| –

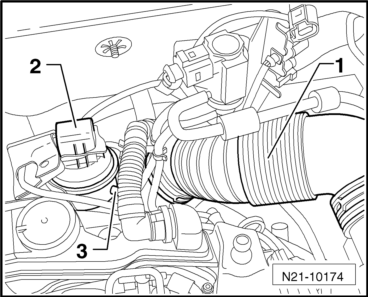

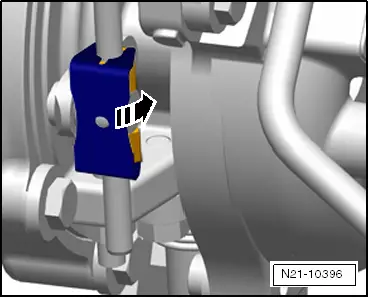

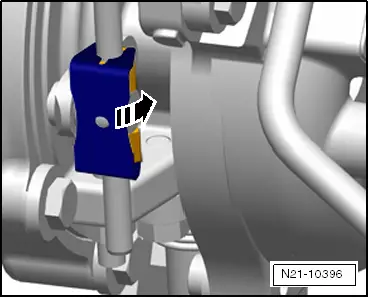

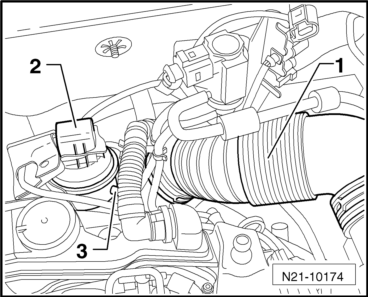

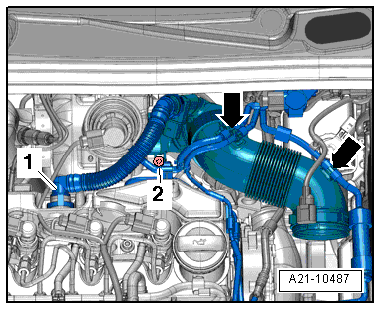

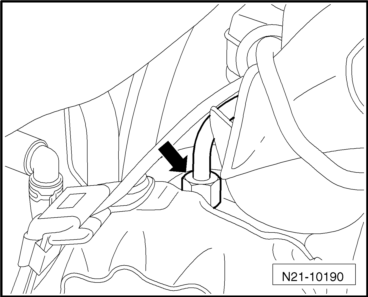

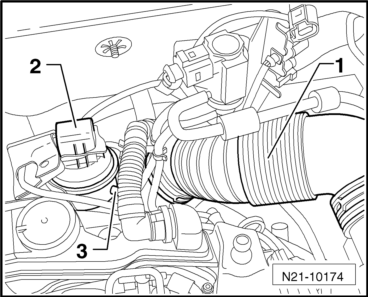

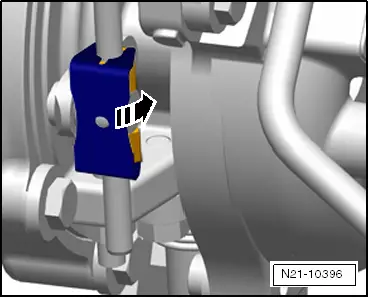

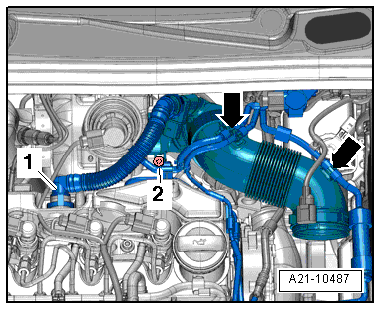

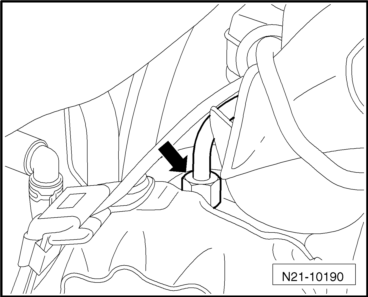

| Plug in connector -2- at position sender for charge pressure positioner -G581- and fasten heat shield sleeve. |

| –

| Connect vehicle diagnostic tester. |

| Selecting operating mode: |

| –

| On touch screen, press button for „Vehicle self-diagnosis“. |

| Selecting vehicle system: |

| –

| On touch screen, press button for „01 - Engine electronics“. |

| The display will show the identification and coding of the engine control unit. |

| Selecting diagnostic function: |

| –

| On touch screen, press button for „011 - Measured values“. |

| –

| On the numeric keypad, enter measured value block „120“ and confirm your entry with „Q“ key. |

| –

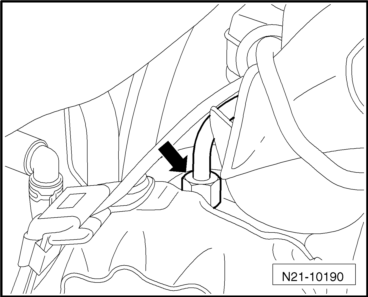

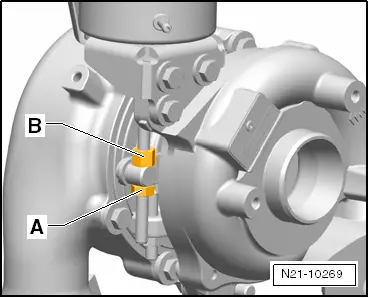

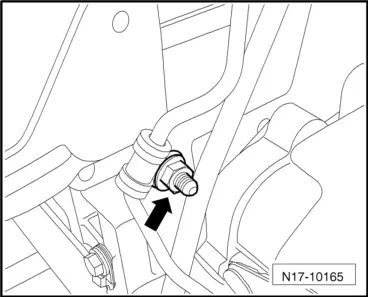

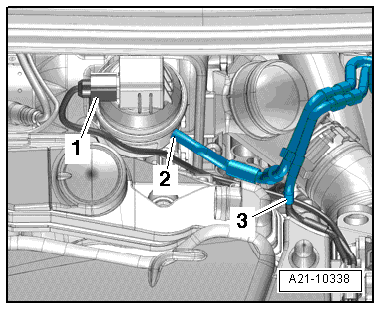

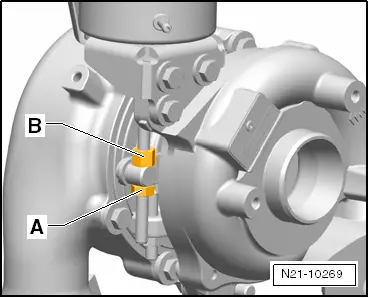

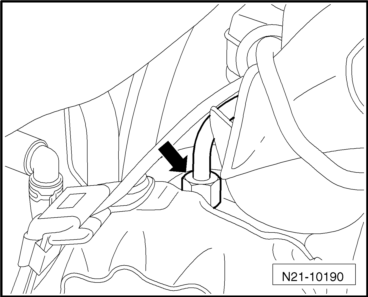

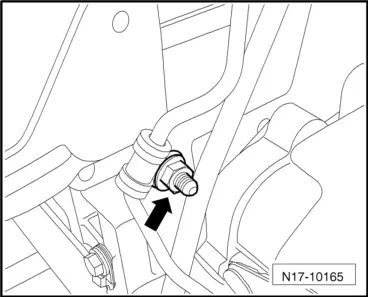

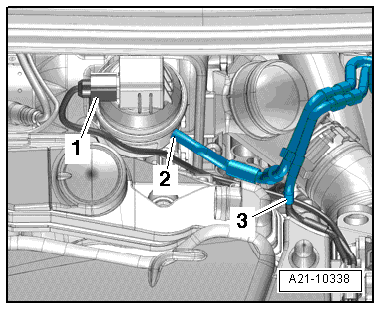

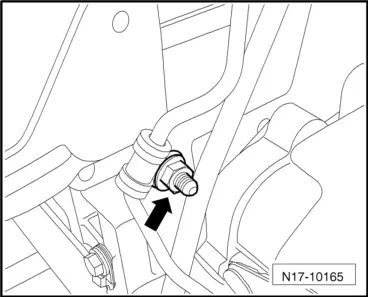

| Connect hand vacuum pump -VAS 6213- to vacuum unit. |

| –

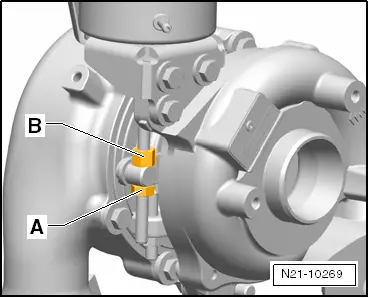

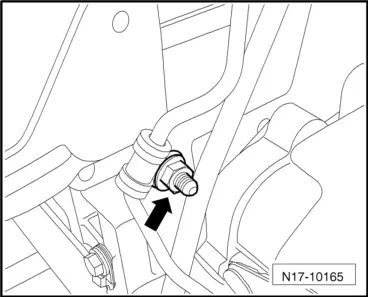

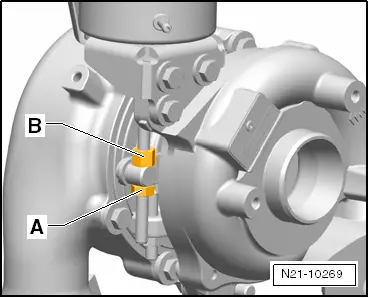

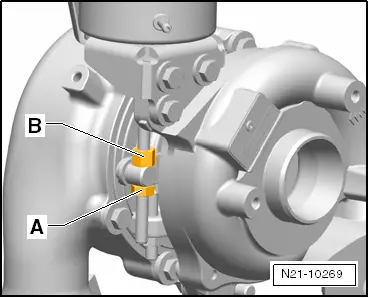

| Create voltage of 0.760 V by generating a vacuum (observe minimum value of measured value block). |

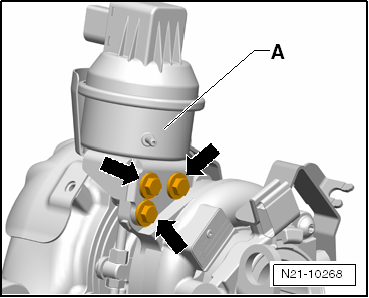

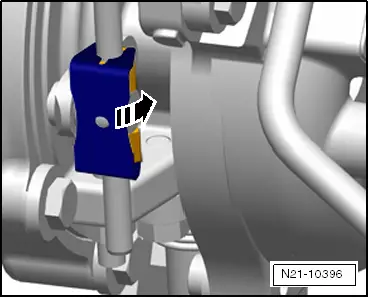

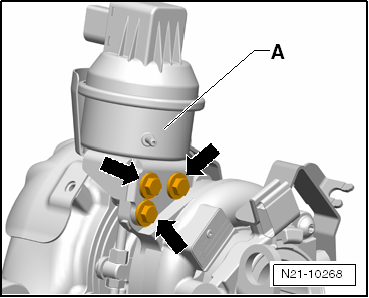

Caution | During the following adjustment procedure for the control rod, the vacuum and the voltage of 0.760 V must be maintained. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note