A3 Mk2

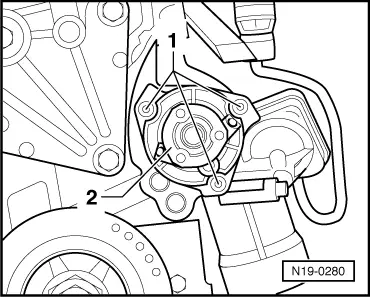

| Removing and installing coolant pump |

| Special tools and workshop equipment required |

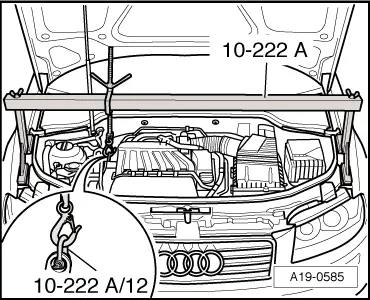

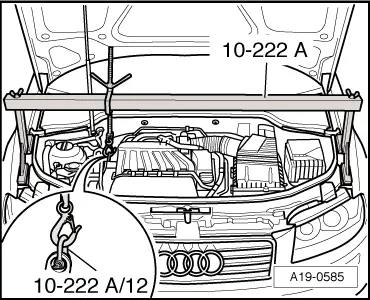

| t | Support bracket -10-222 A- |

| t | Shackle -10-222 A/12- |

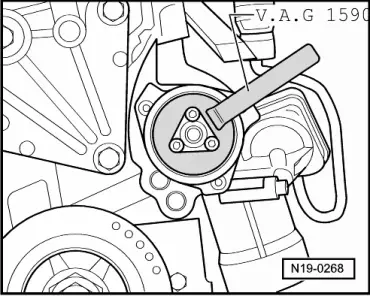

| t | Water pump spanner -V.A.G 1590- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Drip tray for workshop hoist -VAS 6208- |

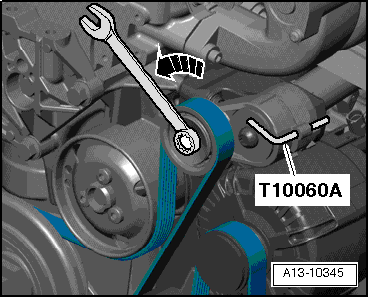

| t | Locking pin -T10060 A- |

| t | Bolt M8x40 |

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

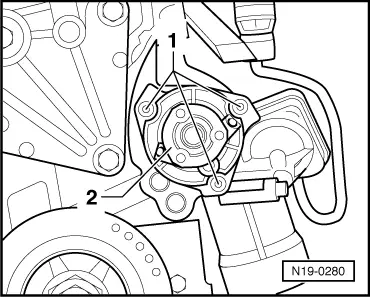

| Component | Nm |

| Coolant pump to cylinder block | 8 |

| Pulley to coolant pump | 20 |

WARNING

WARNING