| –

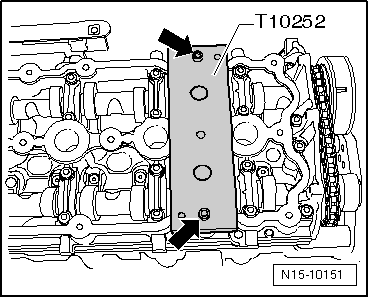

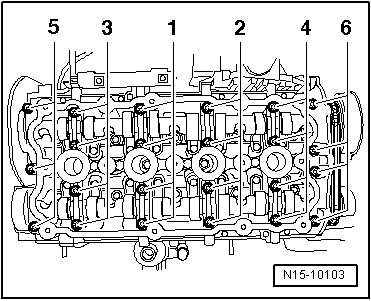

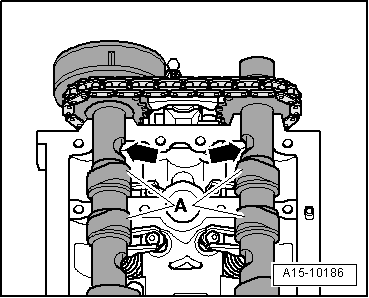

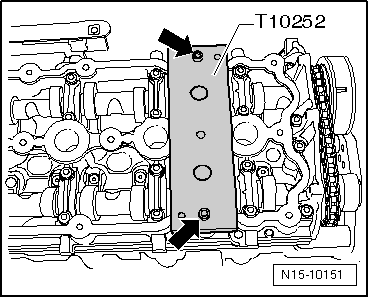

| Then check that camshafts are in TDC position (insert camshaft clamp -T10252- as far as stop). |

Note | t

| If necessary, turn camshafts slightly backwards or forwards when inserting camshaft clamp -T10252-. |

| –

| If it is not possible to insert camshaft clamp -T10252-, retaining frame must be removed and camshafts installed for a second time → Anchor. |

| –

| Detach camshaft clamp -T10252-. |

| –

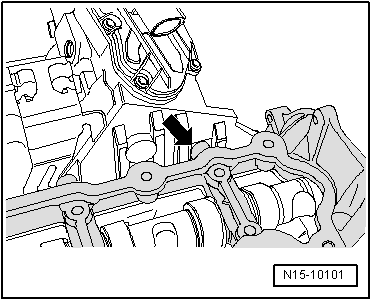

| Drive in cap → Item approx. 1...2 mm deep using thrust piece -3334-. |

| –

| Install toothed belt cover (rear). |

| –

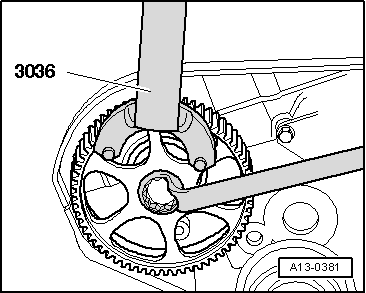

| Insert parallel key into camshaft. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note