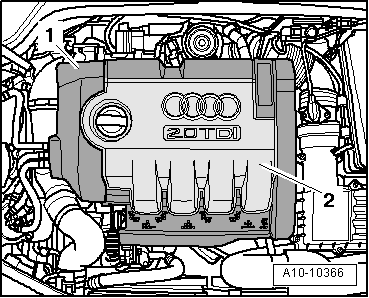

A3 Mk2

Note

Note |

|

|

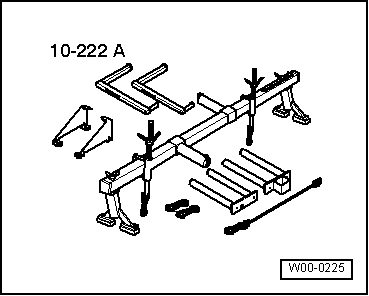

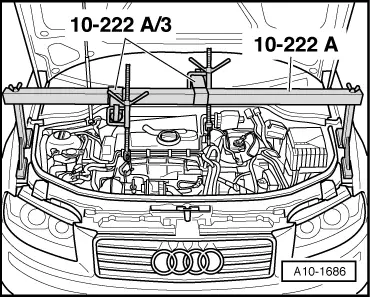

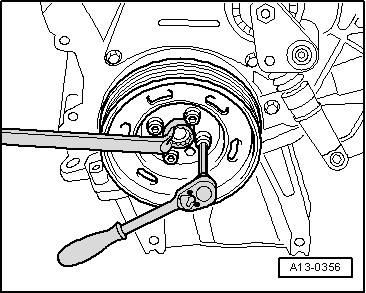

| Special tools and workshop equipment required |

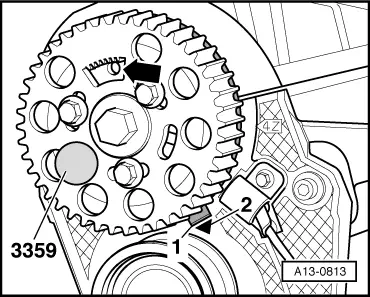

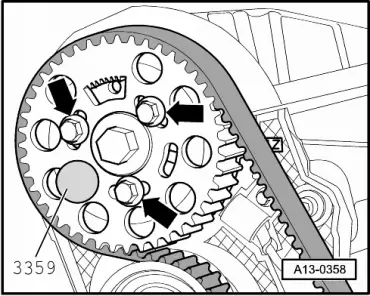

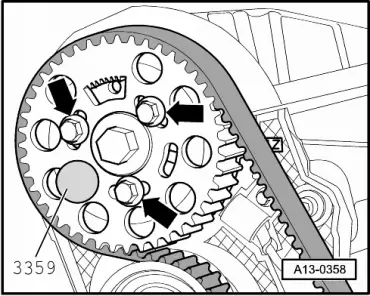

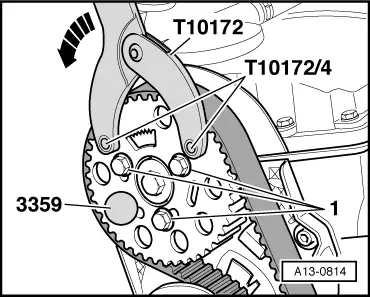

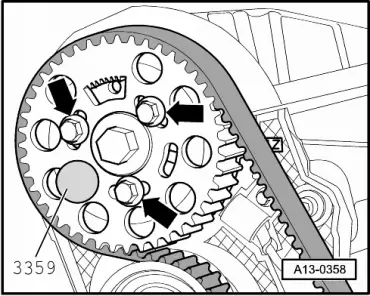

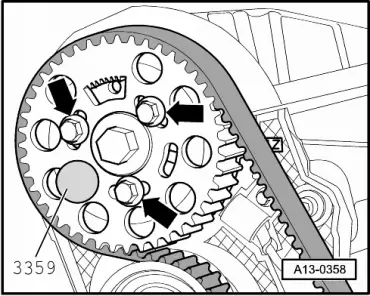

| t | Locking pin -3359- |

| t | Engine bung set -VAS 6122- |

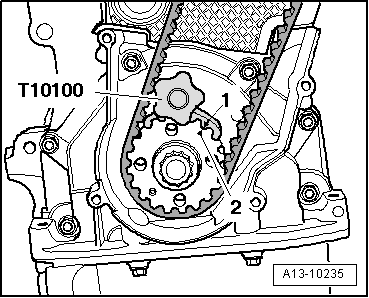

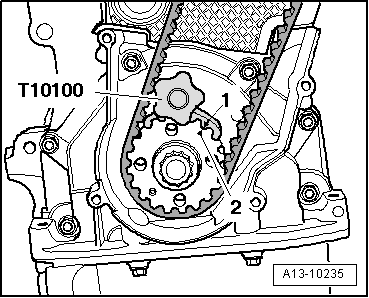

| t | Crankshaft stop -T10100- |

| t | Counter-hold tool -T10172- with pin -T10172/4- |

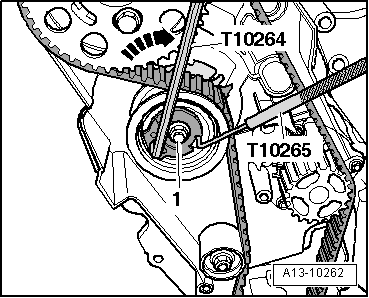

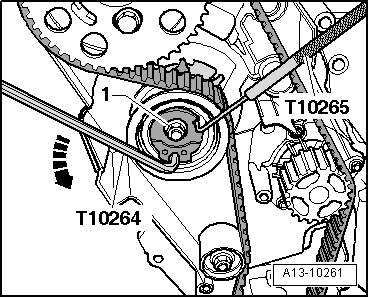

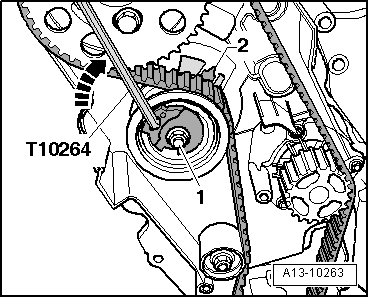

| t | Angle driver -T10264- |

| t | Locking tool -T10265- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | ||

| Tensioning roller for toothed belt to cylinder head | 20 + 45° | ||

| Camshaft sprocket to hub | 25 | ||

| Toothed belt cover (bottom) to cylinder block | 10 1) | ||

| Toothed belt cover (centre) to cylinder block | 10 1) | ||

| Tensioner for poly V-belt to bracket for ancillaries | 23 | ||

| Air pipe (right-side) to bracket | 8 | ||

| |||

WARNING

WARNING Caution

Caution