| –

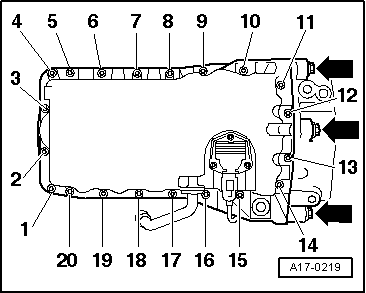

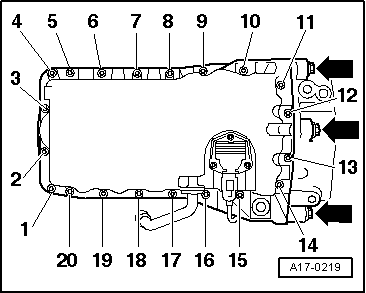

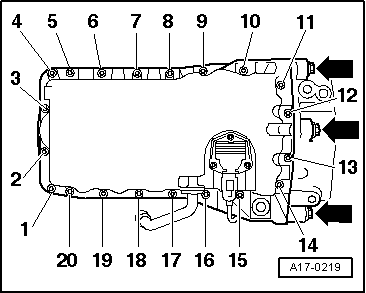

| Immediately install sump and tighten bolts in the following sequence: |

| 1.

| Tighten bolts -1 ... 20- securing sump to cylinder block in diagonal sequence initially to 5 Nm. |

| 2.

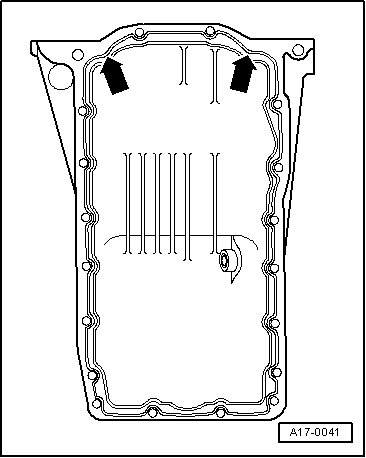

| Tighten bolts securing sump to gearbox -arrows-. |

| 3.

| Tighten bolts -1 ... 20- in diagonal sequence. |

Note | t

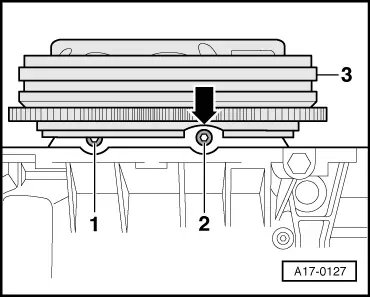

| When installing sump with engine removed from vehicle, ensure that sump is positioned flush with cylinder block at flywheel end. |

| t

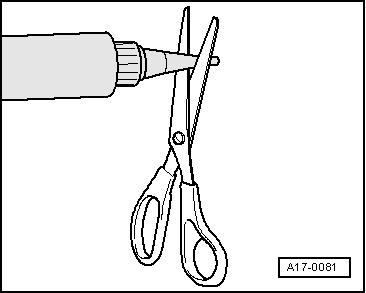

| After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING