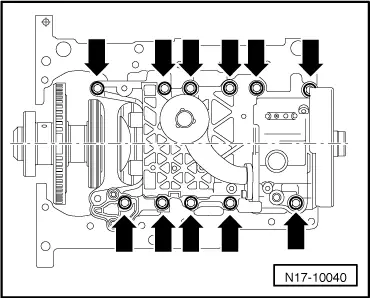

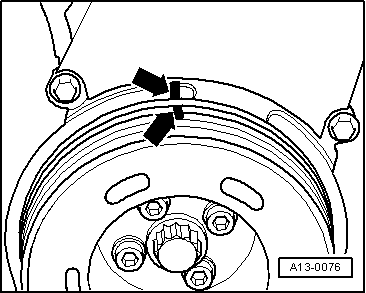

| Loosen bolts -arrows- on balance shaft assembly, working from outside inwards, and then remove balance shaft assembly. |

| –

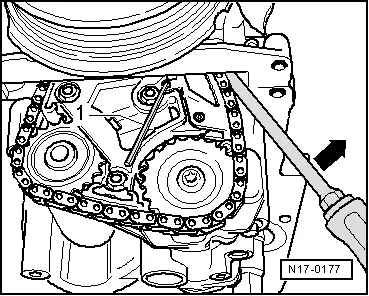

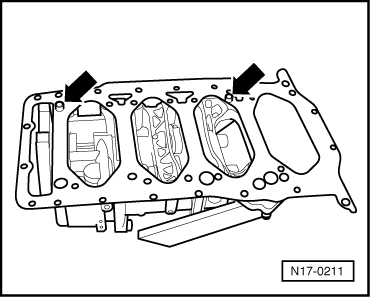

| Remove intermediate plate. |

| l

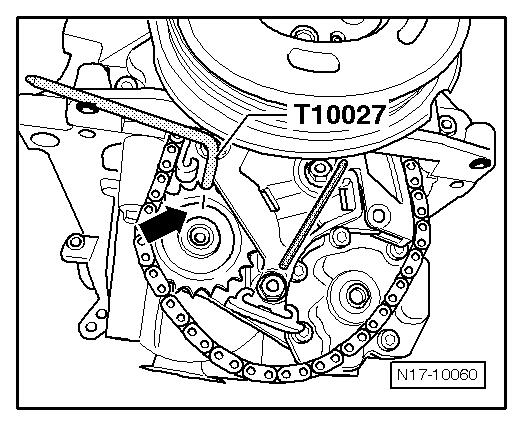

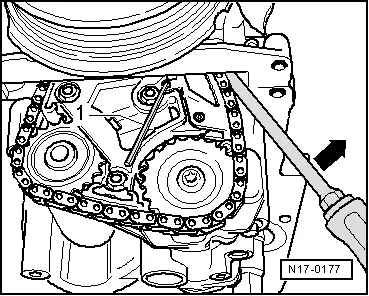

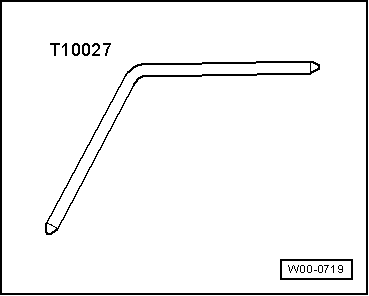

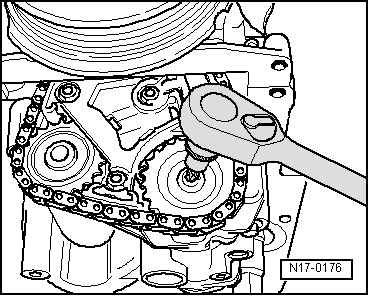

| Chain tensioner must be pre-tensioned → Chapter. |

Note | t

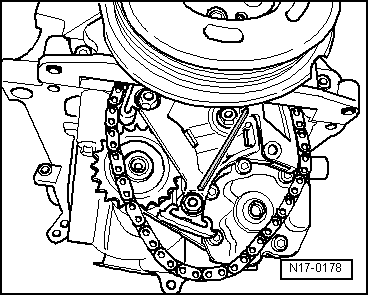

| The intermediate plate must always be renewed. |

| t

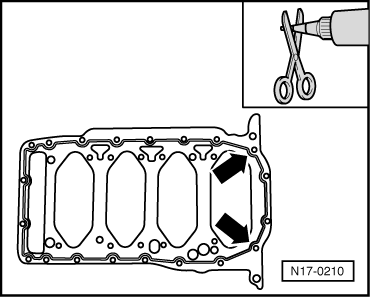

| Note the use-by date of the sealant. |

| t

| The balance shaft assembly with intermediate plate and sump must be installed and the securing bolts tightened immediately after the silicone sealant has been applied. |

| –

| Remove sealant residue from cylinder block using a flat scraper. |

| –

| Cut off tube nozzle at front marking (diameter of nozzle approx. 3 mm). |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note