| –

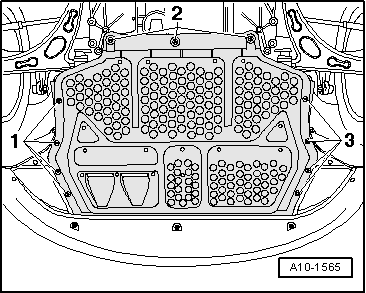

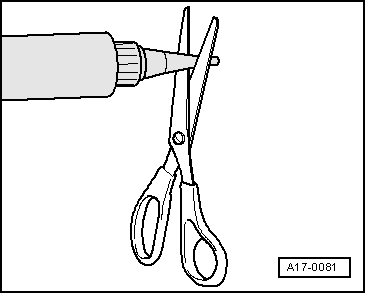

| Immediately install sump and tighten bolts in the following sequence: |

| 1.

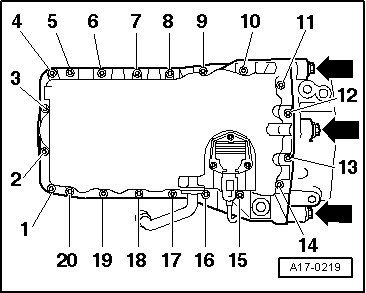

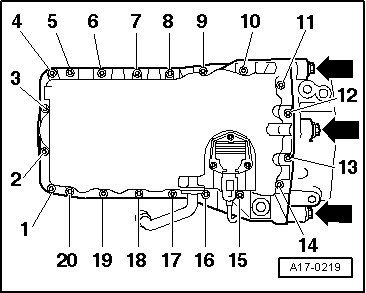

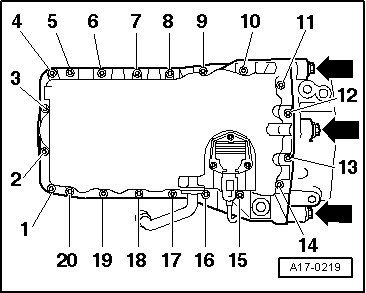

| Tighten bolts -1 ... 20- securing sump to cylinder block in diagonal sequence initially to 5 Nm. |

| 2.

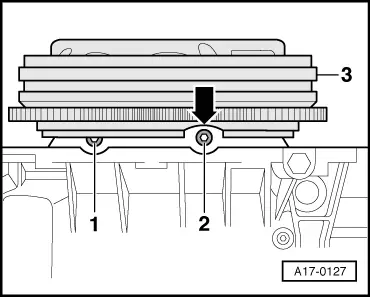

| Tighten sump/gearbox bolts -arrows- to 45 Nm. |

| 3.

| Tighten bolts -1 ... 20- in diagonal sequence to 15 Nm. |

Note | t

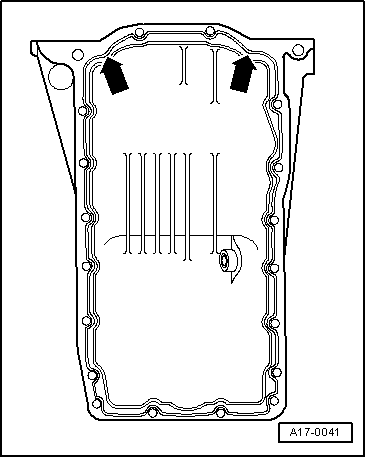

| When installing sump with engine removed from vehicle, ensure that sump is positioned flush with cylinder block at flywheel end. |

| t

| After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

| –

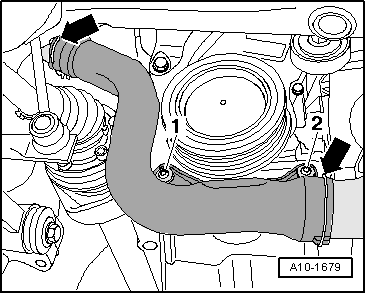

| Install air pipes/hoses with plug-in connectors → Chapter. |

| –

| Fill up with engine oil and check oil level → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING