A3 Mk2

| Pistons and conrods - exploded view |

| 1 - | Conrod bolt, 30 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | Use old bolts when measuring radial clearance |

| 2 - | Conrod bearing cap |

| q | Mark cylinder number -B- |

| q | Installation position: Markings -A- face towards pulley end |

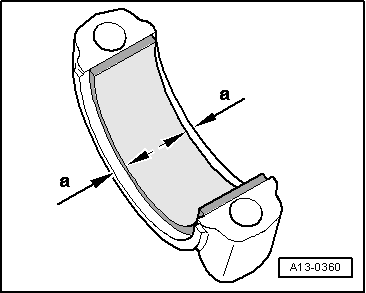

| 3 - | Bearing shell |

| q | Installation position → Fig. |

| q | Do not interchange used bearing shells (mark positions) |

| q | Note type: upper bearing shell (closest to piston) is made of more wear-resistant material. Distinguishing feature on new bearing shells: black marking on bearing surface near joint |

| q | Check that it is securely seated |

| q | Axial clearance: wear limit: 0.37 mm |

| q | Measuring radial clearance → Chapter |

| 4 - | Conrod |

| q | Only renew as a complete set |

| q | Mark cylinder number -B- |

| q | Installation position: Markings -A- face towards pulley end |

| 5 - | Circlip |

| 6 - | Piston pin |

| q | If difficult to move, heat piston to approx. 60 °C |

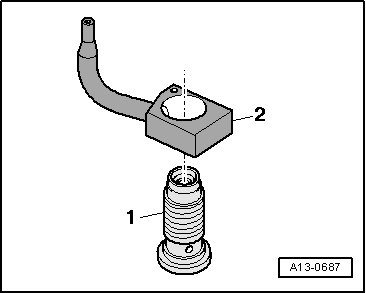

| q | Remove and install using drift -VW 222 A- |

| 7 - | Piston |

| q | With combustion chamber |

| q | Mark installation position and cylinder number |

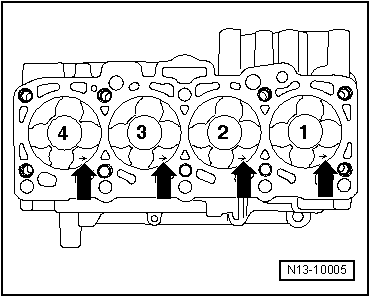

| q | Installation position and allocation of piston/cylinder → Fig. |

| q | Arrow on piston crown points to pulley end |

| q | If cracking is visible on piston skirt, renew piston |

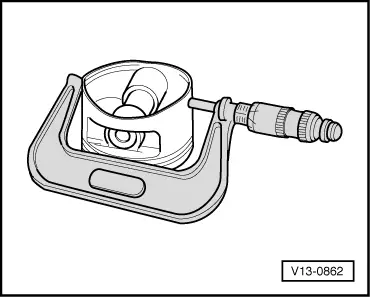

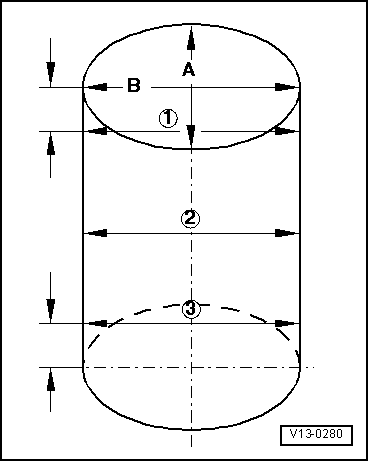

| q | Checking piston → Fig. |

| q | Piston and cylinder dimensions → Chapter |

| q | Checking cylinder bore → Fig. |

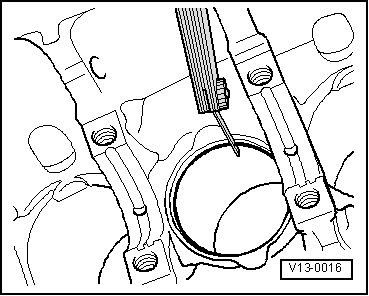

| q | Install using piston ring clamp |

| q | Checking piston projection at TDC → Chapter |

| 8 - | Piston rings |

| q | Compression rings |

| q | Offset gaps by 120° |

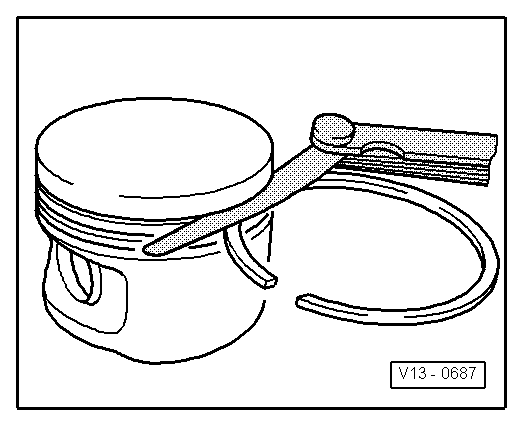

| q | Use piston ring pliers to remove and install |

| q | Marking “TOP” or inscription must face piston crown. |

| q | Checking ring gap → Fig. |

| q | Checking ring-to-groove clearance → Fig. |

| 9 - | Piston ring |

| q | Oil scraper ring |

| q | Offset gap 120° from bottom compression ring |

| q | Use piston ring pliers to remove and install |

| q | Checking ring gap → Fig. |

| q | Checking ring-to-groove clearance → Fig. |

| Piston ring (in mm) | New | Wear limit |

| 1st compression ring | 0.25 … 0.40 | 1.00 |

| 2nd compression ring | 0.25 … 0.40 | 1.00 |

| Oil scraper ring | 0.25 … 0.50 | 1.00 |

|

|

| Piston ring (in mm) | New | Wear limit |

| 1st compression ring | 0.06 … 0.09 | 0.25 |

| 2nd compression ring | 0.05 … 0.08 | 0.25 |

| Oil scraper ring | 0.03 … 0.06 | 0.15 |

|

|

|

|

|

|

|

|

|

|