A3 Mk2

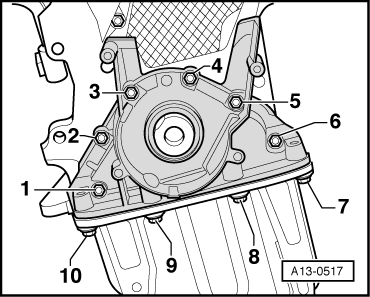

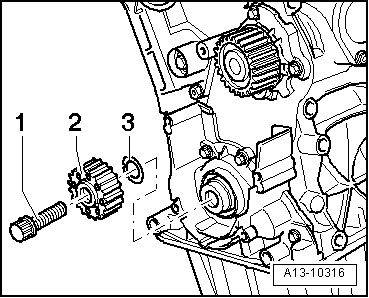

| Removing and installing sealing flange (front) |

| Special tools and workshop equipment required |

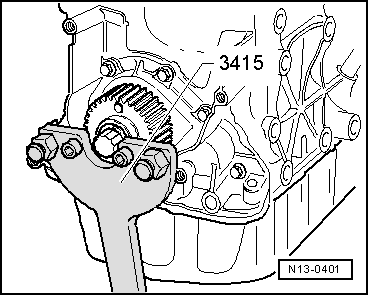

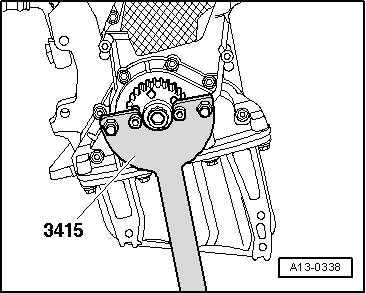

| t | Counterhold tool -3415- |

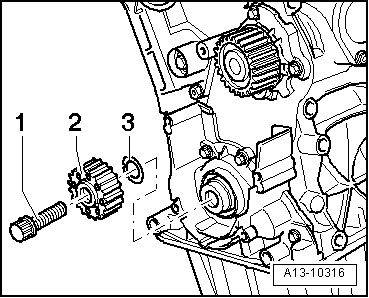

| t | Assembly tool -T10053- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

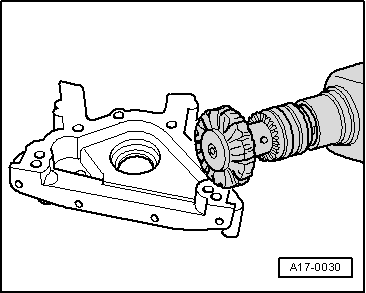

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

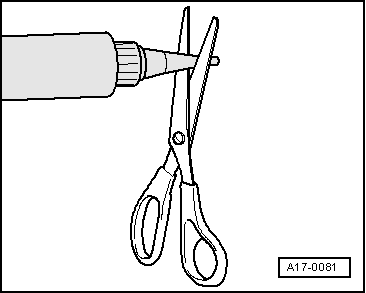

| t | Sealant → Parts catalogue |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

WARNING

WARNING Caution

Caution