A3 Mk2

| Pistons and conrods - exploded view |

| 1 - | Conrod bolt, 30 Nm + 1/4 turn (90°) further |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | To measure radial clearance, tighten to 30 Nm but do not turn further |

| 2 - | Pressure relief valve, 27 Nm |

| q | Opening pressure: 1.6...1.9 bar |

| 3 - | Oil spray jet |

| q | For piston cooling |

| 4 - | Conrod bearing cap |

| q | Note installation position |

| q | Due to the cracking method used to separate the bearing cap from the conrod in manufacture, the caps only fit in one position and only on the appropriate conrod. |

| q | Mark cylinder number -B- |

| q | Installation position: Markings -A- face towards pulley end |

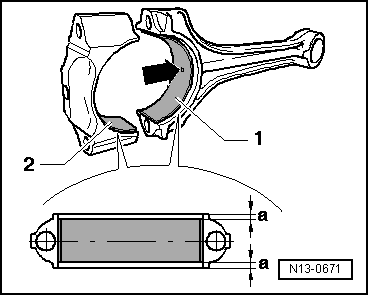

| 5 - | Bearing shell |

| q | Note installation position → Fig. |

| q | Do not interchange used bearing shells |

| q | Measuring axial clearance → Chapter |

| q | Measuring radial clearance → Chapter |

| 6 - | Conrod |

| q | With industrially cracked conrod bearing cap |

| q | Only renew as a complete set |

| q | Mark cylinder number -B- |

| q | Installation position: Markings -A- face towards pulley end |

| 7 - | Circlip |

| 8 - | Piston pin |

| q | If difficult to move, heat piston to 60 °C |

| q | Remove and install using drift -VW 222 A- |

| 9 - | Piston |

| q | Checking → Fig. |

| q | Mark installation position and cylinder number |

| q | Arrow on piston crown points to pulley end |

| q | Install using piston ring clamp |

| q | Checking cylinder bore → Fig. |

| 10 - | Piston rings |

| q | Offset gaps by 120° |

| q | Use piston ring pliers to remove and install |

| q | Marking faces to piston crown |

| q | Checking ring gap → Fig. |

| q | Checking ring-to-groove clearance → Fig. |