A3 Mk2

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

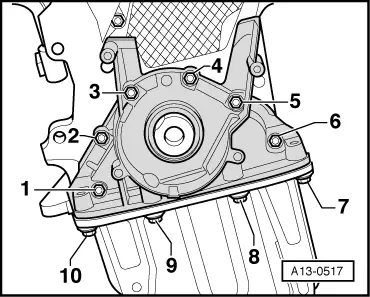

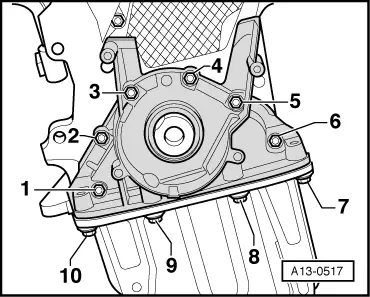

| Component | Nm | ||||

| Sealing flange to cylinder block | 15 | ||||

| Toothed belt sprocket to crankshaft | 120 + 90° 1)2) | ||||

| |||||

WARNING

WARNING