| –

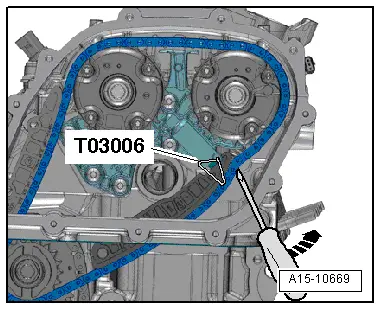

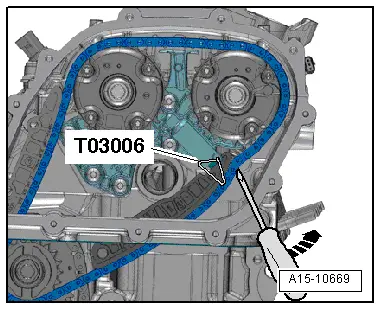

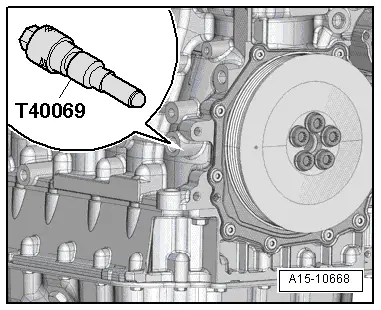

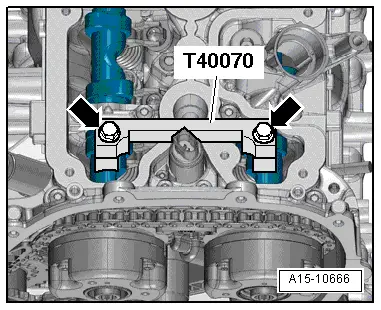

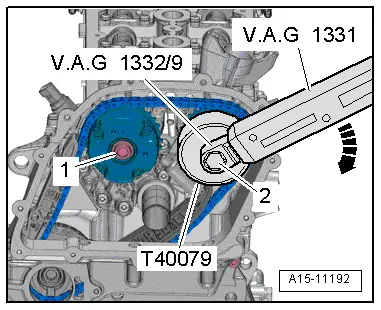

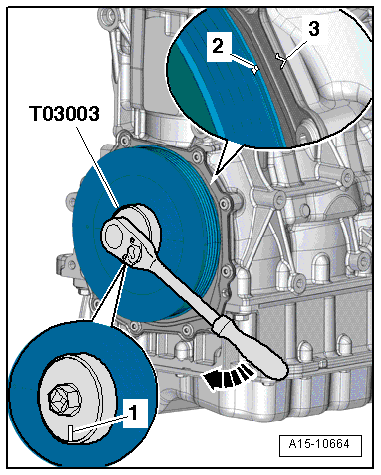

| Press guide rail of chain tensioner for camshaft timing chain inwards as far as the stop using a screwdriver. Then lock chain tensioner by inserting locking pin -T03006-. |

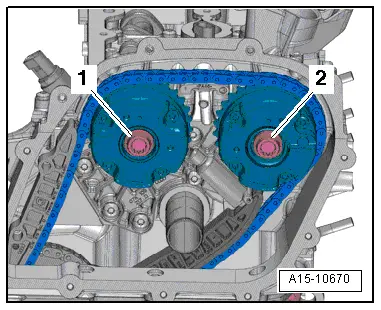

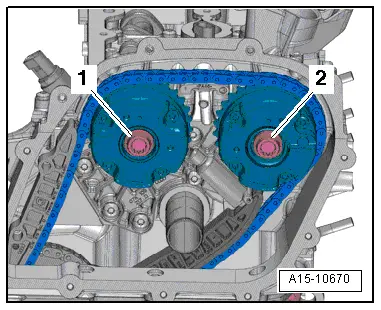

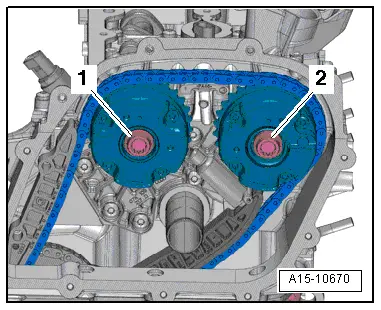

Caution | If a used timing chain rotates in the opposite direction when it is refitted, this can cause breakage. |

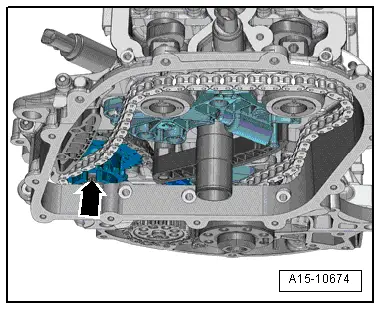

| Mark running direction of timing chain with coloured arrows for re-installation. Do not mark timing chain by means of centre punch, notch or the like. |

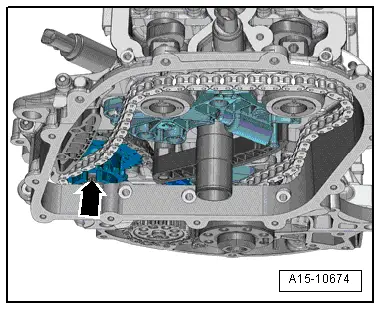

| Risk of irreparable damage to engine. |

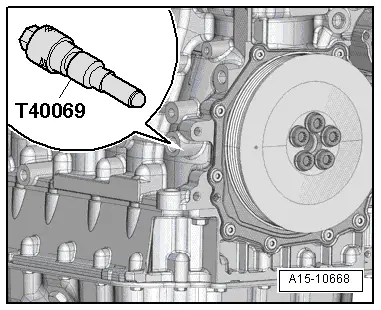

| Block off the opening in the valve timing housing with a clean cloth to prevent small items from dropping into the engine. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution