A3 Mk2

| Removing engine |

| Special tools and workshop equipment required |

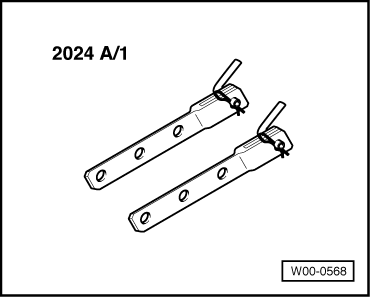

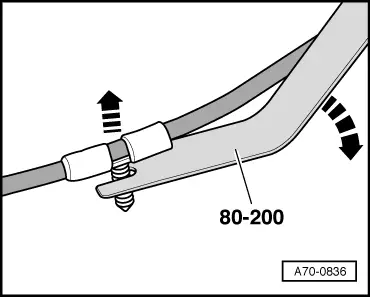

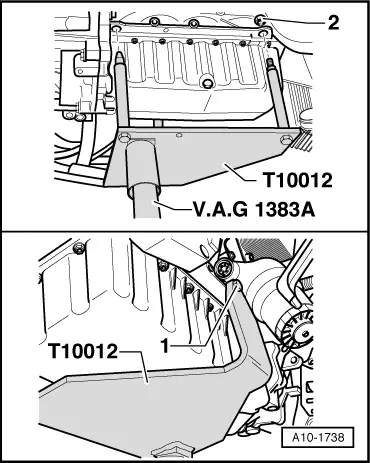

| t | Removal lever -80 - 200- |

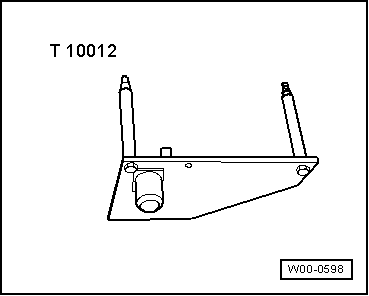

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Stepladder -VAS 5085- |

| t | Drip tray for workshop hoist -VAS 6208- |

| t | Hose clip pliers -VAS 6362- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

WARNING

WARNING Caution

Caution