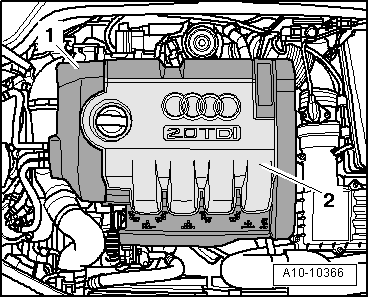

A3 Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

| Component | Nm | ||

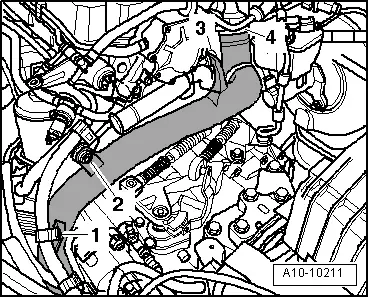

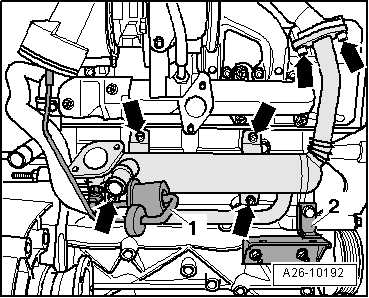

| Oil return pipe to turbocharger | 15 | ||

| Exhaust gas recirculation cooler to: | Intake manifold | 22 | |

| Cylinder block | 10 | ||

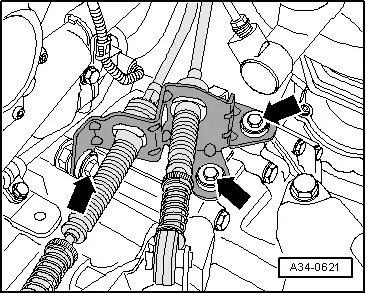

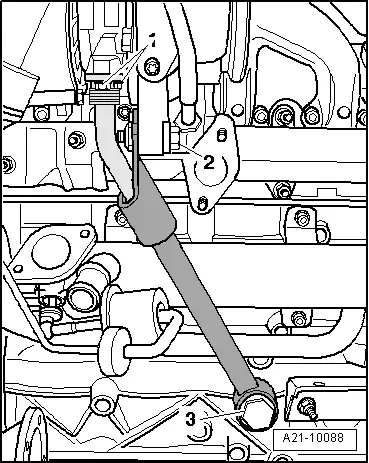

| Support for turbocharger to: | Turbocharger | 25 | |

| Cylinder block | 60 | ||

| EGR connecting pipe to: | Exhaust gas recirculation cooler | 22 | |

| Exhaust manifold | 25 | ||

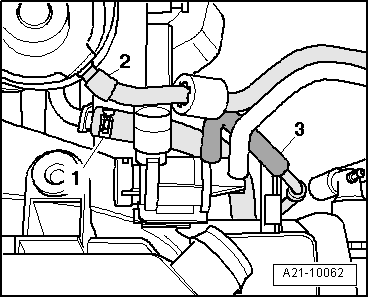

| Underbody cross member (front) to body | 23 | ||

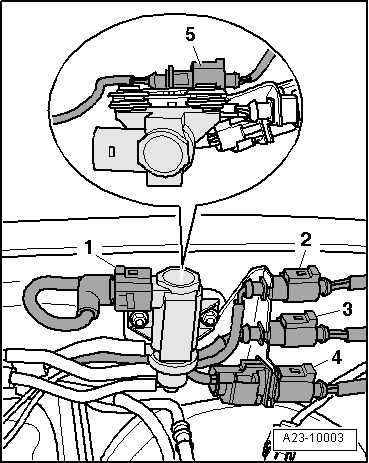

| Air pipe (left-side) to bracket | 8 | ||

Caution

Caution WARNING

WARNING