| t

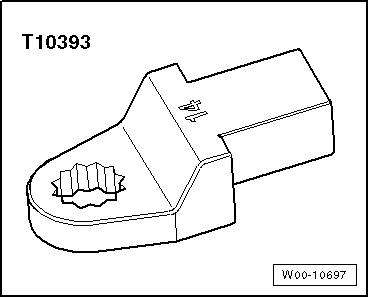

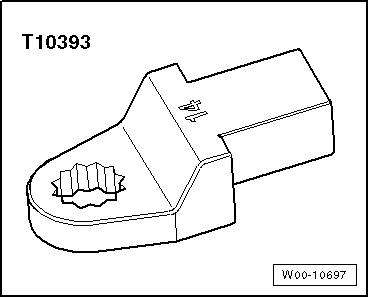

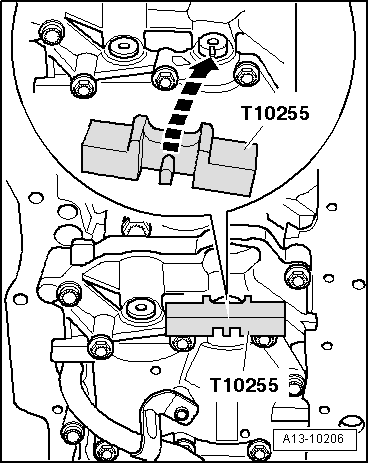

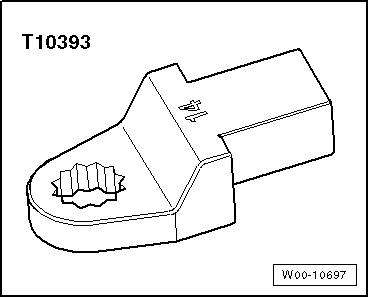

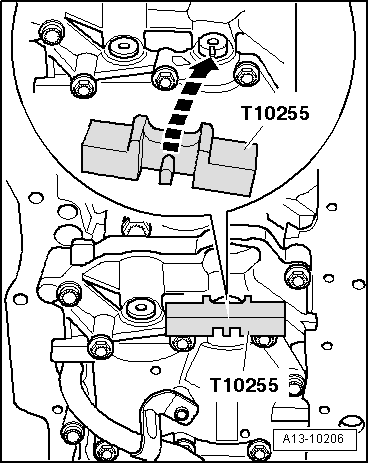

| Insert tool, 14 mm -T10393- |

| l

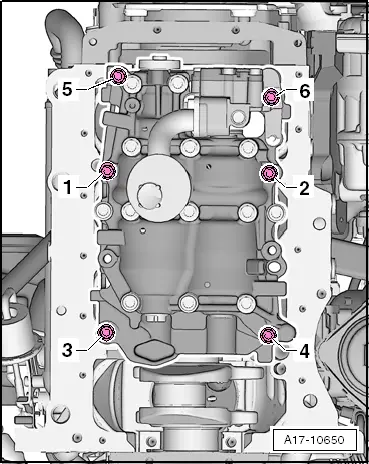

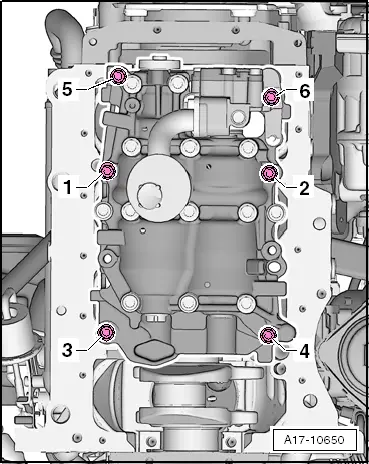

| Crankshaft locked in position with crankshaft stop -T10050-. |

Note | t

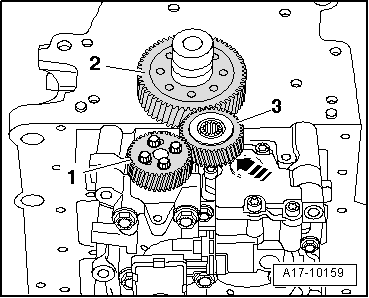

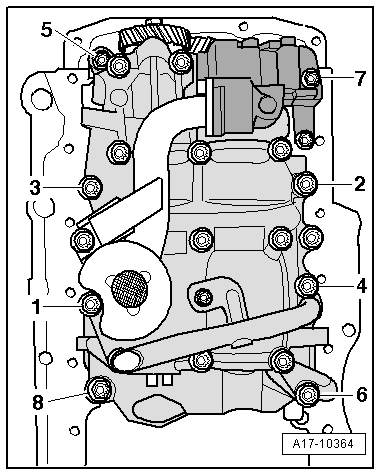

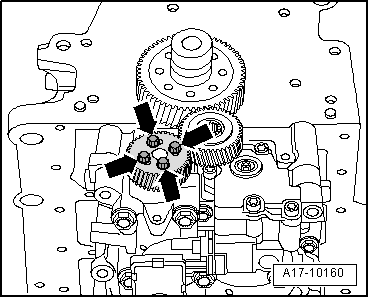

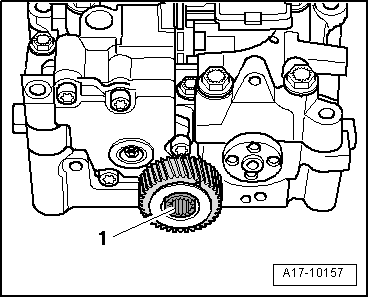

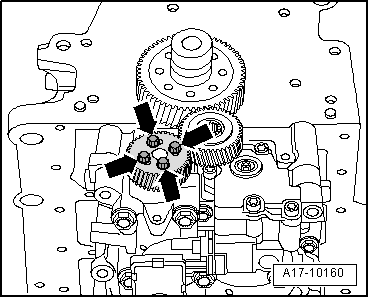

| The spur gear drive of the balance shaft assembly must be installed with a specified backlash. |

| t

| To achieve the correct backlash a coating is already applied to the new idler gear. |

| t

| The coating is worn down rapidly and the backlash is then correct. |

| t

| Therefore, a new balance shaft assembly must always be installed in conjunction with a new idler gear which has the correct coating. |

| t

| Renew the bolts tightened with specified tightening angle. |

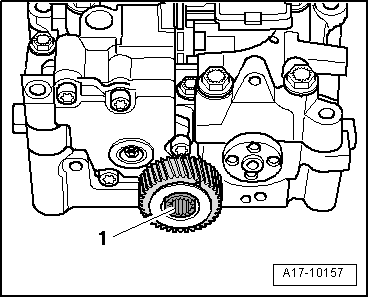

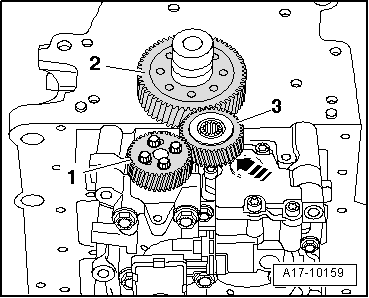

Caution | Thrust washer can slip out of position behind idler gear. |

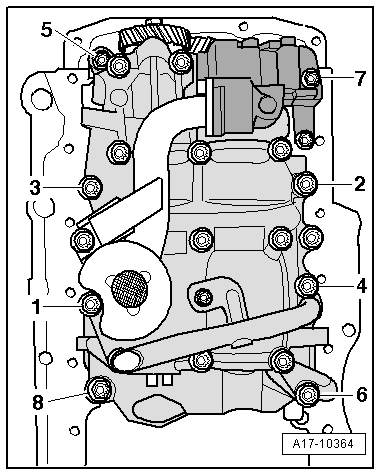

| Before positioning balance shaft assembly, slacken off bolt for idler gear as specified below, but not further. Installation position of thrust washer → Fig. |

|

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note